History

Taiyo Kogyo Corporation was founded in 1922 as Nohmura Tent Shokai, and later restarted with a single sewing machine and a pair of scissors amidst the burnt ruins of the postwar period. Since our founding, we have been introducing unique products that take advantage of the characteristics of membrane materials, based on our desire to "contribute to society as much as possible and deliver excitement to as many people as possible."

1922 (Taisho 11)

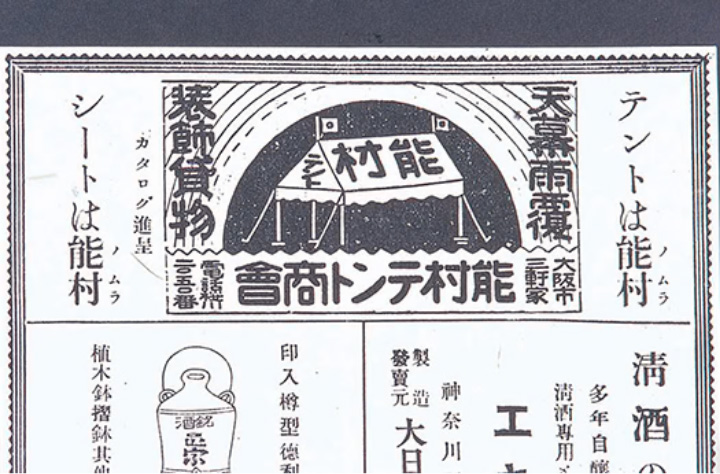

Founded by Kinshige Noumura as Noumura Tent Shoukai,

Then, the business was closed down under the Wartime Enterprise Improvement Act.

Founded in 1922 by Kinshige Nomura (grandfather of Kotaro Nomura, the third president) as "Nomura Tent Shokai" in Taisho Ward, Osaka City. The company actively introduced new technologies in the development of its products. Among these, the "Modern Tent," developed in 1929 as a camping tent, was a product that used an inflated bicycle tube as a prop and covered it with cotton fabric, and was the prototype for today's air-beam type of air membrane structure. However, the company was forced to close down in 1943 due to the promulgation of the Enterprise Improvement Law following the escalation of World War II.

1946 (Showa 21)

Founded Taiyo Kogyo Co.

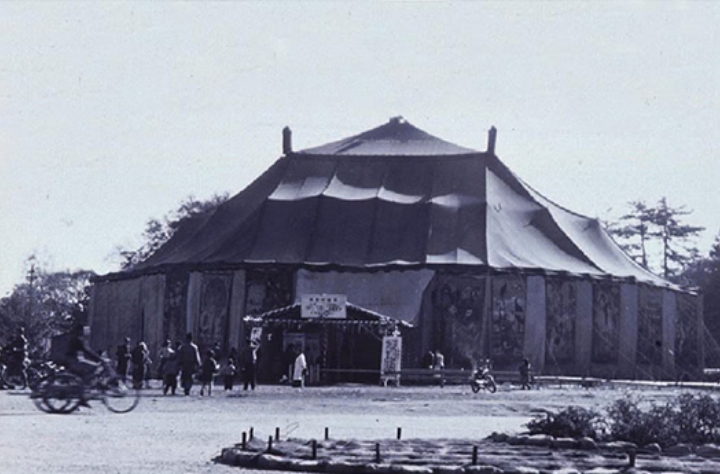

In 1946, after the defeat in the war, Ryutaro Nomura (father of Kotaro Nomura) rebuilt the business as "Nomura Sewing Works" with a single foot-pedal sewing machine and a pair of scissors. The following year, in 1947, the company was reorganized as a joint-stock corporation, and its name was changed to the current Taiyo Kogyo Corporation. In the same year, Hiromasa Nomura (brother of Ryutaro Nomura) joined the business and expanded it to the manufacture and installation of interior decorations, theater and cinema curtains and curtains, and eventually, with the birth of new synthetic fibers, the company began to manufacture large tents. The first of these was the large tent (length: 37.8 m, width: 46.8 m) for the Kinoshita Circus, which was designed and manufactured in 1956, and several other large tents were completed after much trial and error.

1955 (1955)

Spun off rental tents and interior decorating division and established

Taiyo Tent Co.

Receives large orders for the covers for Daihatsu's three-wheeled "Midget" auto trucks.

In addition to manufacturing the tops for Daihatsu Motor Co.'s three-wheeled midget, Taiyo Kogyo's vinylon sheets for coarse bedding were used in large quantities to restore a large levee breach caused by Typhoon Isewan in 1959, playing a pioneering role in the development of geotextiles in Japan.

1964 (Showa 39)

Three companies, Taiyo Kogyo, Tokyo Taiyo, and Taiyo Kagaku, merge to form

New Taiyo Kogyo.

Anticipating the trend toward containers in transportation, the company has started development and sales of flexible container bags (product name: Ticon) and anti-pollution membranes (product name: Silt Protector) to prevent the spread of pollution in marine civil engineering projects, thereby expanding its business base.

1970 (1970)

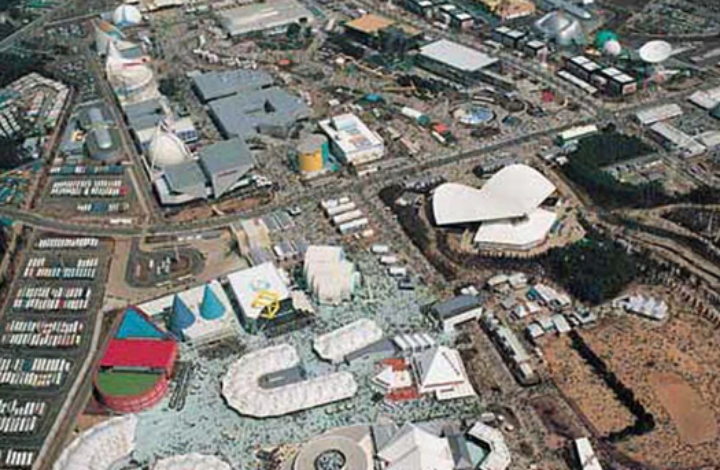

Osaka Expo held. Constructed many pavilions.

Blooming tents at the Japan World Exposition,

changed the concept of large membrane structures.

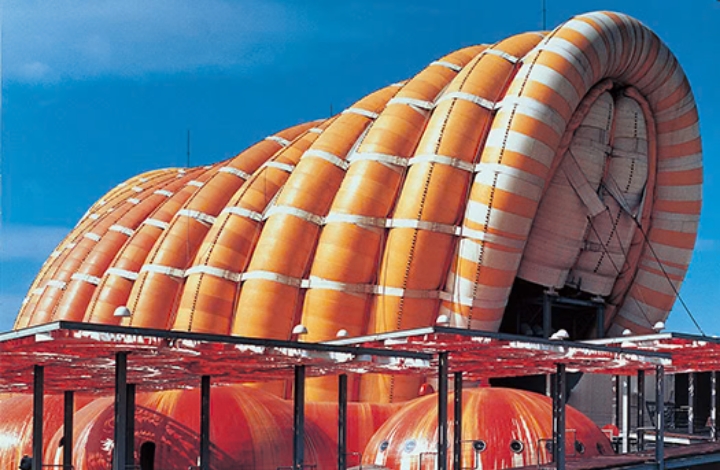

As a result, various tent structures (membrane structures) were realized at the 1970 World Exposition in Osaka, Japan, as a means of large-space construction. Unprecedented tent structures were created, including the "America Pavilion," the world's first giant air membrane structure with a low rise, and the Fuji Group Pavilion, a saddle-shaped dome (air beam system) made by connecting 16 tubes 4 meters in diameter and 60 meters long. The "America Pavilion," in particular, was later adopted as the structural system for the huge stadiums that became the rage in the United States.

1975 (1975)

Okinawa International Ocean Expo was held.

Constructed many pavilions.

1985 (1985)

Science Expo Tsukuba '85 held. (The second exposition boom arrived.)

Many pavilions were constructed.

1988 (1988)

Nara Silk Road Expo and Sea and Islands Expo (Hiroshima) held.

Constructed many pavilions.

1988 (1988)

Tokyo Dome completed.

(Roofing membrane manufactured and installed onsite at our company, prime contractor is Takenaka Corporation).

In 1987, under the provisions of Article 38 of the Building Standard Law, membrane structural buildings based on the technical standards for specific membrane structural buildings were generally approved, and their use as permanent buildings began in Japan. The Tokyo Dome (designed by Nikken Sekkei Ltd. and Takenaka Corporation; built by Takenaka Corporation), for which we manufactured and constructed the membrane roof, was completed in 1988, and since then, membrane structures have been used for covered grounds in snowy regions, including the Akita Sky Dome (designed and built by Kajima Corporation) in 1990. Since then, membrane structures have been adopted for roofed grounds in snowy regions, including the Akita Sky Dome (designed and built by Kajima Corporation) in 1990.

1992 (1992)

Established the Nomura Foundation for Membrane Structure Technology.

Acquires 100% of the stock of Bird Air, Inc. of the U.S.

In 1992, Bird Air, the largest manufacturer of membrane structures in the U.S., became a wholly owned subsidiary of the company, and since the bursting of the bubble economy in Japan, the company has expanded its base of operations to Asia, Oceania, and Europe. In China, the company has been particularly active in the business, starting with the substand at the Shanghai International Circuit, and has established a design, manufacturing, and construction system in China. Meanwhile, in Japan, we manufactured and installed the roofs of stands at Saitama Stadium 2002 and five other stadiums for the 2002 Soccer World Cup, which was co-hosted by Japan and South Korea, and our achievements were highly evaluated. In subsequent tournaments in Germany, South Africa, and Brazil, we participated in projects in each country.

1993 (Heisei 5)

Ryutaro Nomura was awarded the Order of the Sacred Treasure, 3rd class.

2000 (Heisei 12)

The world's largest dome

in London, England, the "Millennium Dome" membrane roof was constructed.

2001 (Heisei 13)

Hirakata Plant,

Obtained "ISO9002" quality system certification (audit registration).

2005 (Heisei 17)

Developed plant-derived and renewable membrane materials for Expo 2005 Aichi, Japan.

Adopted by various facilities.

2011 (Heisei 23)

Participated in a plan to cover the Fukushima Daiichi Nuclear Power Plant (Unit 1) with a membrane at the reactor building cover tent

and

played a role in the containment of the situation.

2016 (2016)

Completed

"MakMax FLEX EXPERIENCE CENTER" at the Osaka Head Office as a facility where visitors can experience membrane structures.

2020 (2020)

Medical Negative Pressure Tent to increase production for outpatient fever

and supply to medical facilities.

2023 (2023)

Employees of three Taiyo Group companies are merging

New "Osaka Campus" location completed

-

1922 (Taisho 11)

Founded by Kinshige Noumura as Noumura Tent Shokai, later closed down under the Wartime Enterprise Development Act.

-

1946 (Showa 21)

Founded Taiyo Kogyo Co.

-

1947

Established Taiyo Kogyo Co.

-

1955 (1955)

Spun off rental tents and interior decorating division as a separate company, Taiyo Tent Co.

-

1964 (Showa 39)

Three companies, Taiyo Kogyo, Tokyo Taiyo, and Taiyo Kagaku, merge to form New Taiyo Kogyo.

-

1967 (Showa 42)

U.S. representative office is established in New York.

-

1970 (1970)

Hosted the Osaka Expo (changed the concept of large membrane structures).

-

1971 (Showa 46)

Acquisition of Holcomb, Inc. stock in the U.S. and full-scale entry into the U.S. market begins.

-

1983 (Showa 58)

Head office building completed.

-

1988 (1988)

Completion of Tokyo Dome (roofing membrane manufactured and installed onsite by Takenaka Corporation, prime contractor).

-

1992 (1992)

Established the Nomura Foundation for Membrane Structure Technology. Acquires 100% of the stock of Bird Air, Inc. of the U.S.

-

1993 (Heisei 5)

Ryutaro Nomura was awarded the Order of the Sacred Treasure, 3rd class.

-

1997 (Heisei 9)

Bird Air acquires 100% of the shares of

Stromeyer & Wagner, a leading German tent manufacturer. -

2000 (Heisei 12)

Established Taiyo Kogyo (Thailand) Co.

-

2001 (Heisei 13)

Hirakata Plant obtains "ISO9002" quality system certification (audit registration).

-

2002 (Heisei 14)

Mizuho Plant obtains "ISO9002" quality system certification (audit registration).

Established Shanghai Taiyo Kogyo Membrane Co. -

2003 (Heisei 15)

Establishment of "THAI TAIYO TENT CO.,LTD" in Thailand.

TAIYO KOGYO acquires 100% of the shares of SHADE STRUCTURES BIRDAIR Pty. LTD. in Australia and changes the company name to

"TAIYO MEMBRANE CORPORATION, INC".

TAIYO BIRDAIR CORPORATION is established in the United States. -

2004 (Heisei 16)

Obtained "ISO9001" quality system certification (audit registration) for the design, manufacture and construction of tent warehouses.

TAIYO MEMBRANE CORPORATION, INC. established

TAIYO MEMBRANE CORPORATION-MIDDLE EAST LLC in Dubai.

TAIYO EUROPE GmbH was established in Germany. -

2005 (Heisei 17)

Established INTERNATIONAL TAIYO TRADING PTE. LTD. in Singapore.

-

2006 (Heisei 18)

Established "MakMax HD, LLC" in the United States.

-

2008 (Heisei 20)

Established Taiyo Enesys Co.

-

2013 (Heisei 25)

Established Taiyo Kogyo (Cambodia) Co.

Established PT. Taiyo Kogyo Indonesia in Indonesia. -

2016 (2016)

MakMax FLEX EXPERIENCE CENTER" was completed at the Osaka Head Office.

-

2022 (2022)

Yumi Nomura appointed President and Representative Director

-

2023 (2023)

Completion of the Osaka Campus, a new location where employees of the three Taiyo Group companies are merged.

- TOP>

- Corporate Information>

- History