Taiyo Kogyo Column

Introduction of factors that cause concrete channels to deteriorate and easy and effective repair methods

2019.12.02

日本はモンスーンアジアの東端に位置し、年平均1718mmの降水量があります。これは世界平均(880mm)の約2倍に相当し「多雨の気候」と言えます。そして、日本人の主食である米を収穫する水稲耕作は大量の水を必要とします。

そのため、多くの地域で水路工事の取り組みが継続的に実施されています。その反面、時と共に水路は必ず劣化をしていきます。

今回は、コンクリートの水路における劣化と、その際の対策についてご説明していきます。

Deterioration of concrete channels

Deterioration factors of concrete channels can be classified into two categories: (1) internal factors and (2) external factors.

internal cause

Internal factors are those caused by materials, design, and construction. Concrete is formed from cement, aggregate, and water, and the design determines the cement mix, finish, cover, joint structure, and other factors that affect the rate of deterioration. Changes in design standards, cement material quality, and construction methods themselves also affect the rate of deterioration.

プラントから現場へはミキサー車で運搬しますが、プラントからの距離を考慮したり、プラントで混ぜ合わせたコンクリートが運搬中に分離しないよう気を使っています。

施工に関しては、十分な締固めがなされていないことや養生が不十分なことが打設後の劣化要因となりますので、各社注意して施工に取り組んでいます。固まる前のコンクリートはセメントミルクと呼ばれ、型枠の中全てに均一に行き渡るように流動させて形どおりに仕上げています。

external cause

External factors are those associated with the environment in which the waterway is located. In addition to natural conditions such as air temperature, temperature, moisture, and solar radiation, they also originate from regional factors such as salinity from the ocean and the effects of anti-freeze spraying. Thus, in addition to human factors, concrete deteriorates due to various factors such as temperature, moisture penetration, frost damage, and chemical reactions.

As deterioration causes frequent shrinkage and cracking in concrete areas, the erosive action of running water adds to the wear and tear. Therefore, the channel requires frequent protection work, which, if neglected, can lead to flooding and leakage. On the other hand, it is very costly and time-consuming to reconstruct a new channel with concrete. Concrete canvas” is the solution to this problem.

Why repairing a deteriorated concrete channel is so difficult

表面が劣化したコンクリートは一般的に、水を抜いた後、上からコンクリートを塗りつけてヘラで均等にならします。これを左官仕上げと呼び、新たにコンクリート面作ったり、樹脂塗装や、樹脂版を貼り付けたりします。

また、劣化においては、表面以外にも、コンクリート同士の打ち継ぎ目に隙間ができて漏水が発生します。左官仕上げはあくまでも表面への対応なので、打ち継ぎ目に対しては有効ではありません。水路としての価値を保つためには、目地部分に上からテープを貼ったり、劣化がひどい場合には水路を一度取り壊し、作り直すことになります。

表面と目地の劣化は同時に発生するものの、別々の施工となりますので手配に負担がかかり、どうせならと水路を作り直す結論に至るケースが少なくありません。

ただし、「コンクリートキャンバス」という補修部材は、表面と目地の劣化に対して、同時に対応できます。施工も簡単かつ一度で済みますので劣化したコンクリート水路の補修に対して広く使われています。

What is "Concrete Canvas"?

Concrete Canvas” can build a brand new concrete channel on top of the current channel.

Easily build new channels over deteriorated channels

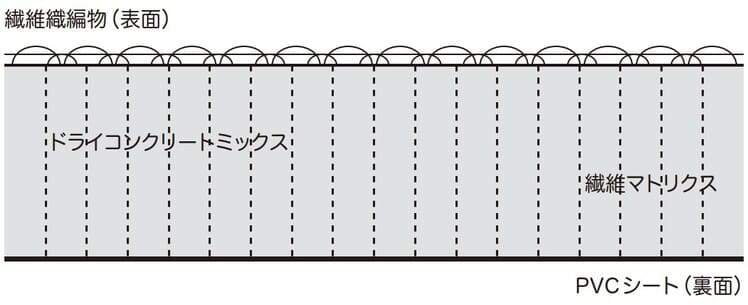

The composition of concrete canvas is a composite of “concrete” and “canvas (fabric)” that hardens when moisture is added. It combines the properties of fabric and concrete, and is a powerful solution for all open waterway works such as irrigation canals and spillways.

上述のように水路の表面と継ぎ目の補修に対して1度の施工で簡単に対応できるのは、施工性、耐久性、柔軟性という3つの大きな特長を持つからです。

まず施工性ですが、コンクリートキャンバスは1本で約70kg程度。現場での裁断も自在に行えるため、重機が入らないようなエリアでも人力で運搬・設置が可能です。そのため、プラントの設置や重機確保の手間とコストが削減されます。

In terms of durability, the product retains sufficient weather resistance to UV degradation. Weathering resistance tests conducted in accordance with British standards have confirmed that the product can withstand outdoor environments for at least 50 years.

And the concrete canvas has the properties of a fabric until it begins to harden, allowing it to follow the complex shape of the ground. It can be cut with a cutter knife, allowing for fine adjustments to suit the site. The flexibility of the concrete allows it to be used to cover waterways that vary in length, width, and direction.

Due to the above features, Concrete Canvas can easily construct a new concrete surface over a deteriorated existing channel. Since the thickness is very thin (5mm or 8mm), it does not significantly affect the cross-section of the channel. If a thicker layer were to be newly constructed, the U-shaped area inside the channel would be compressed, greatly reducing the amount of water that can flow through it, but this can be avoided.

Concrete Canvas Applications and Use Cases

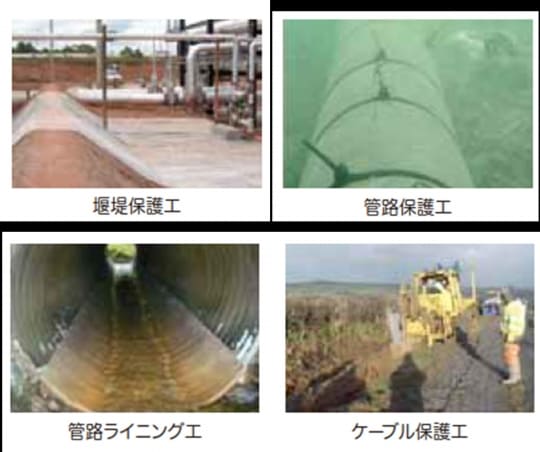

In addition to repairing existing waterways, concrete canvas is also a powerful tool in weir protection and conduit protection.

For example, in weir protection, concrete canvas is used to protect the banks installed to prevent oil leakage at oil facilities. In the case of conduit protection, resin pipes encasing optical fibers are protected by a hard concrete canvas to prevent them from cracking when stepped on. Its workability, durability, and flexibility make it useful not only for waterways, but also for all water-related construction work, protecting a wide variety of water facilities.

Concrete Canvas has already been adopted in all 47 prefectures in Japan, including the regular maintenance of a large training ground for the Self-Defense Forces in Hokkaido and municipal waterway construction in Shizuoka Prefecture. These are proof that Concrete Canvas has met the strict standards for adoption and is one of the proofs of its usefulness.

*Click here to see the results of Concrete Canvas (official website)

Concrete canvas is useful in temporary waterways

In addition, concrete canvas is an environmentally friendly material compared to cast-in-place concrete, and has the following three advantages: 1) it reduces CO2 emissions because it does not require large, heavy machinery, 2) there are no concrete spills during construction, and 3) it has low free alkali content.

summary

Concrete canvas is readily available at low cost, and its durability makes it a powerful tool for waterway construction. Please visit our official website to learn more about the various examples of our products being used by the Self-Defense Forces, local governments, and other organizations.

national land enterpriseへの

Contact us

Related Articles

- TOP>

- Taiyo Kogyo Column>

- Introduction of factors that cause concrete channels to deteriorate and easy and effective repair methods