Taiyo Kogyo Column

Example of seawall construction: Maxwall, which requires no skilled labor and can be constructed in a short period of time.

Table of Contents

When small and medium-sized rivers are damaged by rising water due to typhoons or torrential rains, conventional methods such as wooden fences, cast-in-place concrete, and cage construction have been the main restoration methods for small-scale restoration work. However, conventional methods are not suitable for small-scale restoration work,

- Cost and construction time will be required due to temporary closing

- Skilled workers are needed for jagokko workers.

For these and other reasons, it has been difficult, especially at the municipal level, to respond to a large number of damaged areas. Riverbank revetment construction using “continuous box-shaped steel frames” solves these problems and enables construction without using temporary barriers, in a short period of time, and without the need for skilled workers. This article introduces the method and examples.

What is Continuous Box Type Steel Frame?

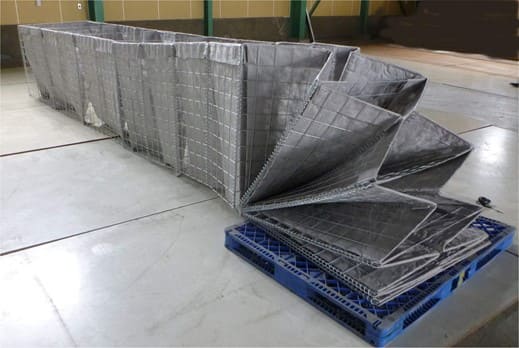

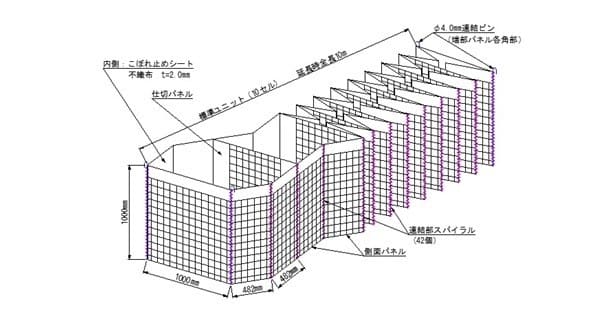

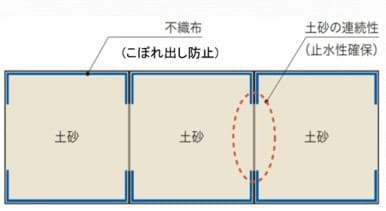

All of the examples shown here employ continuous box-type steel frames. Continuous box-type steel frames consist of multiple cages (steel frames) connected by coiled galvanized iron wire lattice panels, which can be divided, extended, and bent for installation. By lining the inside of the steel frame with non-woven fabric and filling it with locally generated soil, crushed stones, chestnut stones, etc., a continuous embankment can be easily and quickly constructed, and can be used for earth retaining, embankment raising, temporary embankment closure, etc.

Outline and Features of Continuous Box Type Steel Frame "MAXWALL

Maxwall uses lattice-like panels made of galvanized iron wire, which are durable enough to withstand use for about 10 years, making it suitable for temporary construction over a long period of time. Because of its high durability and the fact that it does not require any filling material, Maxwall was introduced in the areas affected by the Great East Japan Earthquake as a temporary earth embankment and earth retaining system for raising embankments and embankments, and has been installed in coastal areas using locally generated soil and concrete rubble recycled from rubble due to the shortage of materials such as crushed stone. The following is a brief introduction of its outstanding features.

Feature 3: High durability and can be used as a long-term temporary installation

While large sandbags can be used for only about 6 months to 3 years, Maxwall has a durability of more than 10 years on land and in the soil, and about 5 years in areas where seawater splashes. In the Great East Japan Earthquake, Maxwall was used for a long period of time in coastal areas as a temporary construction material for revetments and earth retaining works.

Feature 4: Any filling material can be used, including earth, sand, crushed stone, and locally generated soil.

It can be used not only for earth and sand, but also for crushed stone and chestnut stone, and can also be used as a residual concrete formwork.

Feature 5: Can be stacked, split, extended, and bent

The standard size (one unit) consists of a series of ten 1-meter cubic steel frames (cells), which can be freely divided, extended, and bent to suit the scale of construction and site conditions. It can also be stacked, allowing it to be flexibly adapted to the shape of the site.

Feature 6: 25% shorter construction period than conventional large sandbags

It does not require skilled labor and can be installed by five people for approximately 40 meters per day. This is an approximate 25% reduction in construction time compared to large sandbags.

Related Articles

- TOP>

- Taiyo Kogyo Column>

- Example of seawall construction: Maxwall, which requires no skilled labor and can be constructed in a short period of time.