Taiyo Kogyo Column

Example of temporary construction: How to realize a temporary retaining wall with short construction period and long durability without using large sandbags

Japan is a country of rain and mountains. Landslides of large and small scale occur frequently in many places, and earth retaining works and temporary standby retaining wall construction have become routine tasks for local governments. Landslides that occur on mountain roads and forest roads essentially require construction work such as concreting the slope, but it is not easy to take immediate and thorough action with the time and budget given to local governments. Therefore, temporary construction work is generally carried out, but there are challenges here as well.

Large sandbags are often used in construction projects because of their high cost advantages, and transporting and installing them requires heavy equipment such as large trucks and cranes to be brought to the site. However, forest and mountain roads are often too narrow to accommodate such heavy equipment. In addition, the service life of large sandbags is said to be about three years at most, and repair work is often required at many locations where they have been in place for a long time after temporary installation. The “Continuous Box Type Steel Frame” solves these problems, shortening the construction period by its high workability regardless of the site, and realizing stability and long-term durability at the same time by its excellent integrity. The “Continuous Box Type Steel Frame” makes it possible to create a temporary standby retaining wall with strong integrity. This paper introduces this construction method in detail with examples with photographs. We hope that civil engineering project personnel in public offices and local governments will take a look at the contents of this report.

What is Continuous Box Type Steel Frame?

ここで紹介する事例では、すべて連続箱型鋼製枠を採用しています。

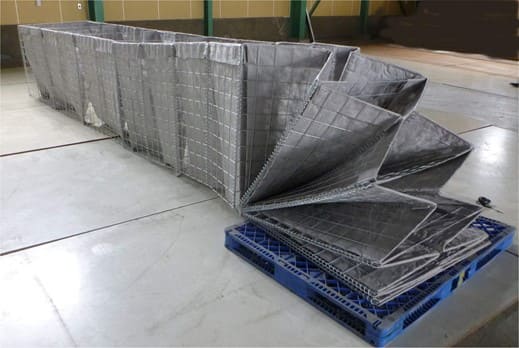

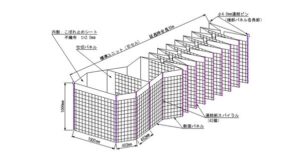

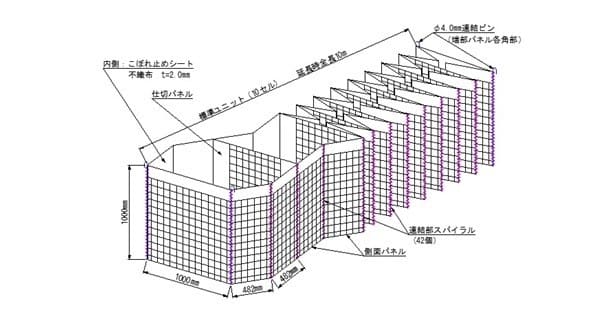

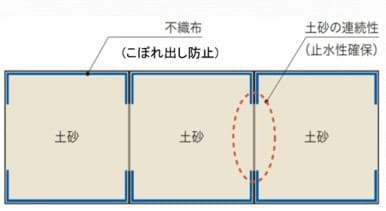

連続箱型鋼製枠は、亜鉛メッキ鉄線製の格子状のパネルをコイル連結したカゴ(鋼製枠)を複数接続した構造で、分割・延長・屈曲させて設置できます。鋼製枠の内側に不織布を張り、現地発生土や砕石、栗石等を中詰めすることで、連続した土堤を簡単・迅速に構築でき、土留め、堤防嵩上げ工、仮締切工等に使用できます。

Related information: Download Slope Protection Resources

Outline and Features of Continuous Box Type Steel Frame "MAXWALL

Maxwall uses lattice-like panels made of galvanized iron wire, which are durable enough to withstand use for about 10 years, making it suitable for temporary construction over a long period of time. Because of its high durability and the fact that it does not require any filling material, Maxwall was introduced in the areas affected by the Great East Japan Earthquake as a temporary earth embankment and earth retaining system for raising embankments and embankments, and has been installed in coastal areas using locally generated soil and concrete rubble recycled from rubble due to the shortage of materials such as crushed stone. The following is a brief introduction of its outstanding features.

Inquiry about Continuous Box Type Steel Frame

We have introduced a new option to solve conventional problems in earth retaining works such as temporary standby retaining walls, using the continuous box-shaped steel frame Maxwall.

Although Maxwall is a temporary material, it can withstand long-term use and shorten the construction period. In addition, it is an excellent construction method that can reduce overall costs because it does not require special skilled workers or skilled laborers.

It has been widely adopted by local governments, especially as a solution for sites where land is limited or a high service life is required. To learn more about Maxwall or to contact a representative, please visit the following link

> Taiyo Kogyo Corporation Continuous box-type steel frames “Maxwall

Related Articles

- TOP>

- Taiyo Kogyo Column>

- Example of temporary construction: How to realize a temporary retaining wall with short construction period and long durability without using large sandbags