Reinforced production system for “Medical Negative Pressure Tent” to meet domestic and overseas demand

~ Active in the fight against new strains of influenza and MERS, with overseas production under consideration in response to orders from both Japan and overseas~.

2020.03.06

March 6, 2020

(Tokyo headquarters: Setagaya-ku, Tokyo; Osaka headquarters: Yodogawa-ku, Osaka; President: Hidefumi Araki), a “membrane manufacturer” that handles large membrane surface structures (tent structures) and other products, has decided to speed up the supply of ” negative pressure tents for medical use, ” for which demand is increasing both in Japan and overseas due to measures against the new corona virus. As a first step, the company has begun to strengthen its production system, including domestic and overseas group factories, in order to manufacture 100 units by the end of April.

The “Negative Pressure Tent for Medical Use ” *1, for which we have decided to strengthen our production system, is a portable air tent that is equipped with a “negative pressure filter system ” *2 as standard equipment in the “McQuick Shelter,” which uses a patented inner bag type air tube (patented). By lowering the air pressure in the main tent, where medical procedures are performed, the air filters out viruses inside the tent, and only clean air is discharged outside, preventing the spread of viruses. Inside the main tent, air flow is maintained in a constant direction, creating an environment that prevents secondary infection among medical personnel.

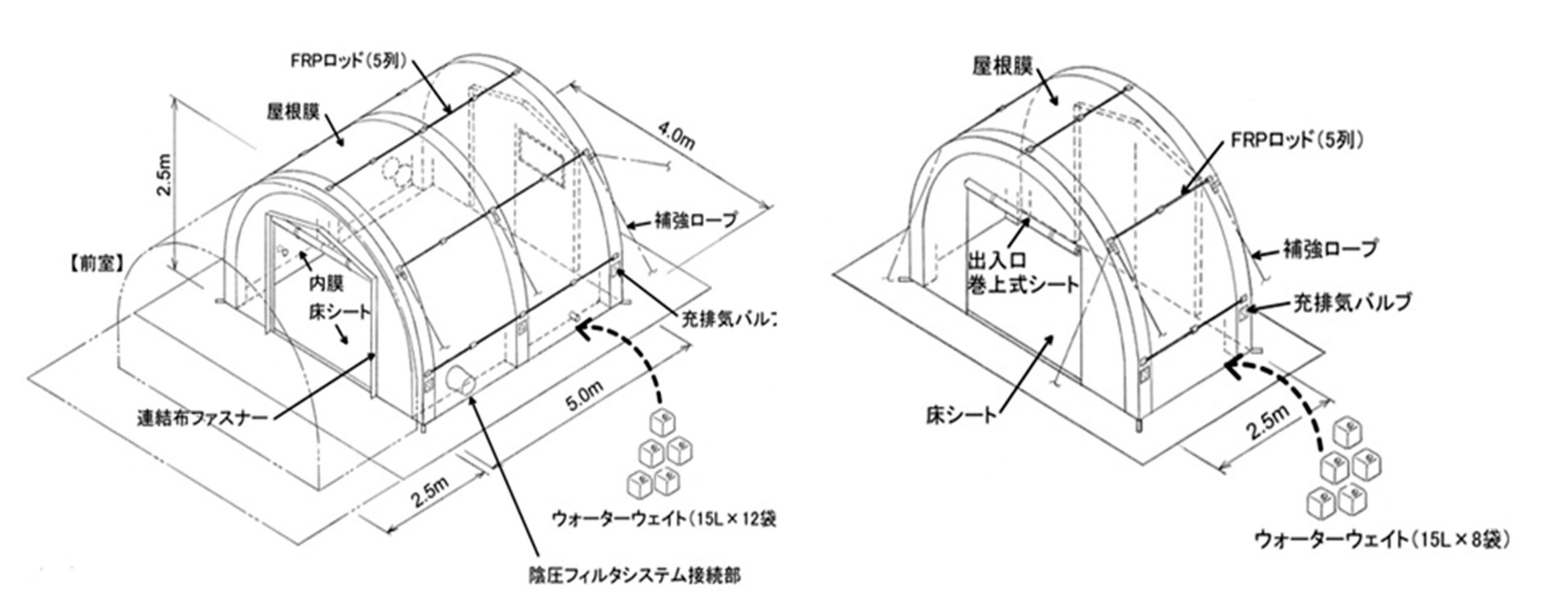

In addition to the main tent (4m wide x 5m deep x 2.5m high), we also offer various optional items such as a “front room” that functions as an airlock when entering the waiting room or the main tent, and an “air conditioning unit” to provide a comfortable environment for medical treatment in an emergency.

Since its launch in 2007, about 300 units of “Negative Pressure Tents for Medical Use” have been delivered to medical institutions in Japan and overseas as a countermeasure against the H1N1 influenza pandemic (2009) and the MERS pandemic that broke out in South Korea in 2015. Since its launch in 2007, about 300 units have been delivered to medical institutions in Japan and overseas as a countermeasure against the new influenza pandemic (2009) and the MERS epidemic in South Korea in 2015.

The standard version of the ” McQuick Shelter ” is also used in a wide range of applications, such as for disasters, events, and even as a countermeasure against extreme heat.

As the impact of the new coronavirus spreads both domestically and internationally, we have received numerous inquiries from the medical and welfare industries. We have already received orders from medical organizations in Asia and Japan, and although it is the busy season at the end of the fiscal year, we have decided that responding to the new coronavirus is a matter that requires prompt action.

Taiyo Kogyo has been producing “Medical Negative Pressure Tents” mainly at one factory, but plans to change to a system whereby production can be carried out at the factories of domestic and overseas group companies (8 domestic and 2 overseas factories). We hope to contribute to society by building a system that can respond quickly to urgent requests and flexibly meet the needs of medical facilities both in Japan and overseas.

*1: Standard equipment for the “Medical Negative Pressure Tent” includes the “MacQuick Shelter” itself, the “Negative Pressure Filter System” and “LED lighting”.

*2: This system is equipped with a HEPA filter and complies with CDC (Centers for Disease Control and Prevention) guidelines.

(technical) specification

| 1. size | Main body tent | Width 4m x Depth 5m x Height 2.5m |

| anterior chamber (of the eyes) | Width 4m x Depth 2.5m x Height 2.5m (optional) | |

| (Total) | Width 4m x Depth 7.5m x Height 2.5m | |

| 2. tent weight | Approx. 70kg | |

| anterior chamber (of the eyes) | Approx. 30 kg (option) | |

| (Total) | Approx. 100kg | |

| 3. time required to set up tent | Approx. 10 min. | |

| 4. membrane material | Polyester fiber cloth + vinyl chloride resin coating / Flameproof product | |

| 5. accessories | Negative pressure filter system, LED lighting, electric air pump (AC100V), 3-branch hose | |

| FRP rods (5 sets), standard accessory sets, etc. |

Price

3.2 million yen (excluding tax)

1,550,000 yen for the optional front room, 950,000 yen for the heating and cooling system, and 730,000 yen for the portable heater (all exclusive of tax)

Medical Negative Pressure Tent (with front room specification)

Interior view of main tent

conceptual diagram

Press photos can be downloaded here.

<For further information, please contact

Taiyo Kogyo Corporation https://www.taiyokogyo.co.jp/

Disaster Prevention Section, 2nd Sales Department, Land Infrastructure Projects Division: Kimoto, Hasegawa, Katsuno, Kajizawa Tel: 03-3714-3344

Or,

Corporate Communications (Public Relations): Ueda, Takatani, Nishikawa Tel: +81-6-6306-3033