Taiyo Kogyo Column

The 2024 problem, will we not be able to transport goods? How to achieve “bearer-friendly logistics”?

2021.11.30

Logistics in Japan is now in a critical situation. The labor shortage in the logistics industry, including truck drivers and maritime transport personnel, is expected to be further accelerated in the future due to the decrease in the working-age population. According to the Outline of Comprehensive Logistics Policies (FY2021-FY2025) Summary, labor productivity in the logistics industry has changed little from 2,000 yen/hour in FY15 to 2,025 yen/hour in FY18, which is significantly lower than the labor productivity of all industries of 3,602 yen/hour in FY18. Given that productivity has stagnated over the past few years, the logistics industry is exposed to a critical situation that could result in the inability to transport goods in the future if productivity does not improve in the future and the labor force continues to decline.

Background that things may not be able to be transported.

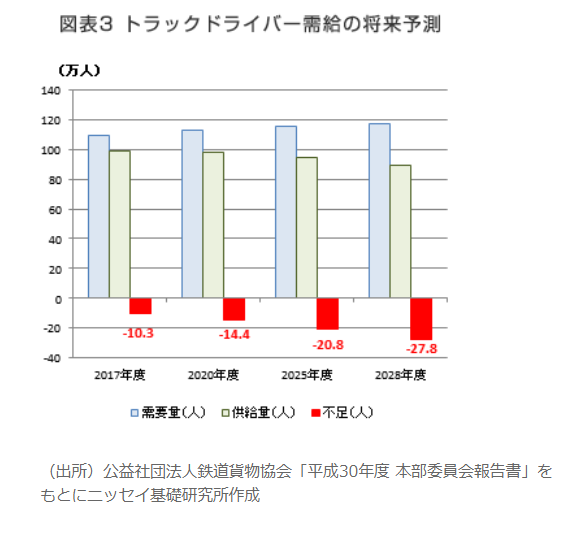

In recent years, the diversification of the needs of shipper operators and consumers has led to the shift to high-frequency, small-lot logistics, and logistics demand is expected to increase even more in the future. On the supply side, on the other hand, according to estimates by the Japan Railway Freight Association, there will be a shortage of 278,000 drivers by FY2028. In the field of logistics, as a matter of practice, drivers are facing a shortage of workers due to heavy labor, long working hours, and low wages resulting from loading and unloading, loading and unloading, and other cargo handling work. In addition, the overtime cap with penalties will be applied from 2024, limiting the amount of work per driver, and there are concerns that the supply of drivers will shrink further due to job turnover caused by lower wages. In order to prepare for a situation in which goods cannot be transported in the future, it is necessary to address the issue of labor shortages by taking an integrated view of commerce and logistics, with the aim of improving the environment for drivers, and by reviewing the assumptions that have been made so far, with the cooperation of all parties involved in origin and destination shippers and logistics.

(in Japanese history)118th Truck Driver Shortage of 278,000 in 10 Years? )

What measures should be taken for sustainable logistics?

In order to maintain a society in which goods are delivered in the future, the Ministry of Land, Infrastructure, Transport and Tourism has identified seven measures to be taken in the future to realize “bearer-friendly logistics” as a labor force measure in the Comprehensive Logistics Program Outline.

Bearer-friendly logistics

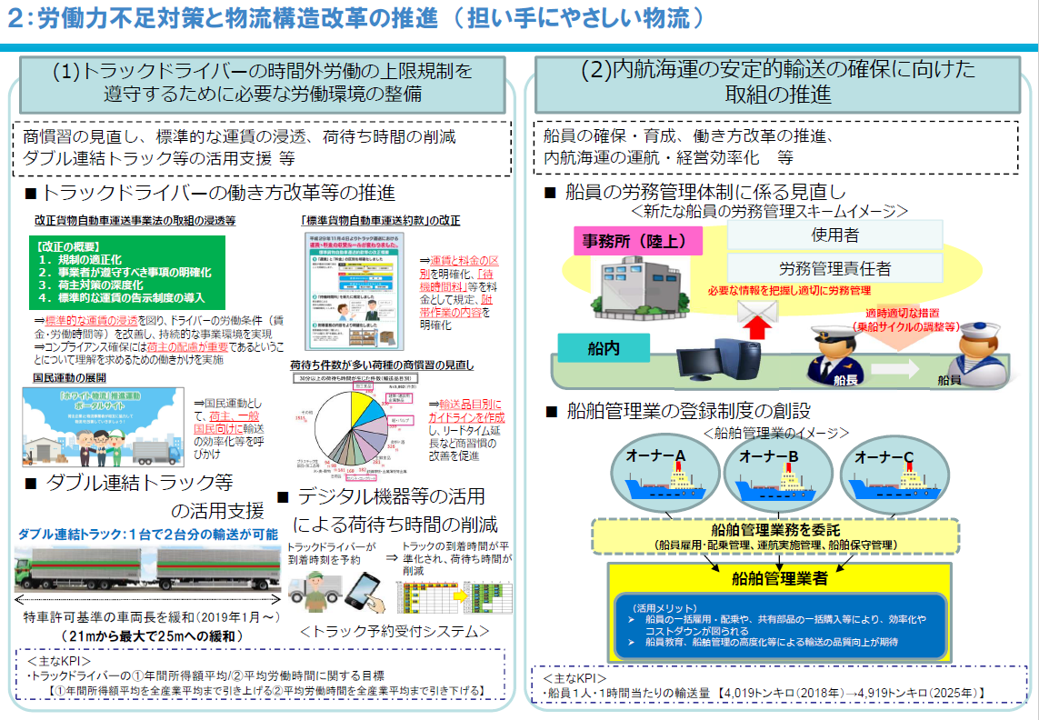

(1) Improvement of the working environment necessary to comply with the overtime work limit for truck drivers

トラック運送業における輸送効率・生産性の向上は急務である一方、これをトラック運送業だけで達成することは困難であり、荷主の理解と協力が不可欠です。

荷主都合による長時間の荷待ち、契約にない附帯作業などが発生しており、これらの時間を減らすことができれば、トラックドライバーが運送に専念できる時間を確保でき、今後の物流の持続可能性は高まります。国として、サプライチェーン全体でリードタイムの延長や最低納品単位の取り決めなど商習慣の見直しを進めるとともに、長時間労働の原因となっている検品作業や荷役の分離の推進などに取り組み、さらなる改善に向け荷主との交渉や働きかけを進めていきます。数値目標として、ドライバーの年間所得平均の向上、平均労働時間を全産業平均まで引き下げることを掲げています。

(2) Promote efforts to ensure stable transportation of coastal shipping

Against the backdrop of a shortage of truck drivers and restrictions on working hours, in order to increase transportation volume through the transportation of modal shift cargo, we aim to improve transportation efficiency and reduce costs through a review related to the labor management system for seafarers and a registration system for ship management services.

(3) Promote innovative efforts to improve labor productivity

With the goal of increasing labor productivity in the logistics industry by 20% from the FY 2018 level by FY 2025, such as by improving truck loading efficiency, the plan includes specific ways to promote digitalization through matching and data sharing systems, further development of joint transfers and deliveries, and promotion of warehouse sharing.

(4) Rationalization of distribution of agricultural, forestry, marine, and food products, etc.

In order to ensure a stable supply of agricultural, forestry, marine, and fishery products and foodstuffs at reasonable prices, we promote the development of joint logistics bases, automation and labor saving, standardization of pallet standards and exteriors, and palletization by establishing rules for pallet operation. The project also promotes the use of pallets by standardizing pallet standards and exteriors, establishing pallet operation rules, etc. All parties involved in production and sales are expected to cooperate with logistics providers and build new relationships to promote rationalization and efficiency.

( https://www.mlit.go.jp/seisakutokatsu/freight/content/001413868.pdf )

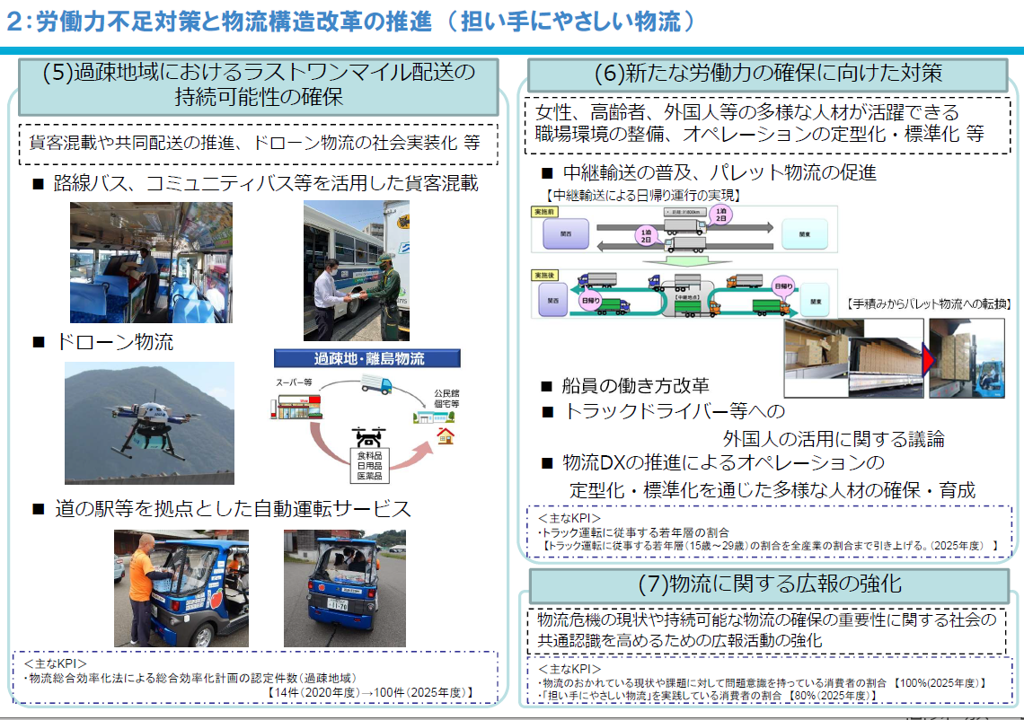

(5) Ensure sustainability of last mile delivery in depopulated areas

In order to maintain logistics networks and functions in depopulated areas, we will develop an environment where people can continue to live in the area through efficient delivery in depopulated areas, including route buses, community buses, and automated and drone logistics based at roadside stations, etc.

(6) Measures to secure new labor force

In order to secure and develop diverse human resources, including women, young people, and the elderly, we will promote reforms in work styles and create a workplace environment in which diverse human resources can play an active role. In securing and fostering diverse human resources, it is also important to consider how operations should be conducted without relying solely on labor practices that emphasize experience and skills, etc. Through the promotion of logistics DX, the standardization and formulation of operations will be promoted by utilizing new technologies such as AI and IoT.

(7) Strengthen public relations regarding logistics

In order to position logistics as a common awareness not only among logistics companies but also among society as a whole, we aim to promote a broad awareness, sharing of issues, and understanding of solutions to the current crisis in logistics, the social value of workers engaged in the logistics business, the overtime limit for truck drivers that will apply from FY2024, and the risk that “goods will not be transported in the future” among general consumers and management. The goal of the project is to raise public awareness of the importance of ensuring sustainable logistics by widely sharing awareness and issues and promoting understanding of solutions to these issues.

What is the bearer-friendly logistics that Taiyo Kogyo is working on?

The main operation that causes inefficiencies and heavy labor in logistics is “cargo handling. Cargo handling work refers to the entire process of handling cargo in the logistics process, starting from unloading cargo from a truck to shipping it out of the warehouse. Taiyo Kogyo’s “slit containers” play a role in saving labor and time in this series of work. Slit containers eliminate the manual loading, unloading, and manual transshipment of cargo, thereby saving labor and time. Slit containers allow forklifts to move and load/unload cargo without using pallets. Compared to pallets, slit containers are lightweight and compactly foldable, can be hung by a forklift for loading and unloading, and can be immediately collected after use. In addition, loading efficiency is not compressed and there are no collection costs.

The biggest challenge in the logistics industry is the labor shortage, and the main cause of this situation is inefficient cargo handling operations. Manual cargo handling is inefficient, hard labor that limits the number of people who can engage in it, and it is dangerous work that can be hazardous to health. The industry as a whole needs to implement fundamental remedial measures as soon as possible to eliminate these problems in order to realize bearer-friendly logistics, secure a new workforce in the logistics industry, and improve labor productivity.

summary

If the past situation in the logistics industry continues, it is inevitable that the current logistics services will become impossible to provide. Now is the time for the entire logistics industry to recognize the current situation in order to realize “bearer-friendly logistics,” and to change into an attractive industry where logistics bearers can work comfortably. To do so, it is necessary to improve the social value of those engaged and to solve the causes of labor shortages. In addition to slit containers, Taiyo Kogyo offers solutions to logistics issues. Please contact us first to discuss your needs with our expert staff who provide total logistics services.

Inquiries about slit containers and logistics material services

Logistics Business Headquarters

2-33-16 Ikejiri, Setagaya-ku, Tokyo 154-0001, Japan

4-8-4 Kigawahigashi, Yodogawa-ku, Osaka 532-0012, Japan

Contact us by phone

Tokyo: 03-3714-3133

Osaka: 06-6306-3084

Related Articles

- TOP>

- Taiyo Kogyo Column>

- The 2024 problem, will we not be able to transport goods? How to achieve “bearer-friendly logistics”?