Taiyo Kogyo Column

Example of “Continuous Box Type Temporary Levee” that ensures effective flood control

Levees along rivers and coastal areas play an extremely important role in Japan, where typhoons visit every year. However, due to various reasons, there are approximately 1,500 km of uncompleted levees that are insufficient in height and width. The risk of flood damage due to overflows from rivers and levees has increased due to the recent frequent abnormal rainfall, but full-scale levee raising requires time to secure new land and complete the raising. Therefore, emergency measures are being taken by “temporarily raising the levees” until the main levees are completed. In order to raise the levees (secure the height), it is necessary to secure the necessary width (land for levee construction). However, it is not always easy to secure land for this purpose in some areas. Large sandbags, which are often used for “temporary embankment raising” due to their low cost, have weaknesses such as low water sealing performance, risk of tipping over or being washed away due to lack of integrity, and short service life. Large sandbags used for temporary raising have the risk of leaking water through the gaps and eroding the backwall (demonstration test). The “Continuous Box Type Temporary Embankment” achieves high water sealing performance, stability due to its excellent integrity, short construction period, and long service life at the same time. This method, which can add high flood control effect to incomplete levees with insufficient height from tomorrow, will be introduced in detail with specific examples with pictures. Please take a look at this method, which can be applied to small-scale restoration work and boasts a wealth of experience in its adoption by municipalities such as cities, wards, towns, and villages.

What is Continuous Box Type Steel Frame?

ここで紹介する事例では、すべて連続箱型鋼製枠を採用しています。

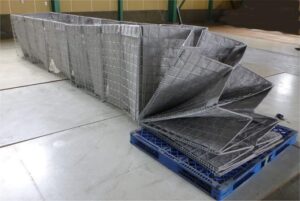

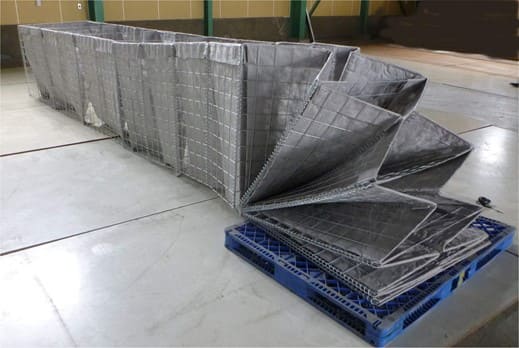

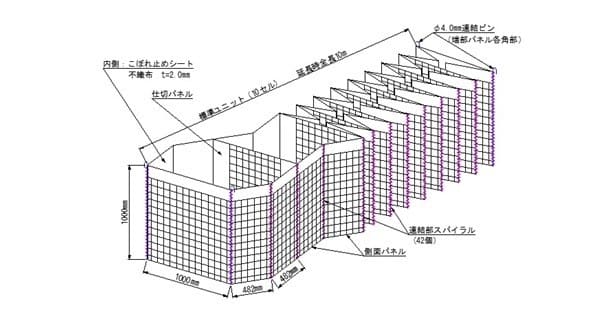

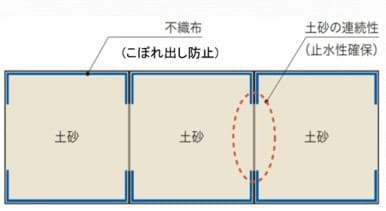

連続箱型鋼製枠は、亜鉛メッキ鉄線製の格子状のパネルをコイル連結したカゴ(鋼製枠)を複数接続した構造で、分割・延長・屈曲させて設置できます。鋼製枠の内側に不織布を張り、現地発生土や砕石、栗石等を中詰めすることで、連続した土堤を簡単・迅速に構築でき、土留め、堤防嵩上げ工、仮締切工等に使用できます。

Feature 1: High stability

Large sandbags often used for temporary construction are not connected and not integrated, making them vulnerable to external forces and unstable, such as collapsing if the load is concentrated in one place. Maxwall, with its continuous steel frame, can withstand more than four times the external force (approximately 16 kN) of large sandbags, demonstrating its high stability.

Related Articles

- TOP>

- Taiyo Kogyo Column>

- Example of “Continuous Box Type Temporary Levee” that ensures effective flood control