Taiyo Kogyo Column

The innovation of membranes for road maintenance

As road assets concentrated after the period of high economic growth continue to deteriorate, it has become important to ensure safety through thorough maintenance and inspections. While maintenance and inspection work using new technologies such as nondestructive technology is being considered, Taiyo Kogyo has focused on improving the inspection work environment. The company has applied its membrane structure technology, which has been widely used in domes, arenas, and commercial facilities, to inspection scaffolds. By maximizing the characteristics of membranes, a safe, secure, and efficient work environment for reliable inspections is realized.

Aging Road Assets Entering an Era of Full-Scale Maintenance

Taiyo Kogyo proposes the use of membrane structure technology for road maintenance and upkeep.

Membrane structures may not be familiar to the civil engineering world, but they are a construction technology that is lightweight, thin, adaptable to a variety of designs, and highly durable. It is used in a wide range of fields, including large-space roofs for stadiums, arenas, and gymnasiums such as the Tokyo Dome and Saitama Stadium 2002, as well as railroad stations, commercial facilities, hospitals, and schools. The Tokyo Dome was completed in 1988, and the membrane material used for the roof has never been replaced.

Taiyo Kogyo has introduced “Bridge Wrapping,” which uses this membrane structure technology to cover bridges, protecting the structure and improving the landscape. We have also developed “Membrane Inspection Scaffolds,” which can be used as permanent inspection equipment with enhanced load-bearing capacity. Both of these technologies were registered as “Metropolitan Highway New Technology” in 2013 as “Bridge Exterior Membrane Construction Method” and in 2019 as “Membrane Inspection Scaffold” in “NETIS (New Technology Information System)” of the Ministry of Land, Infrastructure, Transport and Tourism.

Why is membrane structure technology necessary for road maintenance and inspection now? It is precisely because this field is important and requires various technological innovations.

Bridges and tunnels that were constructed intensively and regularly during and after the period of high economic growth will rapidly age, and in 10 years, more than 40% of bridges will be 50 years old. The Subcommittee on Roads of the Social Infrastructure Development Council of the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) stated in its “Proposal for Full-Scale Implementation of Measures against Aging Roads” (2014) that “We must take the helm for full-scale maintenance now. If we do not take the initiative in full-scale maintenance now, we will face fatal situations in the near future, such as collapsing bridges, that will affect human lives and social systems.

In response to this recommendation, the ministry enacted (in July 2014) a ministerial ordinance and notice urging inspections once every five years for tunnels and road bridges longer than 2 meters. Road managers are now obligated to conduct periodic close-up visual inspections. In July 2017, the “Technical Standards for Bridges and Elevated Roads (Road Bridge Specifications)” were also revised to strengthen the maintenance and management system for roads and bridges, one of the most important social capitals.

Major Revision Points of the Specification for Highway Bridges

1) 多様な構造や新材料に対応する設計手法の導入

2) 長寿命化を合理的に実現するための規定の充実

・設計供用期間100年を標準とした点検方法や手法、維持管理の方法を設計段階で考慮

3) その他

・熊本地震の実例を踏まえた対応など

軽く、柔らかく、耐久性に優れ、そして安全。ドームを始め多くの建設分野に革新をもたらしてきたように、今、大切な道路資産を守り、未来へと継ぐために膜だからできる、膜構造にしかできないことが、そこにあります。

Safety, security, and comfort Significantly improved efficiency of inspection work

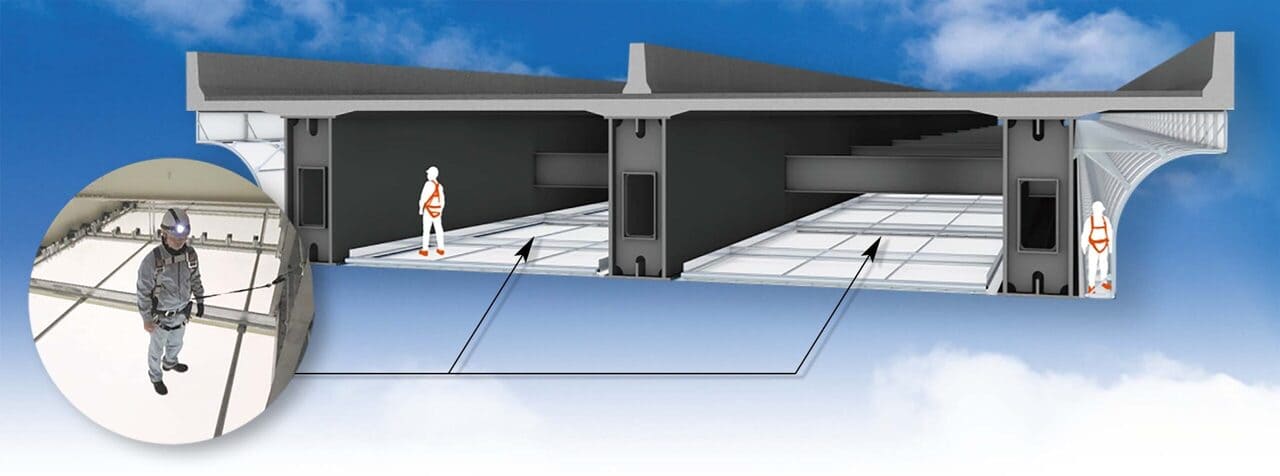

As shown in the figure, the basic structure of the membrane-type inspection scaffold is a membrane that wraps the bridge overhang and between the main girders with membrane panels, and is used as an inspection scaffold with a dedicated hatch for entry/exit and wires for safety belts inside. The membrane panels, which are anchored by special members, are strong enough for human inspection work, with a load capacity of approximately 350 kg (about 5 adults) in a typical design, and the load capacity can be further increased on demand.

Unparalleled light weight and disaster resistance

膜構造は高い強度を保ちながら、きわめて軽量という特徴があります。膜自体の重さは1kg/m2。金属製の橋梁パネルが80〜100kg/m2なのに対し、膜式点検足場はフレーム部材を含めても20kg/m2ほどしかありません。

軽量で柔軟性のある膜構造は下部構造体への負荷が少なく、躯体の変形や振動に対応する変形追従性にも優れているため、地震等の大きな揺れなどでも破損や部材落下のリスクは、他素材に比べ大きく軽減されます。また道路構造体から部材が剥離した場合なども膜材がクッションとなって受け止め、落下事故等の二次災害を防ぎます。

Bright space with no need for lighting

安全性をきちんと担保した上で、点検足場に膜を利用する大きなメリットがその明るさです。金属パネルで覆った足場の場合、作業空間は暗所となるため、点検のために照明機材を搬入する必要があります。一方、膜パネルは閉鎖空間でありながら可視光透過率約13%という透光性能によって、日中は自然光によって内部を常に明るく保ちます。

当社測定値では張り出し部内部で約3000lx、主桁間内部でも約200lxと、作業場照度を十分に確保できるため、通常の近接目視点検ならば照明機材は不要となります。

膜を透過した拡散光はコントラストが弱く、極端な日陰をつくらないため、手元確認作業の視認性など点検作業の効率化にも貢献します。くわえて膜式点検足場に使用する膜材は日射反射率約80%、紫外線は約99%カットするため、作業に十分な明るさを保ちながら、内部の極端な温度上昇を抑制します。

Reduced impact of inspections on the surrounding area and greatly improved the downtown landscape.

従来型の点検では目視確認を行うためクレーン等の重機によって作業員が上昇し、道路に沿って移動させる必要がありますが、都市部ではこうした点検作業にともなう渋滞の発生、歩行者通路への影響などが課題となっています。場所によっては重機の搬入等のために周辺道路の封鎖が必要な場所もあり、作業以前に事前調整が大変なケースもあります。

これに対して膜式点検足場は一箇所の出入り口から点検作業員が足場に入り、点検箇所に応じて足場内を移動することができるのにくわえ、照明機材も不要なことから、点検に伴う設備を最小限に抑えることができます。搬入から撤収までの作業効率の向上はもちろん、一般道路、駅や周辺施設への影響も少ないため、点検にともなう各所との事前調整もよりスムーズになります。

またむき出しの鉄骨やコンクリートを膜で覆う膜式点検足場は、点検以外の日常時には高架下をすっきり明るくする景観改善効果を発揮します。特に駅前や繁華街では歩行者の利便性を向上させ、街の賑わいを生むほか、夜間の防犯効果も高め安心・安全な街づくりに貢献します。

Significantly reduces chloride adhesion Effective in preventing rust on coastal roads

One of the main features of the membrane is that it protects the road structure from components that cause rust, corrosion, and deterioration by covering the structure with the membrane.

The membrane material does not require any special coating because it does not rust due to its performance, and covering with the membrane material cuts ultraviolet rays that affect the structure and greatly reduces the adhesion of chlorides, a major cause of corrosion. This is especially effective for road maintenance along coastal areas that suffer from rusting due to chloride adhesion.

Click here for links to bridge wrapping product pages, etc.

summary

いかに現状の資産を有効に活用し、未来へと引き継いでいけるか。そのためには既存技術のみに依存しないイノベーションが必要となってきます。『道路橋示方書の改定』によって多様な構造や新材料の導入を可能としたのも、より安心で安全な道路維持の解を求めるための新技術への期待を示すものと言えるでしょう。

太陽工業は創業以来、膜技術を追求し、その利用の幅を大きく拡げ、建築に新たな可能性を拓く素材としての地位を確立してきました。ご紹介した『橋梁ラッピング』『膜式点検足場』は、そんな私たちが培ってきた膜技術を、土木の世界へと拡げ、拓いていく製品です。道路、橋、トンネル‥‥。膜というイノベーションを通じて土木建築に新しい価値を提供していく。私たちの挑戦は続きます。

Related Articles

- TOP>

- Taiyo Kogyo Column>

- The innovation of membranes for road maintenance