Taiyo Kogyo Column

Necessity of installing anti-scattering tents at contaminated soil remediation construction sites.

2020.09.09

When performing contaminated soil response work, some sites require tents for a variety of reasons. There are diverse types of tents for different uses, and the right type of tent must be installed.

This article describes anti-scattering tents, which are required at sites where scattering of contaminants may occur. In what situations are shatterproof tents needed? What kind of tent is needed and what features should we look for?

For those involved in the subject field, please refer to the contents of this article.

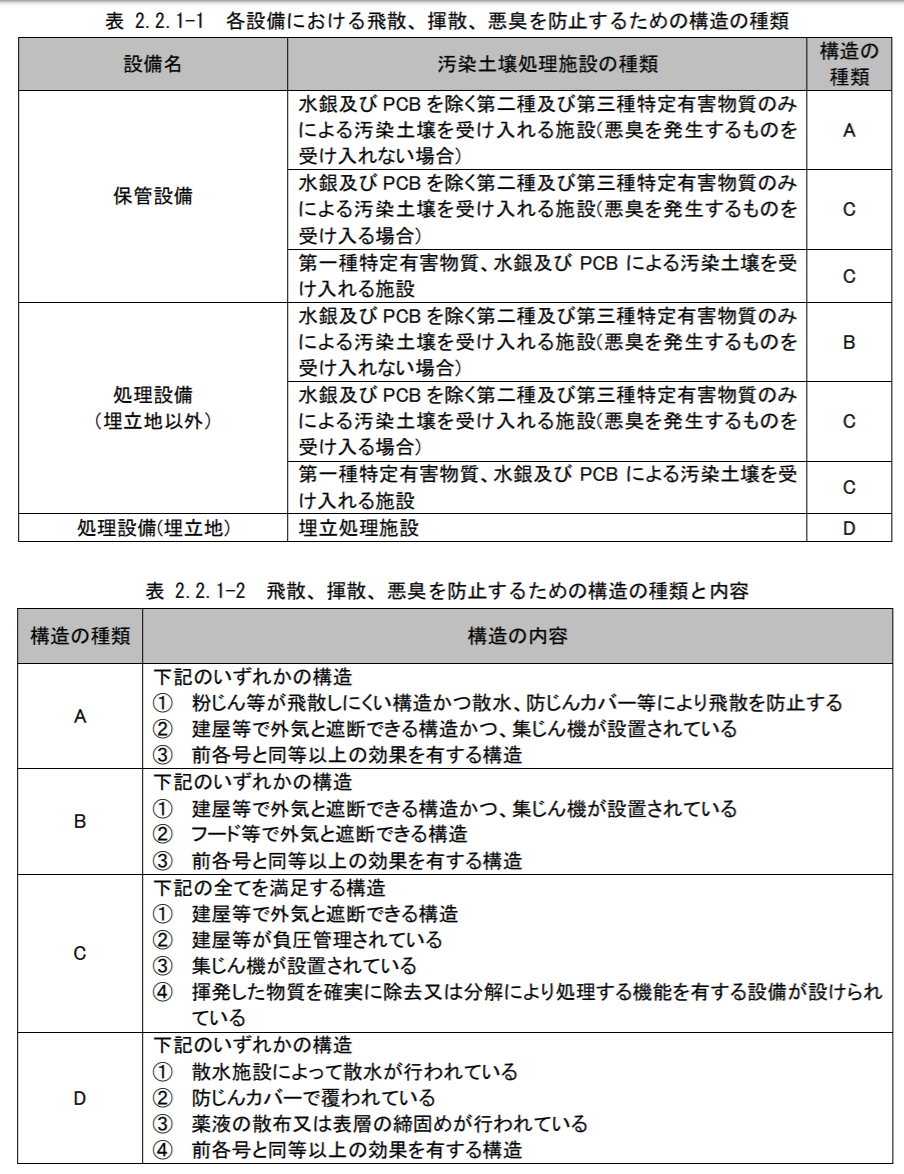

(Source: Ministry of the Environment, Technical Considerations for Permit Examination of Contaminated Soil Treatment Business)

In order to properly implement the prevention of contaminated soil dispersal, the site environment must be created with appropriate equipment. The equipment that can be utilized for this purpose is a shatterproof tent. Compared to general construction, tents offer a high degree of versatility and convenience, as they can be used for outdoor work or indoors, such as in treatment facilities. Here, we take as an example a scattering-prevention tent for soil contamination countermeasures by Taiyo Kogyo Corporation, which has been involved in membrane structures for about 100 years.

Taiyo Kogyo’s tents can be utilized in a variety of sites, as we manufacture membrane structures with free design and high design quality, taking into consideration the purpose and the environment. The scattering-prevention tents are the culmination of the company’s know-how and are equipped with optimal functions for preventing contaminants from scattering into the surrounding area. The main features are as follows

Structure for easy moving and relocation

The roof unit can be moved by crane or winch to accommodate large areas. The structure also facilitates relocation of large-span facilities (W15 to 30 meters), thus reducing costs.

Extensive lineup to protect the work environment

The facility can also accommodate the necessary equipment to prevent contaminants from being carried outside, such as a tent in the front room for temporary waiting areas for work vehicles, screening rooms, negative pressure dust collectors, etc. Screening rooms are equipped with air showers and changing rooms, etc. to prevent dispersal of contamination and contamination to workers and ensure safe management of the work environment. Negative-pressure dust collectors can discharge air containing dust as clean air through multiple high-performance filters.

Sizes can be accommodated on request

There are four types of frontage: 15m, 20m, 25m, and 30m, and the depth is available in 2m increments to meet your needs.

Pillarless space ideal for indoor work

The bolt-on frame type structure, which does not use columns, makes it possible to maximize area and create space for flexible layout. In addition, assembly and disassembly can be performed in a short period of time using a large crane.

Tent Warehouseへの

Contact us

What you need to know when building a warehouse

We packed it all in.

Clues to solving the 2024 problem

Recommended for

I don't know where to start in building a warehouse.

I want to build a warehouse in an economical way.

Which type of warehouse should we build?

I want to learn the basics of warehouse construction anyway.

I'm concerned about the 2024 problem, but I don't know what to do about it.

Related Articles

- TOP>

- Taiyo Kogyo Column>

- Necessity of installing anti-scattering tents at contaminated soil remediation construction sites.