Taiyo Kogyo Column

Before implementing a WMS! Know the difference between warehouse management and inventory management|Explanation of the main functions, roles, and benefits of WMS.

2024.02.01

Warehousing” and “inventory control” are both operations that manage goods, but do you understand the difference correctly? It is important to know the difference between the two as basic knowledge in order to smoothly implement and operate a WMS.

In this article, we will explain in detail the differences between warehouse management and inventory management, as well as the functions, roles, and benefits of WMS implementation. If you are unsure of the difference between warehouse management and inventory management, or want to know the basics of WMS and warehouse management operations, please check out this article.

Warehouse Management" and "Inventory Control" are often confused.

Warehousing” and “inventory control” are often confused with each other because they are very similar operations. In reality, however, it is necessary to understand the difference because the objects and purposes to be managed are different.

This section details the features and differences between warehouse management and inventory management.

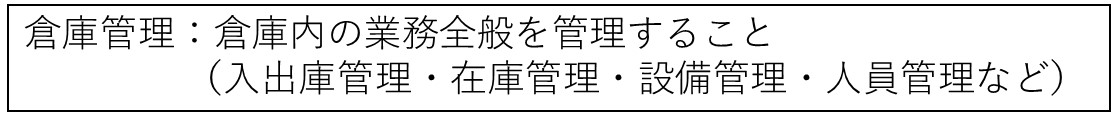

What is Warehouse Management?

Warehouse management is the management of all operations in a warehouse. In addition to warehousing and inventory control, warehouse management also includes the management of the facility environment and personnel.

Typically, the following tasks occur in the warehouse

Warehousing operations

Unloading, collating incoming slips, inspecting, sorting, and shelving

Warehousing operations

Item picking, inspection, packing, collation of outgoing slips, and loading.

Inventory operations

Control inventory counts and storage locations, process orders received and placed

Environmental maintenance related services

Guidance on staffing, facilities management, air conditioning management, and occupational accident prevention

There are many different types of warehouse operations and a wide variety of items that need to be managed. Warehouse management also includes inventory control, as the management of materials and products in the warehouse is also a part of the business.

Purpose of Warehousing

The purpose of warehouse management is to improve the overall efficiency of operations in a warehouse. Proper management of the entire warehouse, including the flow of goods, personnel, and facility environment, reduces errors and waste and improves productivity.

The main objectives of warehouse management can be summarized as follows

- Realization of operational efficiency and cost reduction

- Preventing errors and problems such as shipping delays and erroneous shipments

- Optimization of inventory in warehouses

- Maintain and improve service quality

Sloppy warehouse management can lead to frequent delivery delays due to missing items and operational errors due to lack of information. Accurate warehouse management is essential to stabilize and improve the efficiency of warehouse operations.

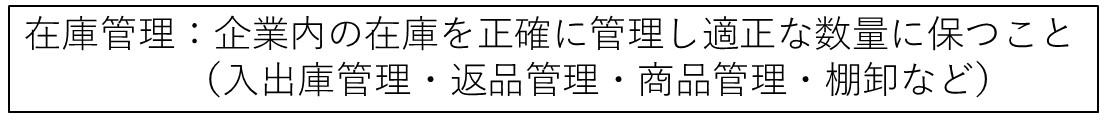

What is inventory control?

Inventory control is to accurately grasp all inventories of raw materials, work in process, products, etc. existing in a company, and to manage them in appropriate quantities and quality. Various types of inventory are properly managed so that necessary items can be supplied in necessary quantities and to necessary locations in light of production volume and sales conditions.

The main tasks of inventory management include receiving and shipping control, returns management, ordering and receiving, and inventory. Details are as follows

Receiving and warehouse management operations

Receiving and processing (recording and controlling items, quantity, date, time, quality, etc.)

Warehouse management

Process outgoing shipments (record and control items, quantities, dates, times, destinations, etc.)

Returns management

Investigate and identify defective products, handle returns, and maintain return history

Product management

Management of linking the number of items to storage locations, review of purchase numbers, and forecasting of orders

Inventory operations

Verification of actual counts and disposition of bad inventory

Inventory management here includes all inventory related to manufacturing and sales. For example, in the manufacturing industry, this includes raw materials such as materials and parts, as well as work in process, finished goods, and packaging materials needed for storage.

Inventory control is to accurately manage and adjust the number and storage location of all goods to ensure that they are in the proper quantity.

Purpose of inventory control

The purpose of inventory management is to maximize profits by optimizing inventory. By accurately identifying the inventory that exists within a company and keeping it at the proper quantity, the company can prevent sales opportunities from being lost due to disposal or shortage of products caused by excess inventory.

The main objectives of inventory control can be summarized as follows

- Realization of profit maximization

- Visualization of all inventories and accurate quantities

- Maintain adequate inventory

- Controlling losses due to excess inventory and shortages

Holding too much inventory creates the risk of bad inventory due to deterioration or out-of-production. If the inventory needs to be disposed of, unnecessary costs will be incurred.

Insufficient inventory can also damage a company’s sales. A shortage of needed goods can lead to a situation in which the company cannot manufacture or sell the goods, resulting in missed sales opportunities.

To eliminate loss and waste and maximize profits, it is important to accurately manage and control inventory to the proper quantity.

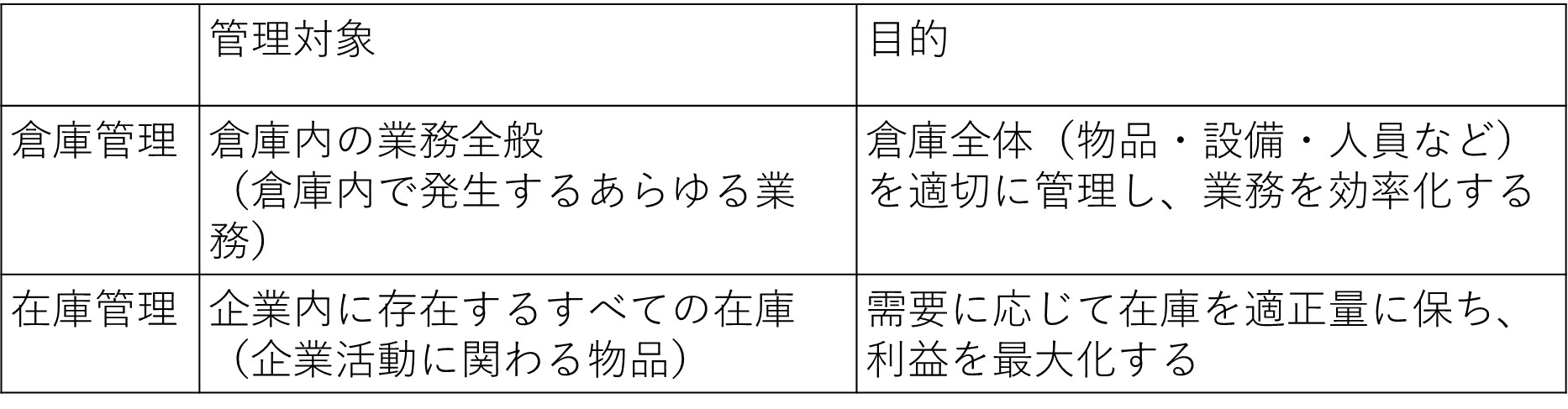

Differences between Warehousing and Inventory Management

Warehousing and inventory management are often confused with each other, but they are different operations. The major difference between the two is the “object to be managed” and the “objective.

First, please see the table summarizing the differences between warehouse management and inventory management.

Warehouse management covers all warehouse operations. By properly managing the goods, equipment, personnel, and on-site operations in the warehouse, we aim to improve operational efficiency and productivity.

Inventory management, on the other hand, covers all inventory that exists within a company. This includes materials brought into the factory, products stored at the distribution center, and goods that have not yet been delivered after being ordered, including inventory in the warehouse.

The objective of inventory management is to maximize profits by maintaining appropriate inventory levels, and emphasis is placed on accurately identifying and controlling the proper amount of inventory.

Thus, although there is some overlap in operations between warehouse management and inventory management, their targets and objectives are different.

WMS" to streamline warehouse management operations

The following section describes the WMS, which is utilized for warehouse management.

WMS stands for “Warehouse Management System,” which in Japanese means “warehouse management system. The system is designed to improve warehouse management efficiency and work quality, and is equipped with various functions such as warehouse receipt/issue management, inventory control, inventory count, form issuance, and label creation.

WMS is being introduced in a wide range of industries, including manufacturing, wholesale, and e-commerce, as a system that provides comprehensive support for warehouse management and on-site operations.

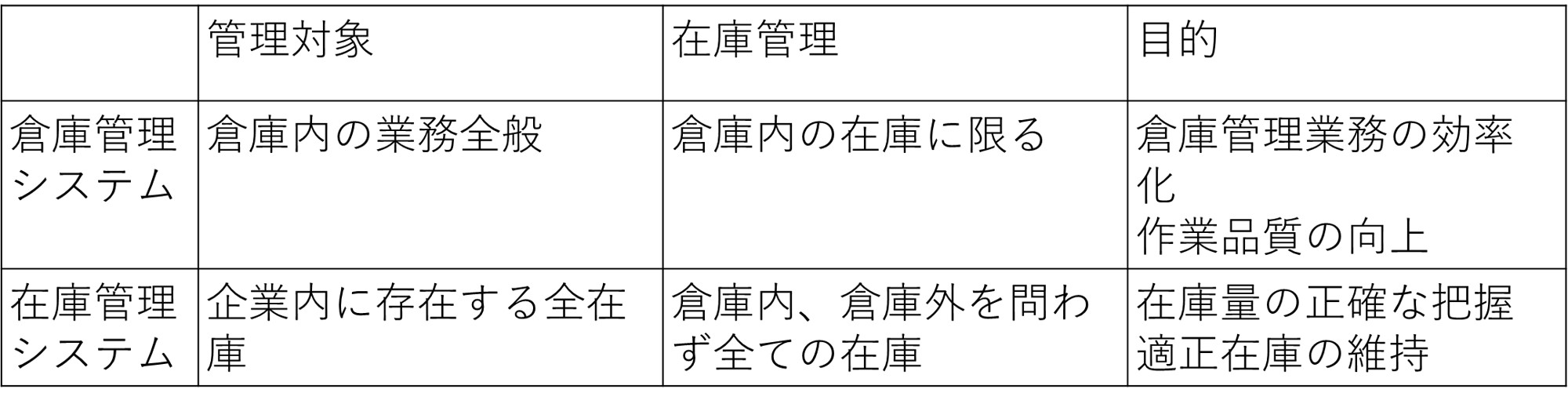

How does it differ from an inventory control system?

Just as warehouse management and inventory management are easily confused, many people find it difficult to tell the difference between a warehouse management system (WMS) and an inventory management system.

Warehouse management systems are designed to improve the efficiency and quality of warehouse management operations. One of the functions included in the system is inventory management, but the target of management is limited to the inventory in the warehouse.

Inventory management systems, on the other hand, are designed to keep track of the entire company’s inventory and maintain it at the proper quantity. All inventories related to corporate activities, both inside and outside the warehouse, are subject to management.

The differences between warehouse management systems and inventory management systems are summarized below.

Basic functions of WMS

Here are the basic functions included in the WMS.

warehouse management

This function records and manages goods that arrive in the warehouse. The date, time, item, quantity, condition, etc. of incoming goods are listed and managed. By using a handy terminal to inspect incoming goods, checks can be completed quickly.

warehouse management

This function manages and records goods to be shipped from the warehouse. It can manage shipping schedules, create picking lists with location information, and record shipping records.

Inventory Control

This function manages inventory information in a warehouse.

The system can manage detailed information such as items, quantities, storage locations, production dates, and expiration dates. Inventory information is updated in real time, so it is possible to quickly determine where and how much is currently in the warehouse.

Location Management

This function registers and manages the location information of goods. A handy terminal is used to register location information. Since not only item but also lot information is managed, picking and checking operations become more efficient.

inventory control

This function manages and records information related to inventory. In addition to the inventory history management function, some of them are equipped with functions to support inventory operations. Examples include managing the inventory workflow, inventory variance lists, and inventory reports.

Returned Goods Management

This function manages and records return information. You can check the details of past return history. A return list can be created based on information such as production date and expiration date. You can also check whether, when, and where items were actually returned.

Form and label issuance

This function creates and issues forms and labels required for various warehouse operations. Specifically, the following items can be issued

- label

- invoice

- Packing List

- statement of delivery

- receipt

- work instructions

- picking list

Easy-to-use forms and labels can be issued, making receiving, shipping, and receiving operations and goods management more efficient.

WMSs are equipped with a variety of functions in addition to those introduced so far. Since the details of functions vary from service to service, it is important to choose the one that best suits your company after careful comparison and consideration.

▼The detailed features of the WMS are explained in detail in the following articles

What is WMS (Warehouse Management System), the key to logistics efficiency?

Advantages of implementing a WMS

A WMS solves a variety of warehousing challenges, and the main benefits of implementing a WMS are as follows

- Automated warehouse operations

- We can make it more efficient.

- Reduce human error.

- Check information in real time

- Shareable.

- Instant identification of where goods are stored.

- Cost savings

Let’s take a closer look.

Warehouse operations can be automated and streamlined.

A WMS streamlines warehouse operations by using a barcode reader or other handheld terminal to perform tasks in the warehouse. By simply holding the terminal over the goods, the information is read and automatically stored in a database, greatly increasing the speed of operations.

Handy terminals can replace the manual inspection, filling out warehouse receipts and dispatch slips, and visual verification that used to be done manually. This will lead to a reduction in labor costs, as work can be completed in a shorter time.

Human error can be reduced

The introduction of WMS can reduce human error. For example, when receiving, shipping, or inspecting goods, barcodes are read by a handy terminal to obtain information, thus eliminating human errors such as miscounting or omissions.In addition, if there is a mistake in the work method, the system alerts the user with an error sound or other warning, reducing the risk of missing a mistake.

Real-time information can be checked and shared.

Another major advantage is that all information in the warehouse can be checked and shared in real time, and since the WMS immediately reflects incoming and outgoing data, there is no discrepancy between the inventory in the system and the actual inventory. Not only inventory quantities, but also changes in storage locations are recorded at the same time.

It can visualize the current inventory count in the warehouse, the status of goods received and ordered, and even the status of work in the field.

Instant identification of where goods are stored.

The WMS can also manage storage locations in addition to item information. Since all inventory information in the warehouse is managed centrally in the WMS, you can immediately check “where” and “how many” items are stored in the warehouse by simply opening the screen.

Picking and inventory operations are greatly streamlined by eliminating the need to search for necessary items in a large warehouse.

Cost savings

The use of a WMS can lead to cost savings if various operations in the warehouse are made more efficient. Operations that used to be performed manually or visually can now be digitized, which can be expected to increase work efficiency and productivity.

Labor costs can be reduced by shortening work hours and optimizing staffing.

▼ The advantages and disadvantages of WMS are explained in detail in the following article

A management system that solves the problems of logistics warehouses [What are the advantages and disadvantages of WMS implementation?

Contact Taiyo Kogyo for consultation regarding warehouse expansion.

Many companies are reviewing their warehouse operations and optimizing their business processes as they grow and expand their operations. The introduction of a WMS can be very effective for such companies.

If you are considering adding or relocating a warehouse in conjunction with the introduction of a system, we recommend the use of a “tent warehouse. Tent warehouses are constructed with steel frames and sheet-membrane materials stretched over the steel frames, and are characterized by sufficient durability, low cost, and a short construction period. They can also be used for sudden expansion or relocation.

Since its establishment, Taiyo Kogyo has been committed to the performance and quality of membrane materials, and we offer a variety of tent warehouses that take advantage of our technological expertise. If you are interested in our tent warehouses, please visit our website.

▼ Click here to request product information, case studies, and brochures from Taiyo Kogyo Co.

https://www.tentsouko.com/

Understand the difference between warehouse management and inventory management before utilizing WMS.

This article has provided an overview of the differences between warehouse management and inventory management, as well as an overview of WMS. Warehouse management and inventory control tend to be confused with each other, since warehouse management includes the task of managing inventory in a warehouse. In order to implement the most appropriate WMS for your company and to ensure smooth day-to-day operations, it is important to accurately understand the differences between the two.

への

Contact us

What you need to know when building a warehouse

We packed it all in.

Clues to solving the 2024 problem

I want to build a warehouse in an economical way.

Which type of warehouse should we build?

I want to learn the basics of warehouse construction anyway.

I'm concerned about the 2024 problem, but I don't know what to do about it.

Related Articles

- TOP>

- Taiyo Kogyo Column>

- Before implementing a WMS! Know the difference between warehouse management and inventory management|Explanation of the main functions, roles, and benefits of WMS.