Taiyo Kogyo Column

Membrane snow shelters are now available! Membranes protect roads in winter.

2020.12.07

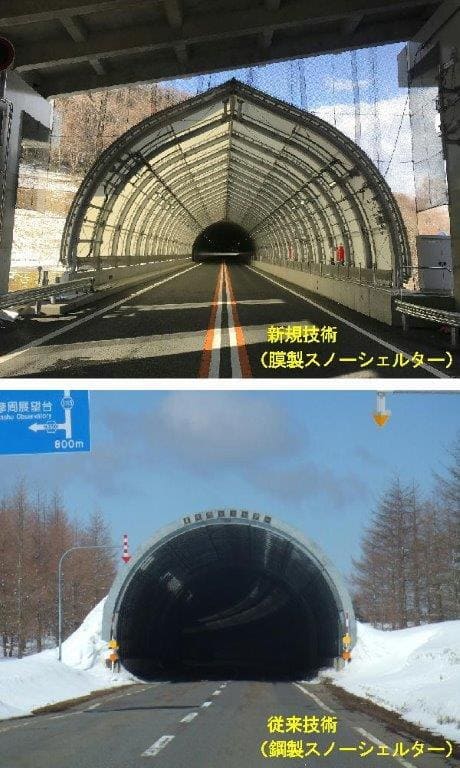

Snow shelters are installed between tunnels in mountainous areas to suppress gusty winds and crosswinds, and in winter, they protect drivers by reducing the effects of road surface icing and snow accumulation. Taiyo Kogyo has applied a membrane structure to these snow shelters. Taking advantage of the features of membranes, such as light weight, brightness, durability, and environmental performance, these shelters protect road safety in winter.

Japan's first membrane snow shelter on a Hokkaido motorway

Snow shelter exterior

Sudden road surface changes are a typical cause of accidents on highways in winter. In mountainous areas with a series of tunnels, there is a tendency for snow to accumulate and freeze on the road surface, causing drivers to brake suddenly and miscalculate their control of the vehicle. Snow shelters are used to protect the safety of roads during the winter. These shelters are roofed over bridges and other structures in continuous tunnels to prevent snow from entering and freezing over, and are highly effective in preventing accidents.

Confirmation of active snow performance equivalent to steel shelter (with SUS plate for sliding snow) Evaluation of salt damage resistance and maintainability

The Yoichi IC to Otaru JCT (total length 23.3 km) of the Goshi Expressway (NEXCO East Japan) in Hokkaido, which opened to traffic in December 2018, has 12 bridges (total length 3.2 km) and 8 tunnels (total length 8.4 km) in the section, with half of the entire section consisting of bridges and tunnels. In addition, the Onnenai Bridge between the first and second Tenjin Tunnels is the first expressway in Japan to be equipped with a membrane snow shelter. The Onnenai Bridge between the first and second Tenjin Tunnels is the first expressway in Japan to be equipped with a membrane snow shelter.

The Onnenai Bridge is 58 m long, and the installation of snow shelters was considered from the beginning due to the risk of accidents caused by whiteout (a phenomenon in which visibility turns completely white due to snowstorms, etc.) in addition to the traffic congestion caused by snow removal and clearing operations due to heavy snowfall in the winter. In this case, if the entire length of the tunnel was connected by a shelter, the two tunnels and the shelter would be considered as one continuous long tunnel, which would greatly increase the construction cost. Therefore, a snow shelter and a snow shed (a roof with side openings to avoid snow) were combined to prevent air leakage, and a design plan was developed to make each tunnel a separate tunnel in terms of standards.

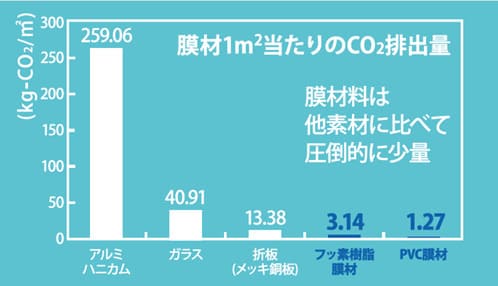

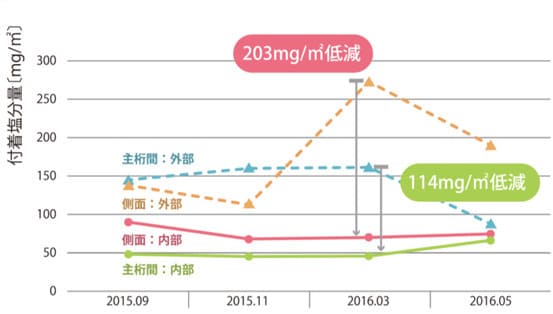

While steel shelters were initially considered, the membrane material was ultimately chosen because of its cost advantage, including the entire construction process, as well as its superior resistance to salt damage. The specific factor was the effect of snow-melting agents. The main ingredient of the snow-melting agent that melts snow on the road is calcium chloride (CaCl2). While it is effective in melting snow even in regions where the freezing point is as low as -50°C, the chloride is a rust and corrosion factor, and its effect on road facilities, especially metal structures such as steel shelters, has been an issue. In contrast, resin membranes are free from rust and corrosion even if chlorides adhere to them, and since metal structures account for only a small percentage of shelters, they were judged to be extremely superior to steel structures in terms of total cost, including maintenance.

In addition, it goes without saying that the safety and reliability of the membrane structure was thoroughly verified before it was adopted. For example, the installation of the shelter was designed to reduce the load on the bridge. In particular, it is important to reduce the snow load. The shelter shape is an onion shape with a projection at the top, and it has been proven with steel products that snow slides down more easily and does not accumulate on the roof as easily as in a simple arch structure. In adopting membrane materials for this shape of shelter, winter observations of actual construction properties have shown that membrane materials have the same active snow performance as steel snow shelters (with stainless steel plates).

Each performance, such as strength, impact resistance, and flame resistance, has also been tested under severe conditions as shown below, and it has been confirmed that the membrane material has sufficient performance as a material used for highway facilities that require high safety and reliability.

Reduction of driver stress due to improved visibility Membrane effects expected on ordinary roads

Installation of membrane snow shelters is not limited to highways. When installed on general roads in snowfall areas, they have a variety of benefits, including road safety and accident deterrence. One of the most significant differences, especially when compared to existing steel shelters, is its brightness. The translucency of the membrane is approximately 13%. During the daytime, the shelter lets in plenty of natural light, making it much more visible than steel shelters. Drivers can quickly recognize subtle changes in the road surface and take appropriate safety maneuvers such as slowing down, thereby greatly reducing the possibility of accidents.

In addition, light passing through the membrane material becomes soft diffused light. This low-contrast light is gentle to the driver’s vision and has the effect of reducing the “blending phenomenon” that occurs at tunnel entrances due to the large difference in illumination between the inside and outside, and the “evaporation phenomenon” that occurs at tunnel exits when sunlight suddenly shines through and the driver loses visibility for a brief moment. Above all, continuous driving in tunnel sections under artificial lighting is stressful for drivers. In this sense, in addition to its basic performance as a shelter to prevent snow from entering and the road surface from freezing, the brightness of the membrane is surely one of the most important factors when considering road safety.

Contributes to reduction of electricity consumption, information provision function by membrane and lighting, etc.

鋼製スノーシェルターの場合、日中から照明の点灯が必要となりますが、膜は日中は、極端な日陰などでなければ照明なしで一般道の走行にはほぼ支障のない明るさが確保できます。くわえて膜は光の反射率も高いため、夜間照明を効率的に反射させ道路を照らします。膜の持つ明るさ、その透光性能、反射性能は施設全体の電力消費量削減にも貢献します。

一方、膜は照明との親和性が高いことも大きな特徴の一つです。夜間、照明が点灯するとその光がシェルター全体を行灯のように照らし、昼間とはまったく違う意匠を浮かび上がらせます。この特性を利用し商業施設ではイベントや催事に合わせた照明計画などが実施されています。道路の場合にはまず安全性の確保が最優先となりますが、それを担保した上で、たとえば街おこしや地域イベントとの連動、時間や季節に合わせた照明の変化。さらには膜をサイネージとして利用し、渋滞情報、道路工事情報などドライバーへのさまざまな情報提供ツールとして利用するといった可能性も考えられます。

Click here for links to road-related products, etc.

Related Articles

- TOP>

- Taiyo Kogyo Column>

- Membrane snow shelters are now available! Membranes protect roads in winter.