Taiyo Kogyo Column

Drive-through PCR laboratory” for the 6th wave that may come this fall/winter: measures to prevent the spread of new coronavirus infection: What is the solution proposed by tent manufacturers?

2020.06.08

新型コロナウイルスの感染による世界的な感染拡大は、世界の医療現場は逼迫しています。国内の医療現場は医療リソースを守るために、医療従事者や検査利用者の2次感染を防ぎ、より安全性を高めたな検査体制を構築することが求められています。

これを可能にするのが、テントを用いた『ドライブスルー型PCR検査所』です。

その機能や事例を詳しくご紹介します。

What is a PCR laboratory for novel coronaviruses? An Overview and Challenges

The method currently used to diagnose new coronavirus infection is the “PCR test” using the nucleic acid amplification method (PCR method). Medical personnel wearing protective clothing called PPE to prevent infection use a dedicated test kit to collect a specimen by inserting a cotton swab through the nose of the person to be tested, but the person collecting the specimen is at high risk of infection due to the tendency to cough and sneeze. As of April 2020, Japan has an established system of 22,000 tests per day. However, only about 9,000 tests are actually performed. Since testing requires a certain amount of time and human resources, public health centers are responsible for managing the testing so that the medical field does not become overwhelmed by the testing and cause a collapse of medical care. The medical field is about to face a manpower shortage due to the new coronavirus. In addition, tests conducted in medical facilities face all kinds of problems, including the risk of nosocomial infections caused by contact (directly or indirectly) between infected persons and medical personnel, and between infected and non-infected persons, the time and effort required to disinfect hospital premises, and the shortage of medical equipment and materials. The current PCR testing system has three major problems: testing cost, infection risk, and lack of medical equipment and materials.

What is a drive-through inspection station? Why should air tents be used?

One effective solution to this problem is a “drive-through PCR laboratory. This is a specialized temporary facility that allows test subjects to undergo testing while they are still in their private vehicles, and was introduced in the past at quarantine centers such as those near airports in summit cities during the H1N1 influenza pandemic.

(Image of a drive-through inspection station)

This method is also effective in PCR testing for new coronaviruses, and is expected to reduce human resources at medical facilities and the risk of nosocomial infections. However, when using general construction materials, even temporary construction requires a certain amount of time and specialized construction workers. As a result, it is not flexible enough to be set up in a short period of time in an emergency, or to be set up in any location on the premises of a medical institution. This is why drive-through PCR laboratories using “medical air tents” are attracting attention. This allows for convenience and flexibility in setup without compromising the laboratory’s functionality. The following is a detailed explanation of the advantages of air tents.

What is an air tent?

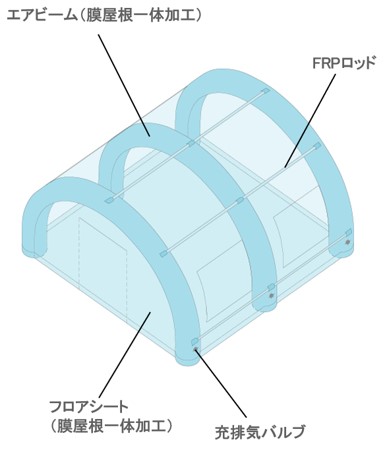

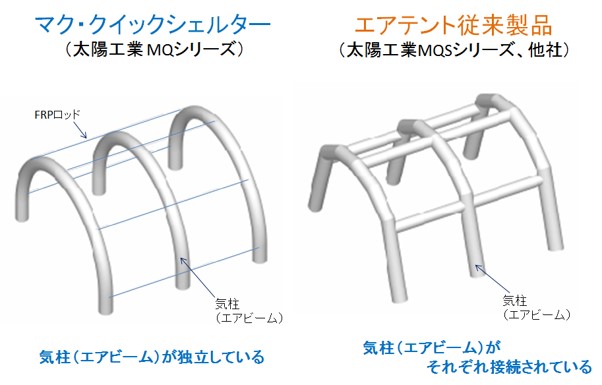

Unlike conventional pipe tents, this is a generic term for tents with a structure in which the tent is extended from the stored state, FRP rods are connected, and three pillars are inflated by air power. It is an emergency temporary space.

McQuick Shelter, an excellent medical air tent

One of the best performing medical air tents is the McQuick Shelter offered by Taiyo Kogyo Corporation, a long-established tent manufacturer that will soon celebrate 100 years in business. The following is an introduction to its superior functionality.

Compact and easy to store

The McQuick Shelter medical air tent is a hybrid tent composed of three independent air columns and orthogonal horizontal connecting members, making it compact and easy to store. It takes up little space because it fits into a minimum size of 80cm x 80cm x 35cm, and since space is available above the folded tent in the wagon cargo area, storage of other equipment is not overwhelmed. It can also be quickly retrieved in an emergency.

Lightweight and easy to carry

The McQuick Shelter has fewer air column sections than the air tents of other companies, resulting in less air capacity and much less weight. (*Air beams are the columns that hold the air. ) The fabric is made of polyester fiber cloth with a polyvinyl chloride resin coating instead of rubberized fabric, making it even lighter.

The weight of the main unit starts at about 55 kg, which is light enough to be carried by only two persons. It can also be folded down to a size that can be loaded into a car, making it extremely easy to transport.

Easy to install, just unfold and inflate.

Installation is completed in 10 minutes by simply carrying the unit to the installation site, unfolding it, and feeding air into it with an electric blower. Since no heavy lifting is required and no specialized knowledge or familiarity is needed, even women and inexperienced people can easily handle the installation.

Can be set up by just two people

While conventional pipe tents generally require four people to set up, the McQuick Shelter medical air tent can be deployed by only two adults per set. As shown in the photo below, all you have to do is wait for the tent to inflate with air, and you can set it up with just the people supporting the two ends. The fact that only half the manpower is needed means that in an emergency, setup can proceed twice as efficiently.

Can be installed in as little as 5 minutes

The following is an idea of the time required to set up a McQuick shelter, which can be completed in as little as 3 minutes.

- Tent deployment (1-2 minutes)

- Rod installation (1-2 minutes)

- Filling air (1-3 minutes) * Can be done manually (about 10 minutes)

Since air filling can be done manually, it can also be used when a power source (generator) for an air pump is not available. Even manual filling can be done in about 10 minutes.

Independent air column and dual tube construction allows on-site repair

In general air tents, the air columns are all connected, so if a hole is made in one part, air leaks out and the whole tent collapses, requiring transportation to a specialized factory for repair. On the other hand, McQuick shelters have independent air columns, so there is no risk of complete collapse, and the double-layered construction of the air columns prevents damage from reaching the inside, allowing the inner bag tube to be replaced on site and the tent to be restored without having to replace the entire tent. The tent can be restored without replacing the entire tent by replacing the inner bag tube on site.

Can be removed in just 10 minutes

Removal of the McQuick shelter is quick and easy. Simply push the exhaust button to release the air, and the remaining air can be sucked in with a blower to complete the removal process in about 10 minutes.

More than 1,800 cases nationwide

We have a track record of 1,800 air tents “McQuick Shelter” in Japan, including government offices, fire departments nationwide, medical institutions, and electric power companies, etc. During the 2009 H1N1 influenza pandemic, we developed and delivered 200 negative pressure tents for medical use. We are a long-established manufacturer of membrane structures and tents and an industry leader that will soon celebrate 100 years in business. We are a leading manufacturer of membrane structures and tents, and have been in business for over 100 years. and our goal is to deliver an inspiring and comfortable environment by exploiting the infinite possibilities of membranes.

Advantages of the "drive-through PCR laboratory" proposed by Taiyo Kogyo for new coronavirus countermeasures

Drive-through PCR-type laboratories using the McQuick Shelter, a medical air tent, offer the following outstanding advantages

Reduce the risk of nosocomial infection and simplify disinfection methods

The drive-through method reduces the risk of infection by placing the tent outdoors where adequate ventilation can be expected, while in the hospital, the risk of secondary infection and indoor disinfection methods are time consuming. In addition, the indoor sheets inside the tent can be easily replaced, washed, and disinfected inside the tent.

Protecting the privacy of subjects undergoing testing

Protecting the privacy of examinees in laboratories that are closed to the public becomes very important. It is required to provide a comfortable testing space for both healthcare professionals and examinees as much as possible, and it is also requested that testing be conducted in a safe space that takes into consideration the sentiments of local residents.

Comfortable environment with air conditioning, etc.

Although it will be quite hot in the outdoor space from June onward into the summer, dedicated air conditioning equipment, spot coolers, and fly sheets will make it possible for medical personnel to perform inspections in comfort.

Lightweight, easy to carry and can be used anywhere

Flexibility in setup is extremely important for temporary spaces where you never know when or where you will need it. Weighing only 40 kg or less and able to fit in the back of a car, the McQuick Shelter can be easily transported and deployed wherever needed.

Can be installed in a short time

With two adults, installation can be completed in as little as five minutes. No special tools or specialized skills are required, making it easy for anyone to set up.

rain or shine

The tent can be operated without problems even in the rain, as the roof, walls, and floor are all one integrated structure. The tent is also fully wind-resistant, so it can be used stably even in strong winds.

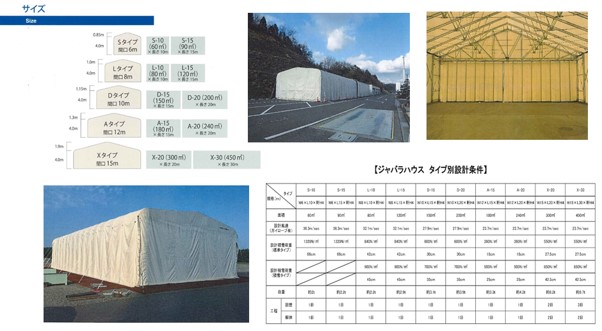

Sizes and various applications to meet your needs

The optimum size tent is available depending on the space and scale of the location where it is to be installed. In addition to existing sizes from W3m to W5m, we can also accommodate custom orders, and our W6m tent can accommodate a high-standard ambulance. In addition, we are receiving an increasing number of proposals for use as a disinfection space for medical personnel, a rest area, and a space for donning and doffing PPE protective clothing, etc. (See separate PDF catalog data).

Drive-through PCR laboratories have already been introduced in Tottori, Nara, Niigata, and Nagoya

Drive-through PCR laboratories using the “McQuick Shelter” have already begun to be introduced in various locations. In April 2020, Tottori Prefecture will be the first prefecture in Japan to introduce the system, starting with three medical facilities in the prefecture, and plans are in place to expand the introduction of the system in the future. At the same time, medical facilities in Nara Prefecture are also adopting “Mc-Quick Shelter” in their SCUs (wide-area transport base temporary medical facilities). (See image) The introduction of the drive-through PCR laboratory has brought great results, reducing the time required for testing from the two hours it used to take to 15 minutes.

《Photographs of results》

(Air tent at SCU, Nara, Japan)

(Drive-through photo of a certain location in Nagoya City)

(Drive-through photo in a certain metropolitan area)

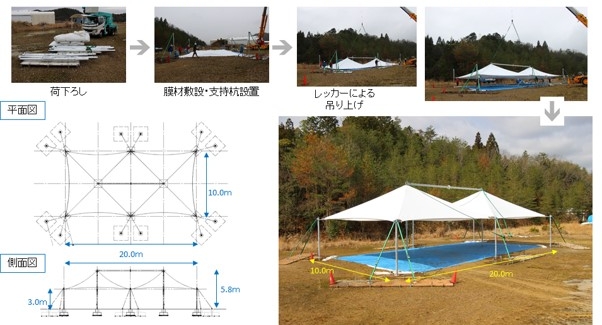

Further efficiency is achieved by utilizing a "towing exhibition tent" for large inspection stations.

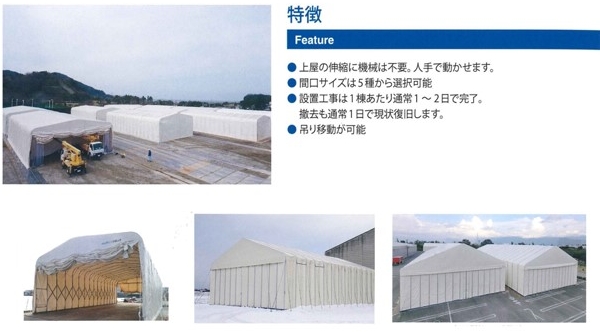

When many inspections are to be conducted at once in a large area, such as on the grounds of a large medical facility, a large inspection station can be set up using a “wrecker spread tent”. Support stakes are welded and bolted to the substrate, and the tent is lifted and installed by a wrecker. This is a large construction project and requires more time than the McQuick Shelter, but it further improves inspection efficiency by enabling multiple drive-through inspection responses at once using a large tent 10 m or more in width.

Other tents: frame tents, tent warehouses, etc.

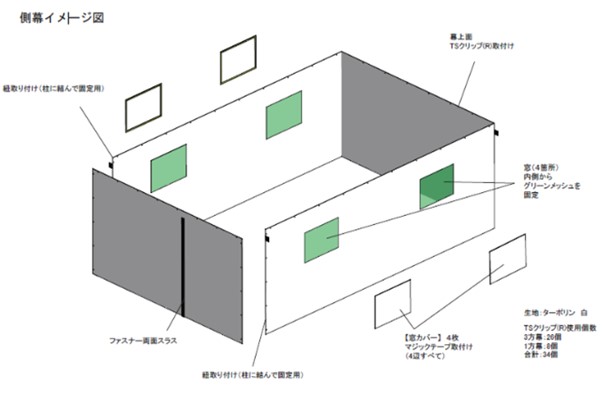

For long-term temporary inspection stations that are not repeatedly set up, taken down, and moved, solutions such as frame tents and tent warehouses are also available. In addition to drive-through inspection stations, they can also be used as storage areas for accompanying materials. Some of the variations are listed below.

frame tent

Mobile bellows-type large tent

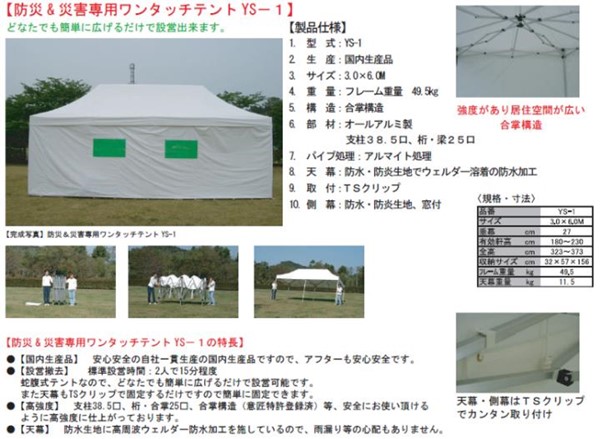

One-touch side-membrane tents

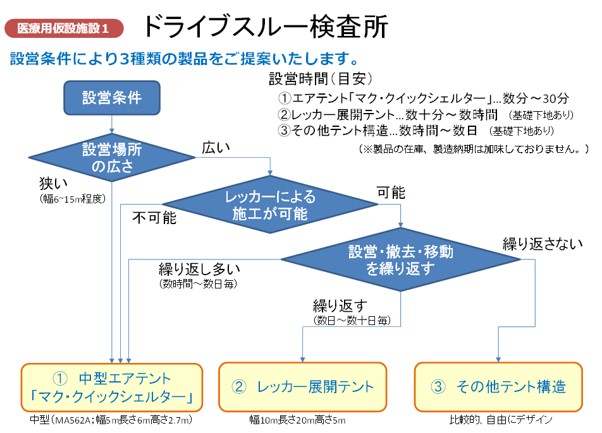

Different proposals are possible depending on the set-up conditions

Depending on the conditions at the site where the temporary facility is to be set up, we can propose the best tent solution for each. Please refer to the diagram below for reference. If you have any questions, please contact us using the contact form and a representative will be happy to explain the details.

Taiyo Kogyo's drive-through PCR laboratory is also available for rent.

Taiyo Kogyo’s drive-through PCR laboratories are available for sale as well as for reasonable rental.

For more information, please contact us using the inquiry form.

summary

Medical facilities conducting PCR testing for novel coronaviruses face two challenges: manpower shortage and infection risk, and one solution to these problems is the “drive-through PCR laboratory. By using tents as temporary facilities, laboratories can maximize efficiency. Taiyo Kogyo hopes to contribute to the containment of the spread of the new coronavirus by using the technology and know-how it has accumulated over the years regarding membranes and tents. We hope you will consider our “drive-through PCR laboratories” using tents and other solutions to realize a safer medical care system.

Related Articles

- TOP>

- Taiyo Kogyo Column>

- Drive-through PCR laboratory” for the 6th wave that may come this fall/winter: measures to prevent the spread of new coronavirus infection: What is the solution proposed by tent manufacturers?