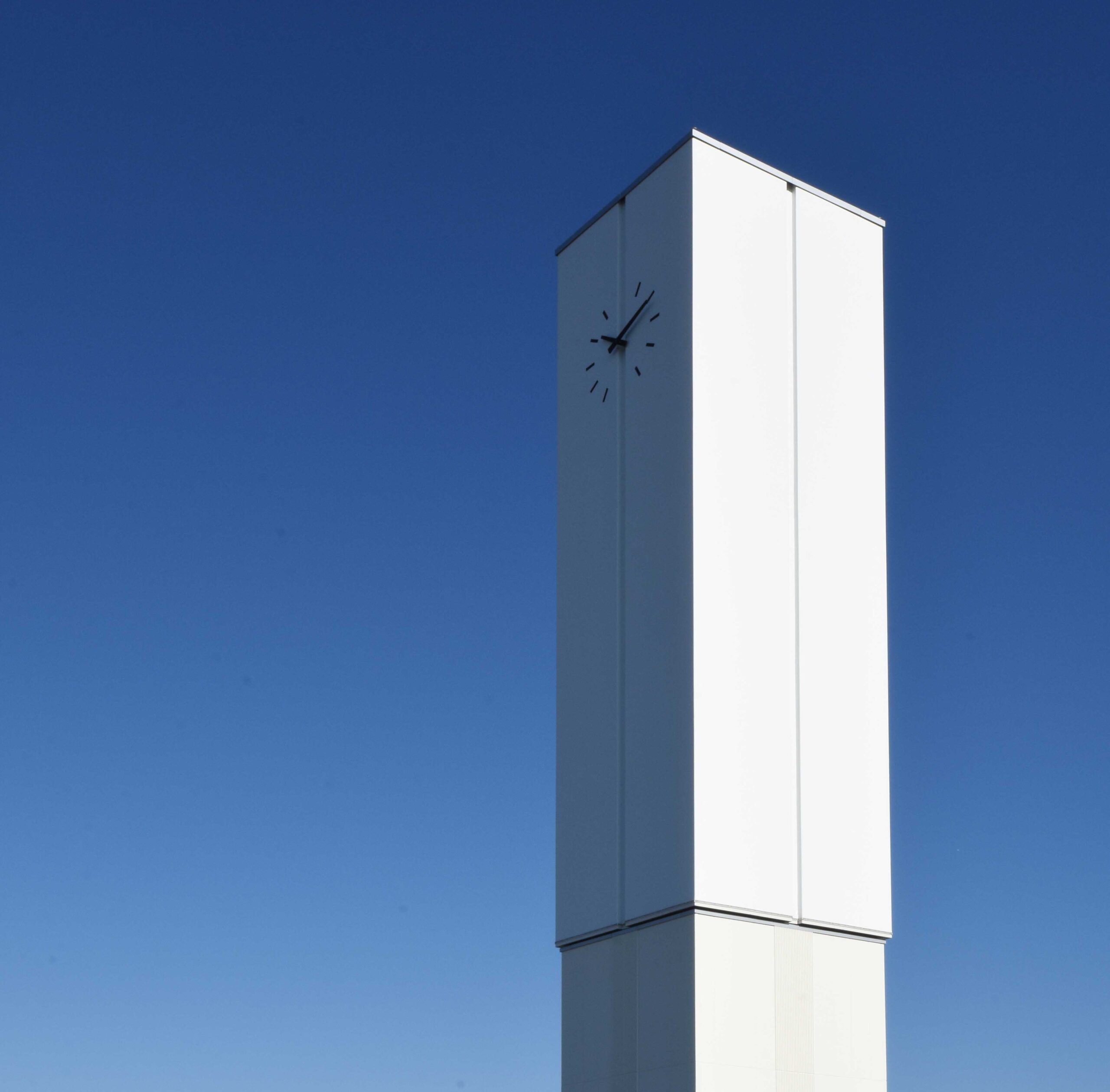

Completed the world’s first next-generation chimney

~Developed a chimney with a structure that is superior in design, earthquake resistance, and environmental friendliness

2018.06.21

(Headquarters: Yodogawa-ku, Osaka; President: Hidefumi Araki; hereinafter “Taiyo Kogyo”) and Hitachi Zosen Corporation (Headquarters: Suminoe-ku, Osaka; President: Takashi Tanisho; hereinafter “Hitachi Zosen”) have recently completed the world’s first “next-generation chimney” with superior design, earthquake resistance and reduced environmental impact. This chimney was applied at the Jonan Sanitation Management Association Clean Park Orii (located in Uji City, Kyoto Prefecture).

Overview of Next Generation Chimneys

「次世代煙突」は、従来のごみ焼却施設の煙突に用いられてきた外壁コンクリートやPCパネルに替わり、軽量素材である「フッ素樹脂酸化チタン光触媒膜材」を採用した新工法です。2011年に太陽工業と日立造船の共同で開発がスタートし、国土交通大臣指定性能評価機関である一般社団法人日本膜構造協会(東京都港区、菅原進一代表理事)の技術審査を経て、2013年より販売を開始しました。

1枚の膜パネルで大面積を覆うことができ、取り付け作業も内部から行うことで工期短縮を実現します。また、膜材を透過した光が煙突内部の空間に明るさをもたらしてメンテナンス時の作業性向上を実現し、さらには外壁塗装が不要なため、維持管理コストの低減にも繋がります。

Features of Next Generation Chimneys

[Design

The membrane structure allows for flexible shape design, and at night, LED illumination can be used for lighting to enrich the local landscape as a design tower.

Seismic resistance

The significant weight reduction due to the membrane material can improve earthquake resistance. The characteristics of the membrane material can follow the shaking during wind and earthquake.

Reduction of environmental impact

Nitrogen compounds (NOx) in the atmosphere are decomposed by titanium oxide photocatalytic membrane material. In this way, it not only purifies the surrounding environment, but also decomposes organic dirt and keeps it white with a self-cleaning effect that is washed away by rain.

Future Policies

The “next-generation chimney,” which uses a membrane structure for the chimney exterior wall, improves seismic resistance and workability, and its rich design features will lead to a renewed image of the adopted facility, enabling it to become a landmark in the community. Taiyo Kogyo and Hitachi Zosen intend to actively contribute to the realization of a safer and more attractive society through “next-generation chimneys.

About Taiyo Kogyo and Hitachi Zosen

As a manufacturer of large-scale membrane structural buildings, Taiyo Kogyo designs and constructs membrane structures for various fields and applications, including roof membranes for the Tokyo Dome (Bunkyo-ku, Tokyo) and Nagai Athletic Stadium (Higashi Sumiyoshi-ku, Osaka) in Japan, as well as large-scale sports facilities overseas.

Hitachi Zosen has delivered more than 400 reinforced concrete and steel chimneys to municipal waste incineration and power generation facilities and thermal power plants, and has top-level experience and technology in chimney design, fabrication, and construction in Japan.

Construction status of the next generation chimney