Taiyo Kogyo Column

Tents required for soil improvement work │ Proper understanding of their types and situations of use

2020.09.09

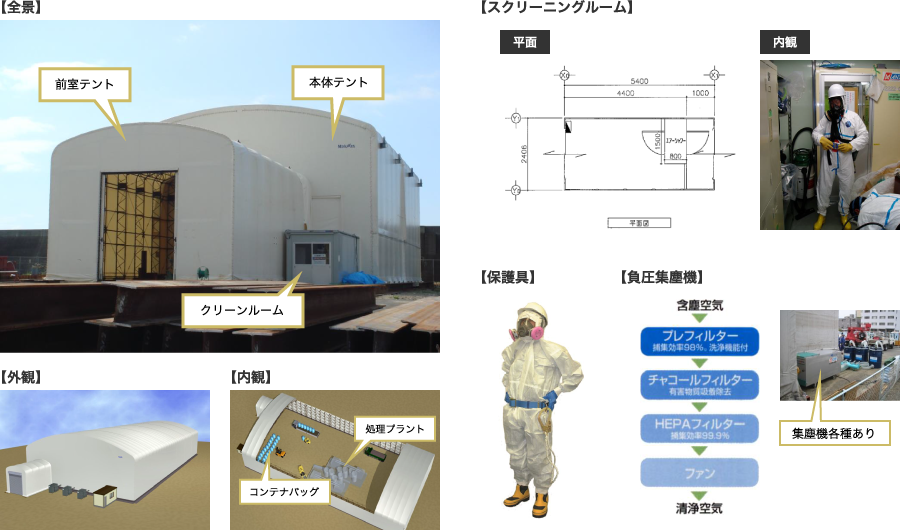

Improvement work on contaminated soil requires a variety of equipment, depending on the contaminants to be handled and the method to be used. One of the largest and most legally required pieces of equipment is the soil improvement tent.

This article will introduce the types of tents available for remediation of contaminated soil and the situations in which they can be used, broken down by case. Please use the information in this article to help you determine what tents exist and which are appropriate for various soil remediation sites.

Tent Warehouseへの

Contact us

What you need to know when building a warehouse

We packed it all in.

Clues to solving the 2024 problem

Recommended for

I don't know where to start in building a warehouse.

I want to build a warehouse in an economical way.

Which type of warehouse should we build?

I want to learn the basics of warehouse construction anyway.

I'm concerned about the 2024 problem, but I don't know what to do about it.

Related Articles

- TOP>

- Taiyo Kogyo Column>

- Tents required for soil improvement work │ Proper understanding of their types and situations of use