Taiyo Kogyo Column

Explains the benefits of implementing a WMS, the role of vendors, and how to select a specific vendor.

2024.01.30

When implementing a WMS, many staff members may wonder what kind of vendor they should hire. In this article, we will explain the roles of vendors when implementing a WMS, how to select a specific vendor, and vendor checkpoints. We hope you will find this information useful in order to select the vendor that best suits your company and to implement a WMS smoothly.

Advantages of implementing a WMS

WMS is a warehouse management system that streamlines logistics operations. First, let us introduce the advantages of implementing a WMS.

Preventing gerrymandering.

Warehouse management involves many tasks performed by employees, such as receiving and shipping, issuing forms, and inventory control. Therefore, even with care, human errors such as discrepancies in inventory counts and erroneous shipments can occur.

A WMS enables centralized control of the number of items received, the number of items in stock, and other figures necessary for warehouse management, thereby preventing shipment omissions and slip errors. Some WMSs also provide alert notifications when a wrong operation is made and provide appropriate instructions, which reduces the likelihood of human error.

A WMS will also ensure that a certain level of quality is maintained regardless of who performs warehouse management tasks. It will help to move away from an operation that relies on skilled workers and make it easier to hand over tasks and assign responsibilities.

Can improve operational efficiency

Warehouse management operations are faced with increasing logistics volume and a chronic shortage of human resources, making operational efficiency a major challenge. A WMS can improve operational efficiency from the following perspectives

- Real-time grasp of incoming and outgoing shipments and inventory status eliminates unnecessary checks.

- Visualization of employee work status allows clear instructions to be given.

- Eliminates the need for manual slip entry and returns processing

For example, a WMS allows you to check work status and inventory counts in real time. It eliminates the need to visually check the status of incoming and outgoing shipments, as was the case in the past, and to make calculations to grasp the current status and consider necessary instructions. In this way, a WMS can improve the efficiency of the entire warehouse management operation.

Cost Reduction

Warehouse management involves a variety of processes, so the work must be shared among many people. However, the more people involved, the higher the cost, so keeping labor costs down has been a challenge.

A WMS can automate or simplify some of the tasks that were previously performed by a single person. For example, the filling out of vouchers and instructions can be automated, which will lead to a reduction in labor costs.

In addition, a WMS will standardize warehouse management operations and may reduce costs associated with training new employees. The difference between skilled and new employees can be easily bridged, and limited personnel can work more efficiently.

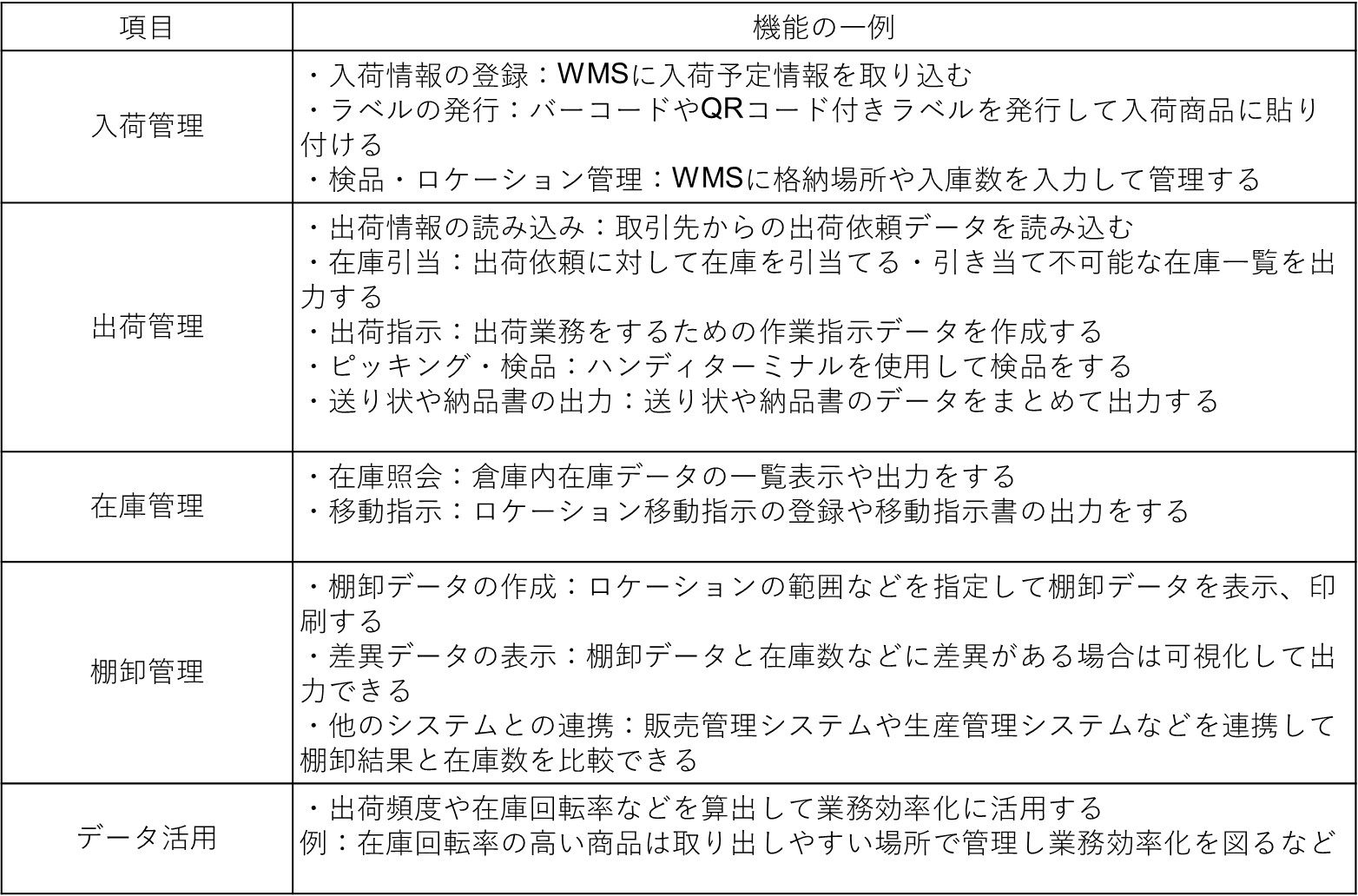

List of basic functions of WMS

WMS can manage a series of logistics operations from receiving to shipping. Currently, barcodes and QR codes are the mainstream, but in the future, the use of AI, cameras, and other digital technologies is expected to increase.

Role of the vendor when implementing a WMS

When implementing a WMS, it is common to work with a vendor. Here are some examples of the roles vendors play when implementing a WMS.

Able to clarify current issues

Having a vendor present during the implementation of a WMS allows for a clear understanding of your company’s issues. If you have been conducting warehouse management operations in the same way for many years, your in-house personnel alone may not be aware of problems.

For example, if the following situations are taken for granted within the company, they will not be recognized as points that need to be improved.

- There are tasks that can be simplified.

- Certain employees are overburdened.

- Many overlapping tasks.

Therefore, a vendor with knowledge of the logistics industry will review your current situation and identify your company’s issues. By examining what can be improved with a WMS based on the issues, a valuable WMS implementation can be realized.

Propose systems and functions that fit your company's needs.

Currently, there are differences among WMS systems, and functions are not standardized. Therefore, the WMS to be selected depends on the size of the warehouse, the products to be managed, and the frequency of receiving and shipping.

In a situation without knowledge of the WMS, you may not be able to select an appropriate system and achieve the desired results.

Therefore, vendors with knowledge of the logistics industry will select the necessary functions and systems based on the current issues. You can introduce all the necessary functions for your company’s warehouse management without omission and avoid mistakes in WMS selection.

Perform pre-installation testing and manual preparation.

If a problem occurs during the introduction of a WMS, logistics operations may be delayed and products may not be delivered to customers. It is important to carefully prepare for the introduction of a WMS to ensure that it can operate without problems, as this will affect the company’s credibility.

Vendors are responsible not only for system development, but also for advancing implementation preparations such as pre-implementation testing and manual preparation. If any problems are found during pre-implementation test runs, the vendor will not only continue to make improvements, but will also provide support for data migration and internal penetration.

There is no point in introducing a WMS if it cannot be used within the company without problems. We utilize the knowledge and expertise that only a vendor can provide, and prepare the foundation for in-house operation.

Provide post-implementation support

Vendors do not end with the implementation of the WMS, but also provide support afterwards. The post-implementation support varies from vendor to vendor, but as an example, the following support is available.

- 24-hour trouble support

- Modification and customization of functions after WMS implementation

- Security measures

The logistics industry is susceptible to changes in the external environment and business conditions. It is possible that shipping units or service levels may change from the situation at the time of introduction. At such times, vendors will be consulted to propose improvement methods and additional functions.

How to choose a vendor when implementing a WMS

In this section, we will explain how to choose a vendor when implementing a WMS in an easy-to-understand manner. You will know what to look for when choosing a vendor.

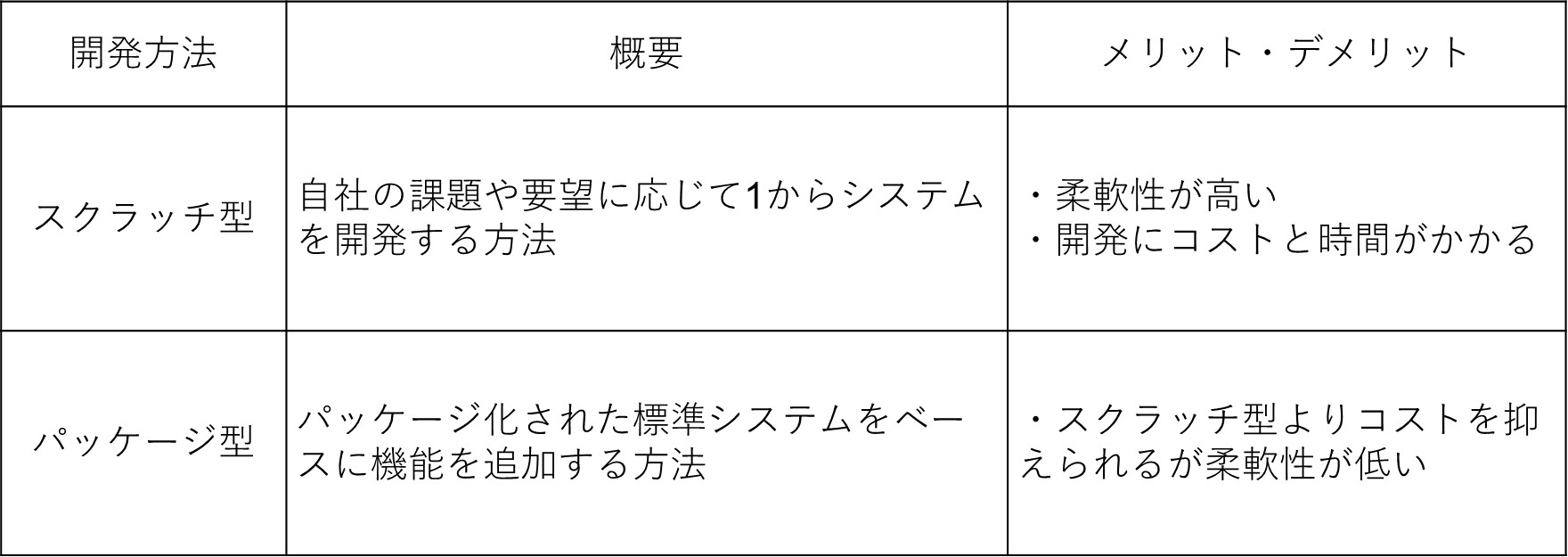

development method

There are two main development methods for WMS

The scratch type is a method of developing a system from scratch based on your company’s issues and requirements. Since an original WMS is developed, it is highly flexible and can be used for highly specialized industries or when special functions are required.

The package type is a method of adding functions based on a pre-prepared standard system. The advantage of this method is that it is less costly and can be implemented in a shorter period of time than the scratch type.

Thus, customizability and cost will vary depending on which development method the vendor supports, so be sure to check in advance.

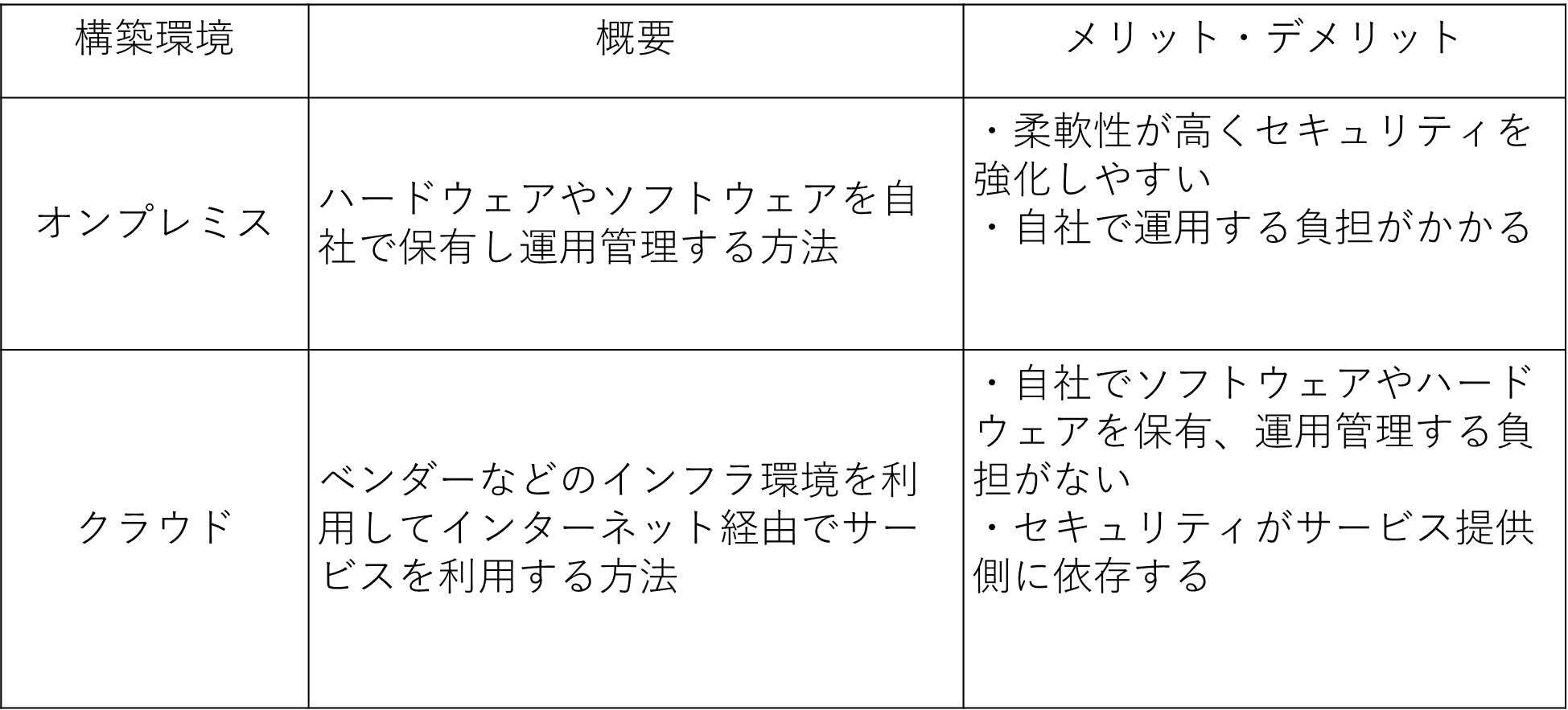

Construction Environment

There are two types of WMS build environments: on-premise and cloud.

On-premise is a method of setting up the infrastructure environment, including hardware and software, in-house. The advantage is that you can build an environment that fits your company’s needs, such as enhanced security and integration with other systems. On the other hand, it requires personnel who can build, maintain, and manage the infrastructure environment in-house.

Cloud computing is a method of using services via the Internet using the infrastructure environment of a vendor or other organization. The advantage of this method is that there is no burden to build, maintain, and manage the infrastructure environment in-house.

Since initial costs, running costs, and security differ between on-premise and cloud computing, it is important to check the construction environment supported by the vendor.

Introduction Results

When selecting a WMS vendor, look at the following implementation experience.

- Has a track record of implementation in the same industry and at the same scale as the company

- We have experience in WMS-specific customization

- We have extensive experience in implementing WMS in other industries, and have the knowledge and track record to provide peace of mind.

Different WMS vendors have different areas of expertise and experience in different industries. For example, if you are considering implementing a WMS for garments, a vendor with extensive experience in customization and examples from the same industry may be able to make suggestions based on industry characteristics and trends.

In addition, there are many cases where vendors handle WMS but have other core products or core businesses. It is recommended to check the extent to which the vendor has experience with WMS only, rather than with all products, so that you can feel confident in your request.

Linkage of other systems

If the WMS cannot be integrated with other systems, it may not lead to sufficient business efficiency improvement, etc. In order to utilize the system from a medium- to long-term perspective with DX promotion, etc. in mind, it is important to confirm whether the vendor supports integration with other systems. Examples of other systems include the following

- Cooperation with logistics robots (e.g., shelf-transport robots and cooperative transfer robots)

- Integration with core systems and OMS (Order Management System)

- Linkage with video data

For example, if the system can be linked to a logistics robot that provides picking assistance, the data obtained from picking can be shared seamlessly. As the change in work styles progresses, the use of digital tools in the logistics industry is expected to advance. If you hire a vendor with scalability in anticipation of the future, you will be able to respond flexibly when the need arises.

Cost-effective

It is important to expect a certain level of cost-effectiveness from a WMS. To this end, select a vendor that can clarify your company’s issues and make appropriate proposals to address them. For example, if you have an issue of reducing labor costs, you cannot expect cost-effectiveness unless you have a clear idea of how much labor costs can be reduced by implementing a WMS.

It is also important to have the costs at the time of implementation and running costs clearly presented; even if a WMS can achieve certain results, if the running costs are too high, it will not be cost-effective.

There is a device that is easy to penetrate within the company.

If you have employees who are familiar with WMS, it is easy to spread it within the company, but in most cases, there is no one in the company who is familiar with WMS.

Therefore, it is also important that the vendor provides the following support to help the WMS penetrate within the company.

- Support for manual creation

- Conduct workshops and training

- Post-system updates

For example, simply having training provided at the time of WMS implementation can save the time and effort of planning and managing in-house training, while building an environment in which the WMS can be used.

Smooth communication.

Since the implementation and operation of a WMS takes a certain amount of time to tackle, if you cannot communicate smoothly with the vendor, the project will not proceed as planned. In order to determine whether the vendor is a suitable partner with whom you can work side by side, check the following points.

- When you contact the person in charge, you get a reply within a short time.

- They explain technical terms in an easy-to-understand manner.

- Ability to listen and make proposals.

- Knowledgeable about their industry

In particular, if there is a sense of speed in responding to inquiries, it is possible that they are thinking about your company and not putting it on the back burner. If the person in charge responds with enthusiasm, you can rest assured that your company will be in good hands.

After-sales support is in place.

WMSs are often improved and updated after implementation, depending on the situation at the site. To ensure stable and long-term operation, select a vendor that has the following after-sales support in place.

- Response in case of errors or problems

- Regular updates

- Post-introduction improvement proposals

In particular, an environment that can respond to the addition of new functions, integration with other systems, updates, etc., after the WMS has been implemented, will allow for optimal operation according to future circumstances.

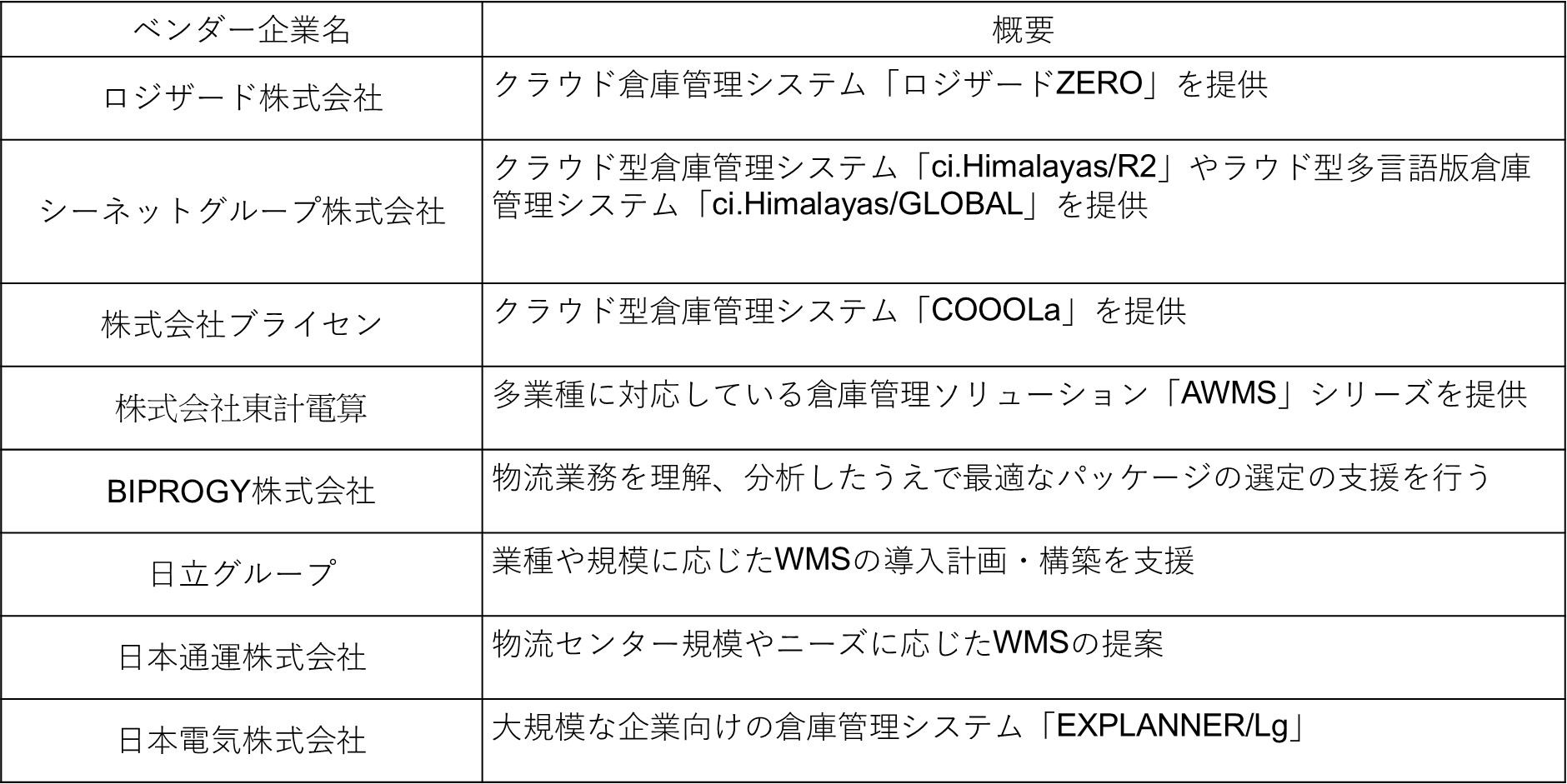

An example of a WMS vendor company

The following is a sample of WMS vendor companies in Japan. Since each vendor company offers different systems and services, please use them as a reference when looking for a vendor that fits your company’s needs.

WMS vendors can be chosen through a competition.

If it is difficult to narrow down to one WMS vendor, a competition can be held to select the vendor that best suits your company.

In a competition, we will review proposals, quotes, and presentations from several vendors before making a final decision on which vendor to request. The advantage of conducting a competition is that it allows us to compare proposals and quotes from multiple vendors. This allows the selection of a vendor based on an understanding of each vendor’s strengths, proposal capabilities, and costs, thereby preventing mismatches in vendor selection.

One disadvantage would be the time and effort required to select a vendor; if you are in a hurry to implement a WMS, a competition may take too long.

Since vendor selection will determine the outcome of your WMS implementation, consider a competition if you want to carefully consider which vendor is the best fit for your company.

Points to consider when selecting a WMS vendor

Here are three points to check when selecting a WMS vendor. Knowing them before selecting a vendor will make it easier to find the right vendor for your company.

I have a proposal that can solve the current problem.

First, choose a vendor that understands the current issues and can make proposals. Analytical and listening skills are required to understand current issues.

You will also need to have the knowledge and experience to propose how the WMS can be used to solve current issues. Please confirm whether your company’s issues can be solved by looking at the proposals made by the person in charge.

Cost and implementation timeframes are clearly defined.

Some vendors may proceed with the discussion with ambiguous timeframes and costs. To avoid regrets such as “the cost was higher than expected” or “it took too long to implement” when the system is actually implemented, ask the vendor to clearly present the cost and implementation period from the estimate stage.

Especially in the area of cost, it would be helpful to clarify not only the installation cost, but also the running and maintenance costs.

Comprehensive coverage of WMS functions

If a WMS is not equipped with functions that match the company’s business type and operations when it is implemented, it will not produce the desired results.

Especially in the case of packaged or cloud-based systems, it is important to confirm what standard functions are available and how expandable they are.

They can offer you something extra.

WMS proposals will vary depending on the type of industry, the size of the warehouse, and the nature of the business. It is a good idea to have a proposal that takes into account not only the standard functions, but also your company’s challenges and future prospects.

For example, a proposal to design the system based on the assumption that it will be linked with other systems in the future will provide an image of stable operation over a long period of time.

Advance preparation to find the right WMS vendor for your company

Now that you know what to look for in selecting a WMS vendor, here are some preliminary preparations to help you choose the right vendor for your company. You will find out what you should implement before consulting with a vendor.

Clarify the purpose of implementing a WMS

First, clarify the purpose of why you are considering implementing a WMS. If you can share your objectives with the vendor, it will be easier for the vendor to make a clear proposal. On the other hand, if the purpose of implementation is unclear, it will be difficult to imagine what functions are necessary.

It is advisable to discuss and communicate why a WMS is necessary, for example, “to promote operational efficiency” or “to resolve human resource shortages.”

Establish a budget and timeframe for implementation

Once you have decided to implement a WMS, establish a specific budget and time frame for implementation. Although it depends on the WMS to be introduced, there is generally a certain cost involved at the time of introduction. Simply thinking, “I want to implement it someday,” will put off its implementation.

- Budget available for WMS implementation

- Budget available for WMS operations

- Date and time to complete the WMS implementation

and share it with the vendor, it will be easier to get a proposal that fits your budget and schedule.

Share issues within the company

Once you have decided to implement a WMS, it is a good idea to discuss within your company the issues you faced before and when implementing the WMS. In particular, it is important to hear from the on-site personnel who are actually doing the work.

Will it interfere with employee operations?” “Will it affect other systems?” and “Will it affect other systems?” These and other concerns can be identified and shared with the vendor so that countermeasures can be considered in advance.

In addition, sharing information with employees before the WMS is implemented will make it easier to work together to implement the WMS in a aligned manner.

If you need more warehouse space for inventory work or movement when implementing WMS, leave it to "Taiyo Kogyo"!

When implementing a WMS, you may need to temporarily move or reorganize inventory. When there is not enough warehouse space during inventory clearance, please utilize “Taiyo Kogyo’s” tent warehouse.

Tent warehouses require a shorter construction period than conventional warehouses or system construction warehouses, and can be used at a lower cost. In particular, Taiyo Kogyo’s tent warehouses have the following strengths, and we can offer the best solutions.

Advantages of Taiyo Kogyo’s Tent Warehouses

- Ability to make proposals: Experienced and professional staff will make proposals according to your requests and concerns.

- High quality: We have our own technical research laboratories and various development departments.

- We realize high-quality tent warehouses through various approaches, including our own ISO 9001-certified factory.

- After-sales service: We provide extensive after-sales service from nine locations nationwide, even after delivery.

Utilizing Taiyo Kogyo’s tent warehouses can help reduce costs and improve efficiency when implementing a WMS. Tent warehouses of various shapes and sizes are available depending on the amount of inventory and products handled, so please check them out.

▼ Click here for a list of products and services of Taiyo Kogyo Co.

https://www.tentsouko.com/

Select a vendor that fits your company and solves your problems

When implementing a WMS, it is easier to implement a WMS that will solve your company’s problems if you work with a vendor you can trust.

It is important to get serious from the vendor selection stage by referring to the vendor selection process described in this article and the preparation before selecting a vendor. when your WMS implementation progresses and you need to organize or move your warehouse, check out “Taiyo Kogyo” tent warehouse.

Tent Warehouseへの

Contact us

What you need to know when building a warehouse

We packed it all in.

Clues to solving the 2024 problem

I want to build a warehouse in an economical way.

Which type of warehouse should we build?

I want to learn the basics of warehouse construction anyway.

I'm concerned about the 2024 problem, but I don't know what to do about it.

Related Articles

- TOP>

- Taiyo Kogyo Column>

- Explains the benefits of implementing a WMS, the role of vendors, and how to select a specific vendor.