Taiyo Kogyo Column

What facilities are legally required for contaminated soil treatment operations? Requirements and types of tents and temporary roofs

2020.09.09

In Japan, soil contamination associated with industrial development has become a social issue since the Meiji era. The problem of soil contamination by hazardous substances is spreading in various areas around us, from agricultural land to urban areas, and various measures have been taken to date.

Now that the actual condition of contaminated soil has been clarified, methods have been established for the treatment of contaminated soil. Since hazardous substances are handled, laws and regulations with various standards have been established to ensure strict handling of these substances, and compliance with these rules is required.

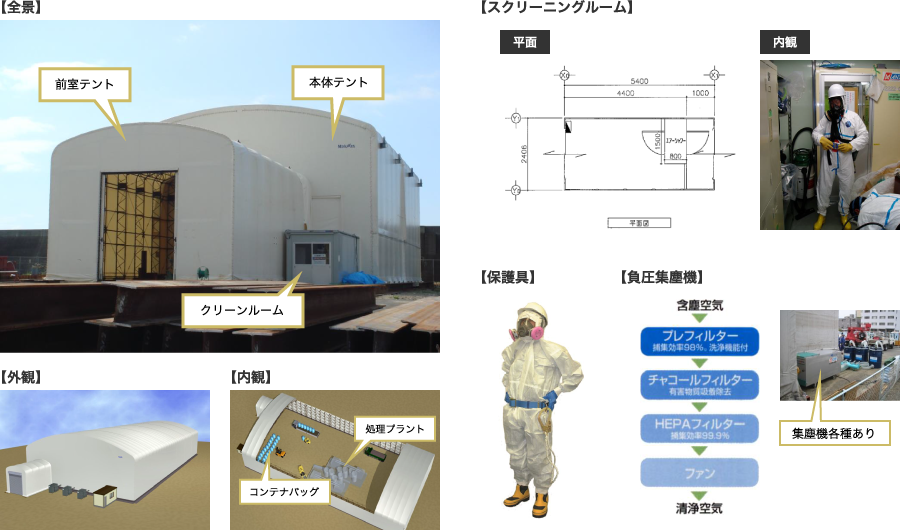

This article describes the requirements for contaminated soil treatment operations and the equipment used to perform them. We will also introduce the specifics of tents and temporary roofs, which are the most important of these facilities.

Please use this information as a reference when preparing for contaminated soil treatment.

Tent Warehouseへの

Contact us

What you need to know when building a warehouse

We packed it all in.

Clues to solving the 2024 problem

Recommended for

I don't know where to start in building a warehouse.

I want to build a warehouse in an economical way.

Which type of warehouse should we build?

I want to learn the basics of warehouse construction anyway.

I'm concerned about the 2024 problem, but I don't know what to do about it.

Related Articles

- TOP>

- Taiyo Kogyo Column>

- What facilities are legally required for contaminated soil treatment operations? Requirements and types of tents and temporary roofs