Taiyo Kogyo Column

“Creating a pleasant working environment by eliminating unreasonableness, waste, and unevenness at logistics sites.”

2021.10.27

Interest in environmental issues, such as ESG investments and SDGs, has been growing more and more with each passing year.

Against this backdrop, running flexible container bags are once again attracting attention as an initiative to reduce environmental impact. In this article, we interviewed Ms. Emi Murano, Group Leader, Logistics Group, Operations Department, Prime Polymer Co.

Upcycle flexible container bags, which have a longer service life than marine containers

Prime Polymer Co., Ltd. Business Department Emi Murano

It's a nice bag.

These bags are made by upcycling used flexible container bags that have reached the end of their useful life. We recently exhibited and sold these bags at an exhibition* organized by Molp, a volunteer group of Mitsui Chemicals, our parent company. People call out to me on the street when they see me carrying this bag. It seems that the letters on them catch their eyes. With natural disasters on the increase and environmental issues becoming more pressing, it seems to be in tune with the times.

This bag is made of recycled EVA raw material. We believe that it is necessary for the sustainability of society not only to sell plastic raw materials but also to think about the end of the product after it is sold.

In fact, at Molp’s suggestion, Mitsui Chemicals, Prime Polymer, and Taiyo Kogyo have been measuring the environmental impact of returnable flexible containers using LCA. Collaboration between the parties making and using flexible container bags has made it possible to quantify the environmental impact.

Molp Café: https://jp.mitsuichemicals.com/jp/release/2021/2021_0628.htm

By upcycling plastic flexible container bags into bags after many years of use, you are using them even longer and reducing environmental impact. How long are the flexible container bags used?

Each company may stipulate the service life, but we have determined it to be 15 years based on various tests. The service life of steel marine containers, which are similarly used in logistics, is 7-8 years, which means that they can be used for a longer period of time than that.

You can use them longer than ocean containers! I made it too sturdy (laughs).

Running flexible container bag for carrying resin

Flexible container bags that increase logistics efficiency while reducing environmental impact

How long has our running flexible container bag, which is the material used for this bag, been in use at your company?

We have been using these bags for many years since the inception of Prime Polymer. Before the introduction of running flexible container bags, 25 kg paper bags, similar to rice bags, were mainly used, and they were carried by people. However, with the birth of the flexible container bag, it became possible to use machines to load about 1 ton of material at a time, which led to the automation of the process.

With running flexible container bags, since they are recirculating, they reduce waste and environmental impact, and also reduce costs by circulating resources.

It also contributes to more efficient logistics compared to one-way flexible container bags. Japan is a small country with many compact warehouses, so there is a demand for efficient storage. One-way flexible container bags are not stable when stacked because they have an inner bag that does not allow air to escape. One-way flexible container bags can only be stacked two layers, but the square running flexible container bags we use can be stacked four layers, twice as many. We can store materials efficiently not only in our factory, but also in our sales warehouse and in the factories of our customers.

Partners who make proposals based on data and experience that cannot be seen by shippers alone.

Not only do we use running flexible container bags as packaging material, but we also ask that the bags be managed.

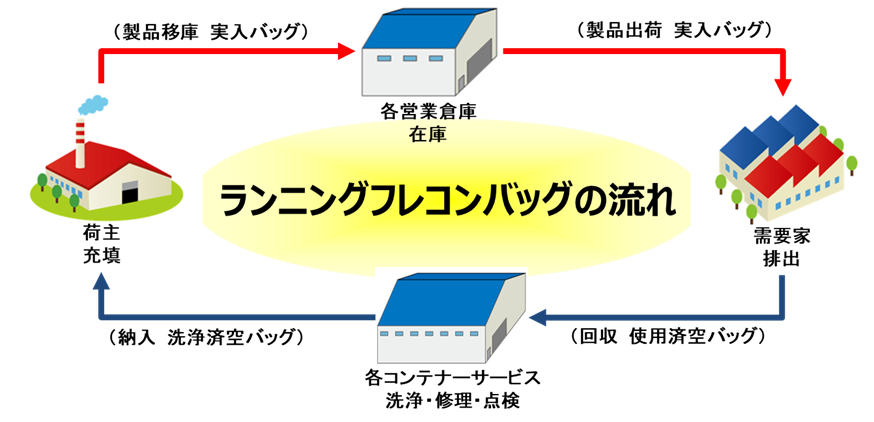

Running flexible container bags are

- Filling contents

- Transport to consumer (customer)

- Discharge at customer

- Collect empty bags

- Transport to container service

- Cleaning, inspection and maintenance

- Returned to prime polymer plant…

The bags are used many times in this cycle, and Taiyo Kogyo manages where and how many flexible container bags are in this cycle. The appeal of this running flexible container bag is that everything is managed from the time it is manufactured to the end of its life. Logistics is a process where the companies in charge of each process are separated, with packaging material manufacturers like Taiyo Kogyo in charge of the production of packaging materials, logistics companies in charge of distribution, and manufacturers in charge of the input of contents, etc. This often leads to a breakdown in information. By having the company manage the entire process in a consistent manner, the company can make use of areas that we, the shipper, cannot understand on our own and the knowledge of its experts to make suggestions for improvement in both the operational and manufacturing aspects of the process.

As we have been partners for many years, our circumstances and our ability to make proposals have been passed down from generation to generation, even as the people in charge change. We feel that this is a sustainable scheme where we can mutually grow as partners.

Our sales people often express that they can focus on their core business. We believe that the management is left to Taiyo Kogyo and the people in charge can focus on their core business.

Yes, I do. Before I was asked to manage the company, I was in charge of collecting flexible container bags and pallets. I was groping my way through it, sticking to the site day after day to manage it. If there are not enough flexible container bags, the contents cannot be filled, and if they cannot be filled, the plant’s production stops, resulting in enormous damage. When we ran out of running flexible container bags, we had to cope by substituting one-way flexible containers and paper bags, but now we can leave it all to you, and it has been a great help.

Taiyo Kogyo Sales Representative Noriyuki Miyamoto

Aiming for a pleasant work environment by eliminating unreasonableness, waste, and unevenness in the workplace.

Please tell us what you are currently working on for the future of the logistics industry.

There is concern about a shortage of human resources throughout Japanese society. Although the current focus is on the driver shortage, we believe that it will become increasingly difficult to secure on-site workers in the future.

I myself have been involved in the logistics industry for 30 years since I joined the company and started my career in the field. I have seen what kind of work is being done in the field on hot days in mid-summer and cold days in mid-winter. Since I have seen such workplaces, I always think about “eliminating muri (unreasonableness), muda (waste), and mura (unevenness). The people onsite may indeed be doing that work, but I believe that it is the shipper’s mission to consider how that work can be done more efficiently, easily, and pleasantly.

Logistics involves a lot of people, and there are many areas that are not mechanized. This is not because technology is lagging behind, but because the industry has been relying on people because they can handle it; even a small movement of a one-ton unit requires forklift operation. In the future, we need to think of ways to automate handling in this area through reforms in the way we work.

Since last year, our company has been testing a system that includes vehicle reservation and a handy terminal. We would like to use the handy terminals not only for product traceability, such as shipping inspections, but also to be able to link items that contribute to products, such as packaging materials, and we are testing this with the cooperation of Taiyo Kogyo.

From Japan! Realizing recycling-oriented logistics around the world

Looking ahead to the future of the logistics industry, what are your requirements for the "flexible container bag of the future"?

We considered three steps: short term, medium term, and long term.

First, from a short-term perspective, it is the ease of handling existing running flexible container bags that are collected and used repeatedly. We were recently told that one bag made of EVA weighs 13 kg* and is lighter, but even if it is light as a flexible container bag, it is still heavy when replaced in daily life. (*Previously, they were made of PVC and weighed about 20 kg.) We also feel that if they could be folded more compactly, they would be easier to carry, the handling load would be reduced, and collection would be simpler. Cargo handling is no longer the role of the driver, but is becoming the role of the shipper. In the future, it will be necessary to create an environment where the elderly and women can be engaged in any type of work, so we need a system that does not require heavy labor when people work on it. In order to expand the use of running flexible container bags in the future, we feel that it is necessary to develop running flexible container bags that retain the existing durability, service life, and quality, but with other considerations for the environment and people.

The more compact and easy to work with, the easier the cleaning part of the container service on our side will be.

As a next step, I would like to see common bags as a way to establish a domestic recycling system. I mentioned earlier about circulation, but only within our own group’s domestic factories. Taking pallets as a similar example, there are systems such as rental pallets that can be shared by other companies. This kind of sharing mechanism reduces the overall quantity. If the number of pallets to be held is reduced, it may be acceptable to shorten the service life of pallets a little, and so on.

In order to create a circular flow of common bags used nationwide, collection, reuse, and recycling after use, it is necessary to involve other companies in the same industry, and only manufacturers can do this. This is because users are only interested in their own companies and do not know what size and shape their neighbors are using. The manufacturer specifies specifications, such as the 14 common pallet sizes, and the user can then say, “This is the common specification! and “We have no choice but to conform to these specifications! If the manufacturer specifies such a situation, we users will be able to choose to use common bags.

It would be nice if Taiyo Kogyo could create a recycling cycle in which each company takes a common thread and produces common bags, cleans them, and recycles the used ones, and if users can get on that cycle, they can use environmentally friendly packaging materials, and if they are just participating in this project, they can say “environmentally friendly” without having to conduct surveys at each company. It would be nice if the project provides added value so that users can proudly say, “We are environmentally conscious,” even if they do not conduct their own surveys.

Finally, this may be a distant future, but I dream of a world where running flexible container bag logistics systems can be used worldwide. Currently, running flexible container bags are only operated domestically, but there is talk that flexible container bags can be recycled worldwide. From the perspective of environmental impact, it is possible to lighten the environmental burden by using the same product over and over again, rather than reusing the resource back into a resource. For this reason, I would like to see the creation of a running flexible container bag that can be used globally, just like marine containers. The difficulty is that there is no collection scheme, and it is not possible to ride them out, but I think it would be good to have a commuter flexible container bag, such as from Southeast Asia to Japan and the U.S. Our company often carries resin, so I can’t really imagine what else could be put in a flexible container bag, but…, rice, wheat, coffee beans, etc.?

Right. For materials, there is a lot of lime and cement, and for food, there is a lot of starch and cornstarch.

I am thinking in an amateurish way, that it might be better to use a thin film inside the package so that only the surrounding area needs to be cleaned, or to design a common flexible container bag by working backwards to determine what shape would be best for a maximum loading capacity in a marine container. In any case, I think the flexible container bag circulation system is a system that can be sung as “from Japan,” and I feel that we would like to expand it to the world.

He spoke extensively about on-site operations and the global expansion of flexible container bags.

I hope we can continue to work together as good partners to make the industry more prosperous in the future. Thank you very much!

Inquiries about Container Bags

Logistics Business Headquarters

〒154-0001

2-33-16 Ikejiri, Setagaya-ku, Tokyo

〒532-0012

4-8-4, Kigawahigashi, Yodogawa-ku, Osaka City

Contact us by phone

Tokyo: 03-3714-3133

Osaka: 06-6306-3084

Logistics Businessへの

Contact us

Related Articles

- TOP>

- Taiyo Kogyo Column>

- “Creating a pleasant working environment by eliminating unreasonableness, waste, and unevenness at logistics sites.”