Taiyo Kogyo Column

Insulation sheet that does not require a refrigerator │ Introduction of a cooling sheet that creates a cooling environment just by covering it from above

2017.11.22

「輸送する製菓や乳製品、生鮮品などを、客先で1~3時間、低温維持したい。そこまで厳しい保冷性能は求めてないないのに、『内容物のサイズが都度変わる』という条件があるが故に、希望に合致した保冷資材が見つからない。」これは温度管理が必要な商品を扱うあなたにとってお悩みの一つだと思います。

近年は、多様化する消費者の嗜好に合わせ、売り手も多品種小ロット生産にシフトする傾向にあります。しかし、業務用の保冷資材の多くは、箱型タイプで、保冷性能や価格には注力していますが、「柔軟な対応力」や「使い勝手」などを重視したものが少ないように感じます。

そこでこのブログでは、「手軽に使えて、内容物のサイズに応じた柔軟な対応が出来る」保冷資材をお探しのお客様向けに『クーリングシート』というシートタイプの保冷資材を紹介致します。

Cooling sheets are sheets with insulation properties useful for transporting contents that need to be kept cool, such as confectionery and milk. They look like silver blankets and are available in the following three standard sizes.

Cooling sheet standard size

- 2.3m x 2.3m

- 2.3m x 3.5m

- 3.4m x 4.5m

クーリングシートの一番の特徴は保冷したいもののうえから「被せるだけ」という手軽さにあります。 製菓や牛乳などの輸送業務では、小口配送時にバンなど商用車の荷台に乗せるケースがあります。クーリングシートはそのような冷蔵機能のない車でも、被せるだけで内容物の温度上昇を抑えられる作業負担の少ない温度管理ツールです。

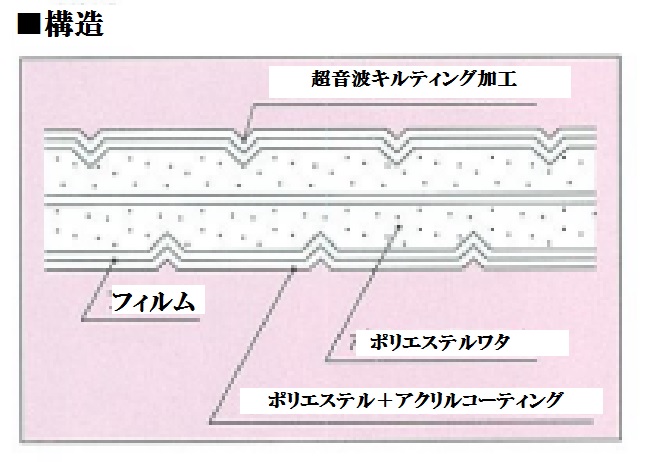

1-1. materials composing the cooling sheet and its thermal insulation effect

Cooling sheets are largely composed of a surface material and an inner material, each of which is as follows.

- Surface material: Polyester taffeta (acrylic coating)

- Inner material (insulation): polyester cotton (film coating)

クーリングシートは保冷品輸送現場での運用を想定し、「使い易い」、「繰り返し使用できる」ことに重点を置いた保冷資材です。

表面素材

The actual use of cooling sheets is in hectic transportation situations. In particular, the transportation of cool goods is a speedy process where time is of the essence and every second counts, so it is important to have the appropriate “strength” and “ease of use. Therefore, the cooling sheet is made of light and tough polyester taffeta. Even at sites with limited manpower, it can be used with peace of mind because it can be easily covered and will not tear with a little friction or load. The cooling sheet is also designed for use outdoors as well as indoors.

Looking at the actual photo of the Cooling Sheet, it looks as if it is sewn in a grid pattern. However, in consideration of waterproof property, the Cooling Sheet uses ultrasonic processing, which has no seam holes like sewing.

Furthermore, by applying an acrylic coating over the polyester taffeta surface material, the airtightness and water repellency are further enhanced. The water repellency prevents water leakage into the contents of the cooling sheet in the event of rain, etc., while the airtightness is an extremely important factor in keeping the contents cool. Temperature control through cold storage is

- Amount of energy from cold storage materials and other cold agents

- Insulation performance of insulation materials

- Airtightness of insulation

この3つの要素の大小で変化します。

クーリングシートは内容物の上から被せるという用途上、「3.断熱材の気密性」を上げることは難しいですが、シート自体の気密性を高めることで極力冷気を逃がしにくい仕様にしております。

屋外での温度管理の大敵は「日光」です。いくら断熱性の高い表面素材を使用していても、黒色など直射日光の熱を吸収しやすい色では、その効果も半減します。クーリングシートはシートの色味にシルバーを採用しています。シルバーは日光を反射し、温度上昇しにい色味になります。

内材(断熱材)

The insulation is made of light and soft polyester cotton for ease of use. It is very difficult to improve insulation performance while maintaining lightness and softness, but taking advantage of the fact that the more air layers there are, the higher the insulation performance, the cooling sheet has a six-layer structure with space.

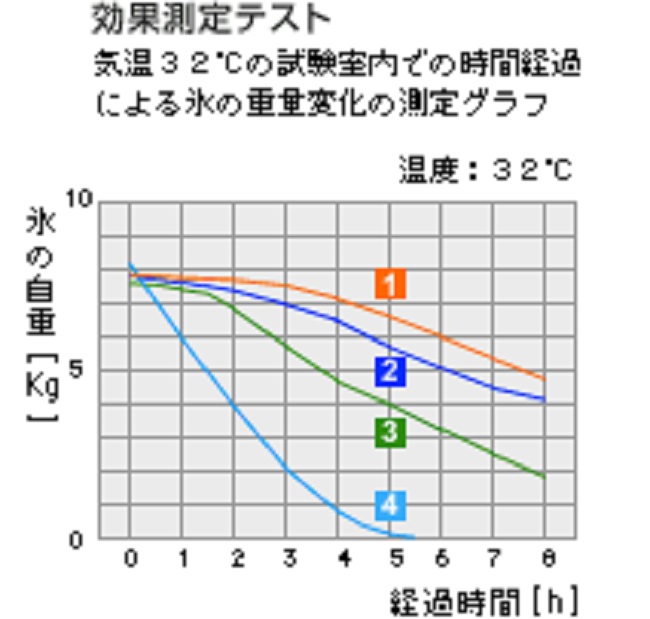

1-2. Cooling Sheet Performance

Please see the above graph. This is the measured melting time of ice weighing 8 kg under the condition of 32°C outside temperature. The conditions compared are as follows

- Result of covering with cooling sheet

- Result of covering with a similar cooling sheet of another company

- Result of covering with normal sheet

- Nothing covered.

Without any covering, the ice will melt in about 5 hours and 30 minutes. On the other hand, ice covered with a cooling sheet will still weigh about 6.5g (-1.5kg) after 5 hours. Comparing these results, -1.5kg ÷ -8kg = 0.18. In other words, just by covering the ice with the cooling sheet, we were able to slow down the melting speed of the ice by almost 80%.

1-3. main applications of cooling sheets

As I wrote in “1. What is a cooling sheet?” the most advantage of the cooling sheet is that it is easy to use, just by covering it with a sheet. If you are handling cold storage items that require strict temperature control, we recommend “commercial cold storage boxes,” but if you are focusing on the following, the cooling sheet is the perfect tool for your needs.

- Size of contents carried daily changes.

- We want to minimize the time spent on transportation of refrigerated goods.

- Strict temperature control is not required, but there is a need to slow the temperature rise of contents, such as temporary storage

Details are explained in “2-1. Easy-to-use, responsive cooling sheets”, but cooling sheets are used in the following applications.

- Milk delivery

- Ice and dry ice delivery

- Delivery of frozen and refrigerated foods

- Cold beer delivery

- As a cover for opening and closing the cold storage door

- As an energy-saving cover for showcases

- Cold transport by light van

It is used in a wide range of applications, including small-lot deliveries, of course, but also for adding extra cooling performance by covering items that originally had cooling performance, and for curtains to block cold air from cold storage by taking advantage of the characteristics of the sheet material, which is different from that of boxed items.

2. difference between cooling sheets and commercial cooling boxes

In the previous section, we have given an overview of cooling sheets. The question you may be asking yourself here is, “Which cooling sheet is the best choice for a commercial cold storage box? As it turns out, it depends on what you are looking for first. In the next section, we will compare cooling sheets and commercial cold storage boxes and look at the pros and cons of each.

2-1. Cooling sheet with excellent responsiveness

クーリングシートと業務用保冷ボックスの一番の違いはその「形状」にあります。見た目にも明らかですが、

クーリングシートはいわゆる「平物」であるのに対し、業務用保冷ボックスは「箱物」です。この形状の違いが現場での運用方法に大きな影響を与えます。

業務用保冷ボックスの場合、箱のなかに保冷が必要な内容物を入れて、蓋を締めるという運用になります。ここでポイントになるのが、箱のサイズや形は発注段階で固定されてしまうということです。これは同時に、中に入れることの出来る容積も固定されてしまうということです。毎日中に入れる内容物の量や形が一定の場合はこれで問題ありませんが、日々変わる商品を扱われる方にとっては、保冷ボックスのサイズに合わない商品を輸送する場合、そのボックスは役に立たないロストになってしまいます。

逆に平物であるクーリングシートはシートを被せるだけの運用ですので、保冷が必要な内容物のサイズや形が変わっても、柔軟に対応することができます。保冷ボックスのように保冷する内容物のサイズに応じて、複数サイズをストックし、いつも使わない保冷ボックスが倉庫で眠っているという無駄を省くことができます。

2-2. Cooling sheets are easy to work with.

業務用保冷ボックスは、その都度

「蓋を空ける→内容物を中に詰める→蓋を締める」

という作業があり、さらに、保冷ボックスの形に合わせ、内容物を隙間なく詰めるために作業する人は思考も働かせなければなりません。特に一度に複数個、保冷ボックスを使い配送する場合なら、かなりの工数になってしまいます。また繰り返し蓋を開け閉めすることで、蓋の気密性を補助するマジックテープやファスナーも劣化が進みます。

これに対し、クーリングシートは繰り返しになりますが、「被せるだけで保冷が出来る」という点で非常に作業性の高い保冷ツールです。

「内容物を置く→クーリングシートを被せる」

ただそれだけです。保冷する内容物の配置も深く考える必要はありませんし、開口部の劣化を気にする必要もありません。収納の際もクーリングシートは毛布を畳むような感覚で折りたたみ、収納ができるので手間も少なく保管場所もとりません。一方で保冷ボックスは折り畳み出来ないタイプだと保管に多くのスペースを必要とし、仮に折りたたみが出来るタイプであっても、折り畳み手間の少なさはクーリングシートには敵いません。

2-3. Cooling variations, loading and transportation aspects are weak points of cooling sheets

Although easy to use and easy to work with, cooling sheets are inferior to commercial cold storage bags (boxes) for the following applications.

- Cooling of contents requiring strict temperature control

- Contents required to be carried

2-3-1. What contents require strict temperature control?

- Contents that need to be managed in a negative temperature zone

- When it is necessary to maintain a constant cooling temperature for a long period of time

This refers to applications such as the following. Cooling sheet insulation is light and soft, and is very useful for the purpose of slowing the temperature rise of contents for a short period of time (1 or 2 hours), but to maintain cooling in the negative temperature range or to maintain a constant temperature for a long period of time, a better insulation material must be used. Materials with high insulation performance include expanded polystyrene foam and vacuum insulation. These are very hard insulation materials used for house walls, etc. This type of insulation is available for commercial cold storage boxes, but is difficult to use for cooling sheets. In addition to thermal insulation, “airtightness” is also very important to improve the cooling effect, but compared to commercial cooling boxes that are pre-processed into a box shape, cooling sheets that are simply placed over the object to be cooled are very weak in this respect. If you are considering cooling in the minus temperature range, please contact us for more information. The following is a brief description of the product. Cold chain logistics is optimized: ‼︎ High-performance commercial cold storage boxes (bags) using vacuum insulation”. for more information. If you are looking to maintain a constant temperature for an extended period of time, you may also want to consider our mechanical cold storage boxes ( Cool Cargo is suitable for maintaining a constant temperature for a long period of time. General commercial cold storage boxes keep the temperature low by putting cold storage materials inside the box, As described in the article “What should be confirmed when purchasing and using cold storage materials? As described in “What should be confirmed when purchasing and using cold storage materials”, cold storage material is a refrigerant that accumulates heat energy by being cooled in a freezer or other location in advance. Since the cooling effect weakens over time, it is difficult to maintain a strictly constant temperature for a long period of time. In contrast, COOL CARGO uses the same mechanism as a refrigerated/freezer truck, which uses electricity to deliver a constant amount of cold air to the inside of a storage unit, making it possible to maintain a constant temperature for a long period of time. Since COOL CARGO uses a different cooling system from the compressor type used in stationary refrigerators, it is resistant to shaking and can safely control temperatures even when transported in a passenger car.

For more information on COOL CARGO, please visit our blog What you need to know when buying and using COOL CARGO? for more information about COOL CARGO.

2-3-2. Contents required to be carried

When trucks are used to transport multiple deliveries of refrigerated goods, it is necessary to carry the goods from the truck parking area to the delivery location. For such applications, commercial refrigerated bags (boxes) with handles are more convenient than cooling sheets, as each box can be divided into smaller portions. In addition to being convenient to carry, the commercial cold storage bags (boxes) made of solid insulating materials such as expanded polystyrene foam can be stacked on top of each other to increase the volume that can be packed in one truck, thus improving transportation efficiency.

If you are considering the above applications, please contact us. If you are considering the above applications, please also see “Examples of Improvements in Commercial Cold Storage Boxes” for more details.

3. examples of cooling sheet applications

We hope that the previous contents have given you a good understanding of the basic performance and suitable applications of cooling sheets. In this chapter, we will introduce some examples of actual transportation of refrigerated goods using the cooling sheet.

3-1. use cooling sheets for temporary storage of confectionery

[Assignment].

これは、とある大手シュークリーム店の事例です。こちらは、カスタードクリームを工場で製造し、シュー生地にクリームを入れる作業は各店舗で行うことで、効率的に鮮度の高いシュークリームを製造・販売してらっしゃいます。ここで課題となったのが、輸送後のカスタードクリームをすぐに冷蔵庫に入れることが出来ないということでした。店舗での製造工程上、カスタードクリームが到着してから約1時間は冷蔵庫に保管場所が確保できず、店舗内の常温スペースに仮置きせざるを得なかったのです。 工場から店舗までの輸送時間は1時間程度と短く、カスタードクリームを入れた容器に蓄冷材を乗せておけば、問題無く輸送出来ます。また、店舗は大型デパートなどに併設されているため、仮に冷蔵庫に入れられなくても、常時空調が効いた、直射日光を気にしなくて済む環境下で仮置きできます。「店舗内の常温スペースで約1時間、冷蔵庫内と同じような保冷環境を作ること」 これをクリアするためにクーリングシートが活用されました。 このお客様の状況とニーズをまとめると以下のようになります。

Customer Situation and Needs

- The temperature difference between the desired cold storage temperature and the outside temperature is not high (storage of refrigerated goods in an air-conditioned room)

- Short-time cold storage (approx. 1 hour)

[Solution.

This one is quite simple.

- Transport from factory to store

- Temporary storage in store

Cooling by “cooling sheet + cold storage material” was implemented at both of these stages. Specifically, from the shipping stage at the factory, the container containing the custard cream was placed on top of the cooling storage material, and then covered with a cooling sheet to keep it cool. The same cooling process was also carried out at the temporary storage area after arrival at the store.

This only required more work to cover the container with a cooling sheet, but the cooling time of the cold-storage material was lengthened, making it possible to keep the container cool during temporary storage in the store. While minimizing the additional labor, the system solves a problem in the cooperation between the factory and the store. This is a typical example of utilizing the strength of the cooling sheet.

3-2. Set of styrofoam box and cooling sheet to enhance cooling effect

クーリングシートには他の保冷資材と組合わせ易いという特徴もあります。

既に発泡スチロールの箱による保冷輸送をされていれば、発泡スチロール箱の上からクーリングシートを被せて、保冷効果を高めることが出来ます。新規に更に保冷性能が高いボックスを買うとなると、コストも掛り、これまで使っていた箱の処分も困ります。ですがクーリングシートと併用すれば既存のボックスのまま、保冷輸送の時間を長くすることも可能です。

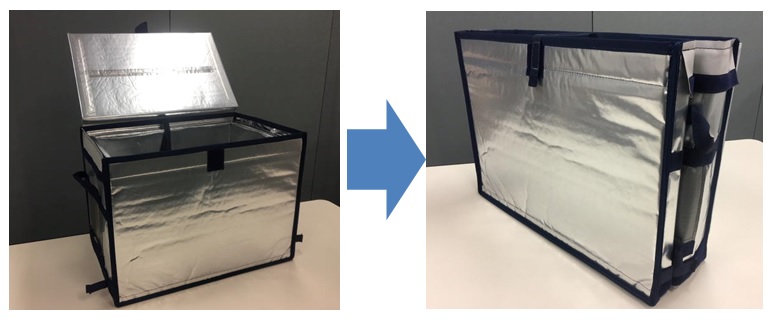

3-3.Cooling sheets are processed into non-box type cooling covers by order

クーリングシートはオーダーメイドで加工することが出来ます。「酒樽の保冷効果を高めたい」というニーズを例に説明していきます。業務用保冷ボックスをオーダーメイドした場合、サイズを酒樽に近づけることは出来ますが、湾曲した酒樽の形状にぴったり合わせた加工は難しいです。素材の硬さゆえ、どうしても角ばった形状になってしまうからです。

ですがクーリングシートであれば、素材の柔らかさを活かし、酒樽の形状にぴったり合う保冷カバーに加工することも出来ます。それ以外にも、冷蔵・冷凍トラックの冷気を遮断するカーテンなど用途に応じて幅広く対応できることがクーリングシートの強みでもあります。

Summary

The above has introduced the details of cooling sheet materials, their applications, and case studies. Again, the strengths of cooling sheet are

- Ease of use

- Flexibility of response

Specific uses include

- Reduces temperature rise of refrigerated products

- Combine with existing cold-retaining materials to increase cold-retaining effect

- Create a custom-made product that matches the shape of the item you want to keep cold.

There are some advantages such as the following. On the other hand, the weak points when compared to commercial cold storage bags (boxes) are

- Strict temperature control is difficult.

- Not suitable for carrying with cold products in it

This is the reason why we are here. Even if you understand the advantages of cooling sheets after reading this blog, it may be difficult to decide which to adopt, the commercial cooling box or the commercial cooling box. In such a case, the first point we would like you to consider is

- outside temperature

- Temperature you want to maintain within the cooling sheet

- Time to maintain temperature

- Space required (~ liters, etc.)

The four points are Please think about the ideal cold storage and transportation you desire after considering these points.

Logistics Businessへの

Contact us

Related Articles

- TOP>

- Taiyo Kogyo Column>

- Insulation sheet that does not require a refrigerator │ Introduction of a cooling sheet that creates a cooling environment just by covering it from above