Taiyo Kogyo Column

Introduction of earth retaining works that do not require large sandbags│Examples of emergency restoration from landslides

In particular, Japan’s climate is rainy during the rainy season and typhoon season from late summer to autumn every year. Small landslides caused by torrential rains and typhoons occur on a daily basis, and local governments, such as municipalities, respond to these disasters. In emergency recovery from landslides, large sandbags and cages are generally used for earth retaining works, but municipalities are faced with the following issues on a daily basis.

- Narrow lots make it difficult and costly for large heavy equipment to enter for transport and installation

- We would like to utilize locally generated soil, but sometimes we cannot use locally generated soil in large sandbags.

- Requires skilled workers with special skills.

- Low durability, requiring frequent repairs and reinforcement

One way to solve these problems is to use “continuous box-shaped steel frames” for earth retention. This article includes several case studies, so please take a look at them for reference. At the end of the article, we will also provide contact information for inquiries regarding “continuous box-type steel frames.

What is Continuous Box Type Steel Frame?

ここで紹介する事例では、すべて連続箱型鋼製枠を採用しています。

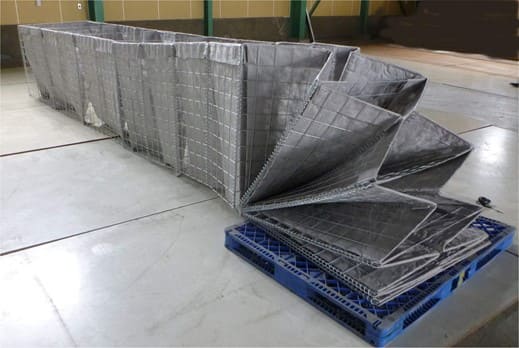

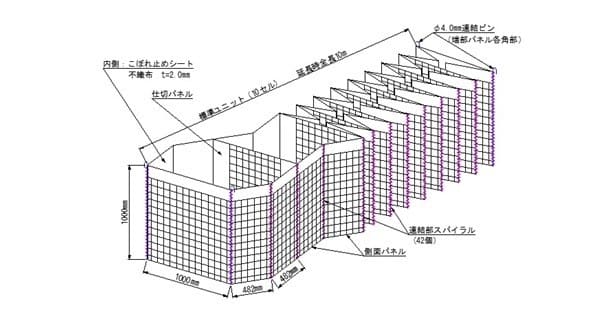

連続箱型鋼製枠は、亜鉛メッキ鉄線製の格子状のパネルをコイル連結したカゴ(鋼製枠)を複数接続した構造で、分割・延長・屈曲させて設置できます。鋼製枠の内側に不織布を張り、現地発生土や砕石、栗石等を中詰めすることで、連続した土堤を簡単・迅速に構築でき、土留め、堤防嵩上げ工、仮締切工等に使用できます。

Outline and Features of Continuous Box Type Steel Frame "MAXWALL

Maxwall uses lattice-like panels made of galvanized iron wire, which are durable enough to withstand use for about 10 years, making it suitable for temporary construction over a long period of time. Because of its high durability and the fact that it does not require any filling material, Maxwall was introduced in the areas affected by the Great East Japan Earthquake as a temporary earth embankment and earth retaining system for raising embankments and embankments, and has been installed in coastal areas using locally generated soil and concrete rubble recycled from rubble due to the shortage of materials such as crushed stone. The following is a brief introduction of its outstanding features.

Feature 1: High stability

Large sandbags often used for temporary construction are not connected and not integrated, making them vulnerable to external forces and unstable, such as collapsing if the load is concentrated in one place. Maxwall, with its continuous steel frame, can withstand more than four times the external force (approximately 16 kN) of large sandbags, demonstrating its high stability.

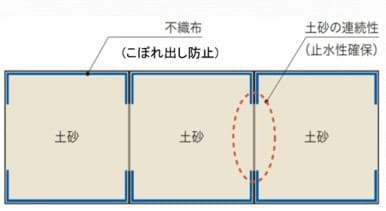

Feature 2: Watertightness due to sediment continuity

The inner frame (the red frame in the figure below) is not covered with non-woven fabric, and the continuous filling material such as sand and soil ensures high water sealing performance that cannot be achieved with large sandbags.

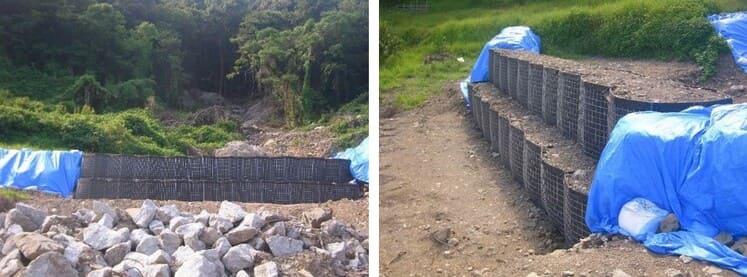

In this case, the company was considering widening a forest road in the mountains as part of a disaster recovery project, but was faced with the problem that the site was too narrow to allow cranes and other large heavy equipment to enter, and large sandbags could not be carried in.

Therefore, Maxwall was adopted because it is compact, easy to transport and deploy onsite, and can be flexibly processed according to the shape of the site. In this case, there was a risk of rainwater overflowing the mountain side channel and flowing into the Maxwall area, causing the filling material to run off.

| client | Ibaraki City Hall |

| Construction Location | Ibaraki City, Osaka |

| Site Situation | among the mountains |

| Type used | MW-1000 (extension 10m/unit, height 1m) |

| Filling material | Purchased soil (crushed stone) |

| Quantity used | 8 units (80m) |

| Number of tiers | 6 tiers |

| Construction Period | April, 2008 |

| Construction time | Approx. 3 days |

Repair of slope at Izumi Shoryo Elementary School, Sendai (Typhoon No. 19 disaster in 2019)

Related Articles

- TOP>

- Taiyo Kogyo Column>

- Introduction of earth retaining works that do not require large sandbags│Examples of emergency restoration from landslides