Taiyo Kogyo Column

Warehouse Heat Stroke Prevention! It’s not too late to make your logistics warehouse or factory more comfortable in the summer

2019.09.19

Recent summers have been hot and humid, making for a harsh outdoor working environment. Even air-conditioned indoor spaces can feel hot, so the temperatures inside warehouses, where air conditioning does not work and ventilation is poor, can be very difficult.

It would be nice if summer heat were only uncomfortable, but it involves people working in the warehouse. If it is too hot, work efficiency is reduced, and there is a risk of heat stroke and other health hazards to employees. High temperatures are also not a good storage environment for stored goods. It also leads to condensation and unpleasant odors.

Are warehouses and factories properly protected against heat? This article introduces heat protection in warehouses and factories. With the right heat protection measures, you can be sure to improve both work efficiency and health.

Japanese summers are getting hotter and longer.

Gone are the days when we could say, “It’s normal for summer to be hot” or “It’s so hot that it’s sloppy to get tired of it. According to the Japan Meteorological Agency, the average summer temperature in Japan has become hotter by 1.5°C for the highest temperature and 2.7°C for the lowest temperature over the past 100 years.

Does 1.5°C sound like no big deal? It is only an average value, so if you imagine your own average body temperature (normal temperature) rising by 1.5°C, you will understand the magnitude of the impact.

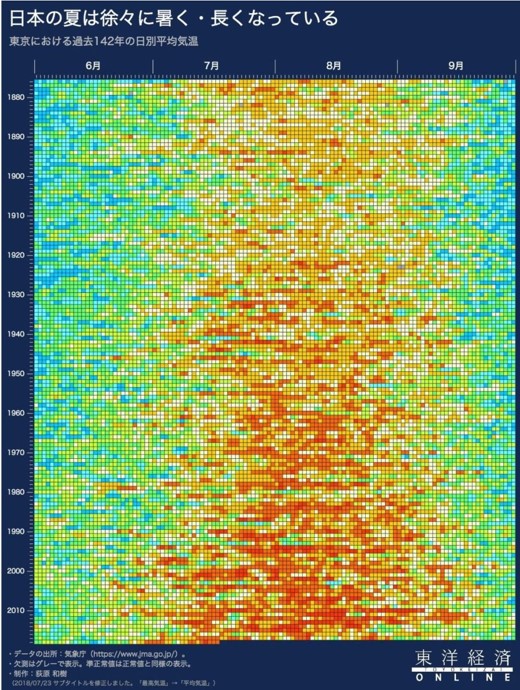

The number of days with high temperatures is gradually increasing. Data from the Japan Meteorological Agency is easy to understand (see figure below).

(Source: Japan Meteorological Agency (https://www.jma.go.jp/)

The lower the graph, the more recent the trend. The red areas indicate hotter days. You can see that the number of hot days is increasing. Japanese summers are getting hotter and hotter, and for longer periods of time.

More than 1,500 deaths annually due to heat stroke

Heat stroke is becoming more prevalent as the weather gets hotter. According to statistics from the Ministry of Health, Labor and Welfare, more than 1,500 people died from heat stroke in 2008.

In recent years, the number of heat stroke casualties has been in the 400-500 range, but has not exceeded 1,000 in the past 10 years, with the exception of 2008.

Furthermore, statistics including work-related illnesses requiring time off from work reported more than double the number in 2008 compared to the previous year. Similarly, the number of deaths due to heat stroke in the workplace is also double that of last year. Thus, the need for countermeasures against heat stroke at work is becoming more urgent than ever.

Is it 40 degrees Celsius inside a warehouse? What causes heat in warehouses and factories?

So what exactly is the temperature inside a warehouse? We will explain by comparing it to the appropriate temperature.

In a warehouse or factory without air conditioning in mid-summer, the maximum indoor temperature can reach 40-45°C. You can measure this in your own warehouse by installing a thermometer. Even without specialized knowledge, one can imagine that the level is dangerous to the human body.

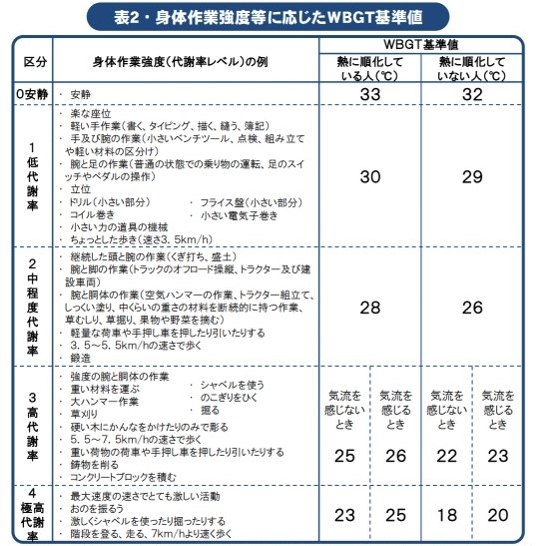

The Ministry of Health, Labour and Welfare (MHLW) has established the ” WBGT” (heat standard value ) as a reference value for the appropriate temperature for operations. according to WBGT, the upper limit of the appropriate temperature for warehouse operations is 26-30℃.

Compared to the actual situation, there is actually a discrepancy of 10°C to 20°C. It is clear that the warehouse requires a very large scale heat control system.

The appropriate temperature varies depending on the work intensity (Source: Ministry of Health, Labor and Welfare)

*A person who is not acclimatized to the heat refers to a person who has not been exposed to heat every day during the week prior to work.

High humidity is also a factor, creating a hot and humid environment. Unlike outside, there is no wind inside the warehouse, making it difficult for sweat to evaporate and heat inside the body to escape.

So why does it get so hot in warehouses?

In some cases there is no air conditioning in the first place, but in many cases the cause is structural.

The main causes of heat in warehouses and factories are roofs and walls. Warehouses built over a large area and on large lots can heat up to nearly 70°C (158°F) when the roof and walls are exposed to direct sunlight.

In particular, the roofs and walls of warehouses tend to be thin and not double-layered, etc., and are directly connected to the interior. Therefore, they have structural characteristics that allow heat accumulated in the components to accumulate indoors as it is.

The heat buildup in these warehouses becomes hotter and hotter because there are no partitions and the high ceilings make it difficult for the air conditioning to work.

Related Documents: Download a 5-minute comparison of warehouse construction

Heat Protection in Warehouses and Factories

So how can we improve people’s work efficiency and protect their health in such a hot warehouse? Here are some typical heat-related measures.

Awareness and hydration

What is most important is that those who work there and those who manage it have the proper knowledge to start taking measures. First of all, be aware that “it is a dangerously hot environment in a warehouse.

In addition, those in a management position should be more careful to ensure that adequate breaks and hydration are taken.

air conditioner

Air-conditioned clothes are work clothes with a built-in fan and a mechanism to circulate air inside the garment. It dries sweat instantly and is effective in solving problems such as heat rash and skin problems. A variety of products exist, including those that use functional materials to enhance moisture permeability. Although the price of small fans is high, they have become easier to purchase in recent years.

However, in environments where it gets wet with water or where there is dust/dust, the small fan will be drawn in with the outside air, which may cause malfunction. In addition, the inner lining will also become dirty, so care should be taken.

(Source: Askul)

spot cooler

Spot coolers are an effective way to lower temperatures in warehouses where air conditioning is difficult to install or work. If they can be installed in specific work spaces or where people pass by, they can be expected to have a significant cooling effect.

They are expensive to purchase, large in size, take up a lot of space, and require consideration of heat exhaust. It also requires the hassle of supplying and draining water at regular daily intervals and inspecting the Freon system. In addition, since it is not possible to cool an entire warehouse, it is limited to “spot” use only.

Large fans and ceiling fans

Although not as effective as spot coolers, large fans are inexpensive, take up less space, and do not need to worry about heat exhaust. However, it may be difficult to install them in warehouses that handle lightweight items, precision parts, and hygiene-conscious products.

Ceiling fans are fans that are installed near the ceiling. Rather than directly blowing air to cool the room, it circulates the air throughout the room, which is expected to lower the temperature. As a secondary effect, it also suppresses condensation and reduces unpleasant odors. Installation requires work that requires an elevating work vehicle, and is somewhat difficult after installation of machinery and equipment.

Roof sprinklers

Roof sprinklers were born from the idea that if the roof is caused by heat, then the roof can be cooled. Roof sprinklers are installed to sprinkle water on the roof, and the vaporization heat of the sprinkled water lowers the temperature of the roof. It is a natural and environmentally friendly solution.

It can be quite effective, but the construction work will be of a certain scale and the water bill will be a running cost. In addition, the strain on the roofing material may lead to deterioration.

Thermal barrier paints and sheets

Similarly, measures to be taken on roofs include paints and sheets with heat shielding effects. While it can be expected to have a certain effect, the concern is that it needs to be replaced periodically and is quite costly considering the area of the factory roof.

Related Documents: Download a 5-minute comparison of warehouse construction

Let's address the root cause of heat in warehouses.

While the above measures against heat are effective, they are not necessarily fundamental solutions, as they all have a first-aid aspect or are insufficient in some cases as stand-alone measures. There is room for review from the structural aspect as well.

We therefore recommend “tent warehouses” with a membrane structure. Tent warehouses can keep the temperature inside the warehouse from rising, even in the summer, due to the properties of the materials used.

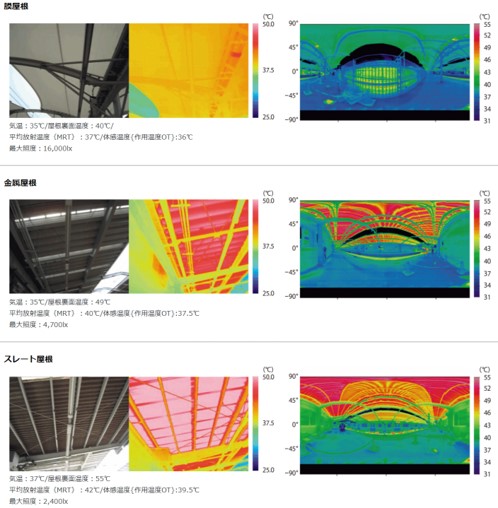

For example, white membrane roofs have a high solar reflectance of more than 75%, which results in a better thermal environment in the space covered by the membrane roof. Comparative measurements of the temperature under the roof (OT) for three types of roofing materials (membrane, metal, and slate) confirmed that the temperature under the membrane roof was 1.5°C lower than that of the metal roof and 3.5°C lower than that of the slate roof.

Temperature comparison of membrane, metal, and straight roofs. It can be seen that membrane roofs are highly effective against heat.

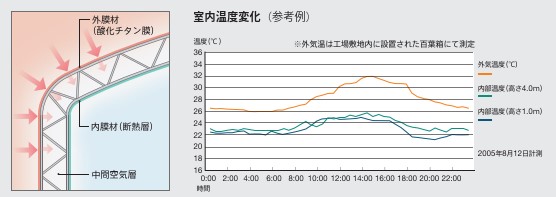

The double-membrane tent warehouse, which utilizes a steel framework, has a proven track record as a cold- and heat-insulated warehouse, allowing for temperature control inside the warehouse.

Godo Shusei Co., Ltd. Shizuoka Prefecture Warehouse (food raw materials)

By using a heat insulating membrane for the interior membrane, the cold and heat retention effects are further improved.

In addition, another feature of tent warehouses using membrane materials is the ability to provide not only temperature but also humidity protection.

Related article, ” What are effective means of ‘moisture control’ in medium-sized warehouses? ”

In addition, since only the roof can be retrofitted with membrane materials, simple construction will allow existing buildings to benefit from this technology.

Related article, ” What is the Best Time to Repair or Replace a Medium-Sized Warehouse Roof? ”

The beauty of tent warehouses is that they offer a high degree of flexibility in terms of layout to improve ventilation, as well as a combination of ventilation fans, air supply vents, and other facilities.

As a measure to improve the environment of warehouses and factories in Japan’s summer, which will continue to get hotter and hotter, why not consider a tent warehouse made of membrane material?

Contact us for more information about tent warehouses and tent factories/workshops.

Tent Warehouseへの

Contact us

What you need to know when building a warehouse

We packed it all in.

Clues to solving the 2024 problem

I want to build a warehouse in an economical way.

Which type of warehouse should we build?

I want to learn the basics of warehouse construction anyway.

I'm concerned about the 2024 problem, but I don't know what to do about it.

Related Articles

- TOP>

- Taiyo Kogyo Column>

- Warehouse Heat Stroke Prevention! It’s not too late to make your logistics warehouse or factory more comfortable in the summer