Taiyo Kogyo Column

Types and New Methods of Slope Protection│Low-cost Methods that Require No Heavy Machinery or Specialized Skills

2019.12.04

Slopes are artificial slopes created by cutting or filling. In mountainous and rainy Japan, slopes are always unstable and vulnerable.

Slopes are at risk of collapse and require protection and reinforcement to prevent erosion and collapse. However, each construction method has its own advantages and disadvantages.

In this issue, we will introduce various methods of slope protection construction and new solutions.

Click here for theConcrete Canvas product page:

For inquiries about our products,click here.

What is slope protection work?

Slope protection is a method of preventing erosion and weathering of embankments and cut slopes. For example, the slope is covered with plants or structures to provide stability.

Specific construction methods include

– Vegetation and mortar spraying with turfing, seed spraying, etc.

– Free-frame construction to build concrete grids

– Block piling

– Stretched stone construction

These compensate for the fragility of artificial sloping surfaces and prevent rockfall and collapse.

See also:Download Slope Protection Resources

Methods of constructing slope protection works

法面保護工は以下の2種に分類されます。

①植生を用いる「植生工」

②コンクリート等の構造物を用いる「構造物工」

(1) Vegetation works

法面に植物の種をまく、もしくは苗木を植えて植物を繁茂させて、表層部の保護を図ります。植物は生育して法面を覆い、雨水による法面の浸食を防ぎます。風化も抑制します。また植物の根が土をしっかりと保持して土砂崩れを防ぐ効果も期待できます。

自然環境や景観の保全、温暖化対策としても有効とされ、他の工法と組み合わせて用いられる事も多いです。

There are several types of revegetation work, including “seeding work,” which uses seeds for revegetation, “planting work,” which uses turf, trees, and other plants that have already grown, and “sapling installation and spraying work,” which combines planting saplings and spraying seeds. The most suitable greening method is selected from various perspectives, including geology, landscape, construction period, and surrounding environment.

(2) Structural Engineering

法面保護を行う地山が土砂や軟岩の場合は風化の影響を受けやすく、構造物による法面保護工が行われます。「構造物工」とは、板柵、籠、コンクリートなどを用いて法面の強化をはかる工法です。

構造物工は法面表面の浸食や風化への対策だけではありません。法面(すべり)の深い箇所での崩壊や崩落へ対策が求められる場合は、アンカーや杭などが地山に挿入されますが、これらも構造物工に含まれます。

Insert anchors, stakes, etc. into the ground

Plank fences are driven perpendicular to the slope to control sediment runoff. When combined with vegetation work, plants are planted between the board fences. In “cage construction,” special baskets called “jakago” or “futon-kago” are placed on the slope surface or slope bottom. The “jakago” is mainly used to prevent erosion on slopes with large amounts of spring water or surface water, while the “futon-kago” is widely used for soil retention in disaster restoration. A retaining wall is a temporary structure that prevents soil from collapsing. Another feature of cage construction is that the cage can be filled with natural stone, so it does not overpower the landscape.

Example of futon basket

コンクリートによる法面の被覆は、その施工方法から大きく三つに分けることが出来ます。すなわち、「現場打ちコンクリート」と「モルタルコンクリート吹付」、「プレキャストコンクリート」です。

現場打ちコンクリートとは、その名の通りコンクリートを現場で打設することを指します。生コン工場のプラントで配合された生コンクリートをコンクリートミキサー車が現場まで運び、コンクリートポンプ車などで圧送、現場に設置した型枠内にコンクリートを流し込みます。

After concrete is placed, the formwork is removed after appropriate curing. It is mainly used to construct structures such as retaining walls and formwork. Retaining walls are walls that prevent the sides of cliffs and embankments from collapsing, while formwork is a lattice of mortar and concrete frames used in construction. It stabilizes the slope.

Image of legal frame

モルタルコンクリート吹付とは、吹付機を用いて、モルタルコンクリートを圧縮空気によって吹き付ける工法のことをいいます。一般的な施工手順として、清掃後の法面にラス網と呼ばれる菱形金網を固定した上で吹付が行われますが、これはコンクリートの亀裂や剥離の防止を目的としています。吹付されるモルタルコンクリートは現場に設けられたプラントヤードで配合され、デリバリーホースを通り法面まで圧送されます。法面全面の被覆や法枠、水路など幅広い用途で用いられています。

プレキャストコンクリートとは、工場であらかじめ製造されたコンクリートを指しています。二次製品のため品質が均一であるほか、コンクリートの硬化養生や、型枠の組み立て脱型の作業を現場で行う必要がないため、工期の短縮が図れるなどのメリットがあります。プレキャストコンクリートは主にコンクリートブロックや法枠ブロックとして用いられ、設置や運搬にはクレーンやバックホウなどが使用されます。

Related information: Download Slope Protection Resources

New slope construction

In recent years, the Ministry of Land, Infrastructure, Transport, and Tourism (MLIT) has strongly promoted i-Construction in order to promote productivity in the construction industry. Slope work is no exception to this trend, and the use of ICT in the field has already begun.

For example, 3D laser scanners are being used to create 3D data for calculating the amount of excavated soil, measuring the length of beams, and controlling the workmanship of the sprayed area of slopes. Slope construction is also evolving rapidly with recent technological developments, and it will be important to have a broad perspective not only in terms of construction methods such as ICT but also in terms of materials.

Concrete Canvas,” which we will introduce hereafter, has completely new features as a method of covering slopes with concrete, and has already been adopted in 47 prefectures in Japan, and is steadily gaining attention in recent years.

What is an effective concrete canvas for slope protection?

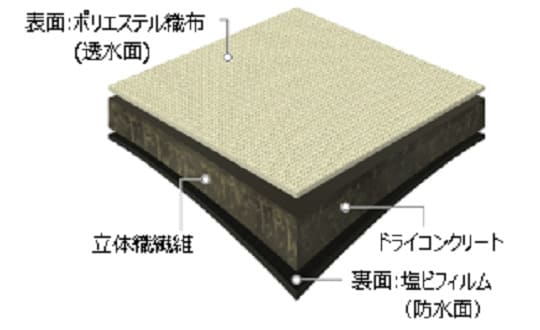

Concrete Canvas is a composite material of concrete and canvas (fabric) that hardens when moisture is added. As explained in the section ” Specific Measures to Prevent Collapsing Slope Surfaces,” Concrete Canvas has the advantages of cast-in-place concrete, sprayed mortar concrete, and precast concrete, and is easy to install, durable, and flexible.

Slope protection with concrete canvas

workability

One concrete canvas weighs approximately 70 kg. Since it can be freely cut on site, it can be transported and installed by hand even in areas where heavy machinery is not allowed. This eliminates the need for plant installation and securing heavy equipment, and reduces costs.

In addition, the construction of a concrete canvas requires only materials, pins and screws for anchoring/joining, and water. The only work required to construct the concrete surface is laying and watering, and no special skills, such as spraying or formwork, are required.

durability

The compressive strength of 18 N/mm2 for general unreinforced concrete and 15 N/mm2 for shotcrete mortar concrete are considered to be the standard strength. On the other hand, cement is used for concrete canvas, which shows a strength of 40 MPa (40 N/mm2) or higher in a compression test after hydration reaction.

In addition, the concrete canvas has been tested for weather resistance to British Standards to ensure that it can withstand an outdoor environment for at least 50 years.

flexibility

Concrete canvas has the properties of a fabric until it begins to harden, making it flexible enough to follow the complex shapes of the ground. It can be cut with a cutter knife, allowing for fine adjustments to suit the site, and can be used not only for prepared slopes, but also for emergency concrete covering of uneven surfaces or disaster areas. The flexibility of the system has also been used for various applications, such as reinforcing drainage channels.

Concrete canvas that flexibly follows uneven surfaces

summary

法面工事の新機軸「コンクリートキャンバス」は、コンクリート面構築による法面保護工を革新する材料です。

現場打ちコンクリートではミキサー車とポンプ車が必要です。モルタルコンクリート吹付ではプラントヤードが、プレキャストコンクリートではクレーンなどが必要となりますが、コンクリートキャンバスの登場により、これらの重機類がなくても施工が完了できるようになりました。

また、型枠工や吹付工のような特殊技能者がいなくても、法面をコンクリートで被覆することができます。

Furthermore, the quality of concrete canvas is homogeneous because it is a secondary product. The surface finish will not vary from one contractor to another. Also, because it can be laid as a flexible sheet, it conforms to the shape of the slope surface as well as sprayed mortar concrete.

It is easy to use, low cost, and its durability reduces post-construction maintenance costs. We already have various examples of introduction of this system, including local public organizations, so please visit our official website.

national land enterpriseへの

Contact us

Related Articles

- TOP>

- Taiyo Kogyo Column>

- Types and New Methods of Slope Protection│Low-cost Methods that Require No Heavy Machinery or Specialized Skills