Taiyo Kogyo Column

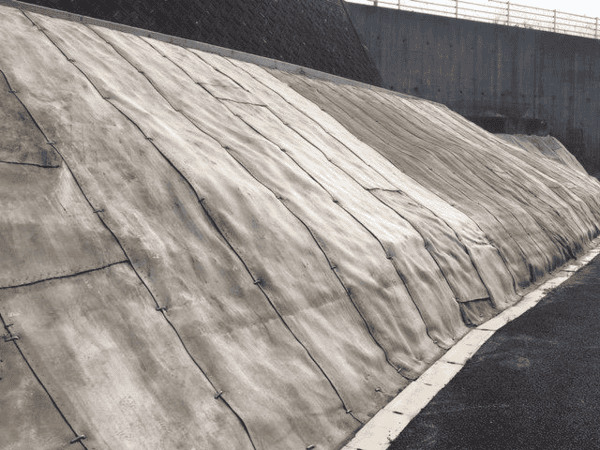

Case Study] Revolutionary weed control along highways and railroads! Membrane that creates a concrete surface just by pouring water on it

When weed control is performed along the sides of highways and railroads, the most common methods are laying weed control sheets and pouring fresh concrete. However, each of these methods has its own major problems. While new solutions are being sought, an epoch-making method that creates a long-lasting concrete surface without the need for heavy machinery, manual labor, and a short construction period has been attracting attention.

We will introduce in detail the examples of weed control alongside highways and railroads.

Challenges in weed control along highways and railroads

Each of the traditional methods of weed control, either by placing weed prevention sheets or by pouring fresh concrete, has significant drawbacks. This will be reviewed and the elements required for a new solution will be defined.

Serious drawbacks of weed control by "laying down weed-blocking sheets

The main drawback of weed control through the installation of weed-blocking sheets is the inefficiency of maintenance costs due to their short lifespan.

The general service life of weed control sheets is from 1 to 5 years. Some sheets claim to last for 10 years, but the reality is that there is a marked difference depending on the environment in which they are used, and this period tends to be shorter on highways and railroads where they are constantly exposed to direct sunlight and wind. Weed prevention sheets are particularly susceptible to deterioration due to ultraviolet rays, and wind pressure from passing vehicles can blow the sheets away while their durability is low, causing increased damage and scattering of sheet fragments.

The low initial cost is attractive because it can be laid for only a few hundred yen per square meter, but it is also difficult to re-lay the sheets frequently. However, frequent re-laying of the sheets increases the maintenance cost.

Serious drawbacks of weed control by "pouring fresh concrete

防草シートの短寿命という欠点を解消するもうひとつのポピュラーな防草の方法が生コンクリートの打設です。コンクリートの寿命は50年程度であるためメンテナンスコストの効率性においては防草シートに勝りますが、一方で別の大きな課題が生じます。

生コンクリートの打設を行うためには現地に専用の重機を搬入し、交通規制をかけて、専門技能を持った作業員が時間をかけて工事をする必要があります。このコストは莫大であり、さらに現場の面積や形状によっては重機の運び入れが困難なことから、そもそも実施可能性が限定的であるというデメリットもあります。

Elements required for weed control methods along highways and rail sides

To summarize the above information, the following elements are required for weed control methods on highways and railroad sides.

- long life

- short construction period

- No need for large heavy equipment

- No need for workers with specialized skills

This is made possible by the “concrete canvas,” which creates a concrete surface simply by pouring water on it.

What is "Concrete Canvas"?

Concrete Canvas is a sheet-like composite material composed of concrete, fabric, and impervious material that cures simply by sprinkling or submerging in water after laying, creating a concrete surface. The thickness ranges from 5 mm to 13 mm, and the thin fabric structure is made by sandwiching specially formulated dry concrete between a 3-dimensional canvas (woven fiber matrix) and PVC sheets. It has the following outstanding features and has attracted significant attention in recent years for use in weed control along highways and railroadsides.

Main features of concrete canvas

Ease of installation: No heavy machinery required, no need for specialized skills, just lay it down and sprinkle water on it.

Related Articles

- TOP>

- Taiyo Kogyo Column>

- Case Study] Revolutionary weed control along highways and railroads! Membrane that creates a concrete surface just by pouring water on it