Pallet management system

Individual pallet management greatly streamlines logistics management

Integrated palletization is an effective means of improving logistics efficiency. However, if pallets are not collected and managed properly, they may be lost or misplaced, resulting in significant cost increases.

*What is consistent palletization?

A method of transportation in which cargo is placed on a single pallet and transported to its destination. “A forklift can be used for transshipment. “A forklift can be used for transshipment,” and “the time and labor required to change pallets can be eliminated. The pallets can be used for transshipment, and the pallets can be reloaded without the need to change pallets, etc.

*For sale only in the Japanese market

Related Keywords

Product & Service

Strong support for your company's logistics management

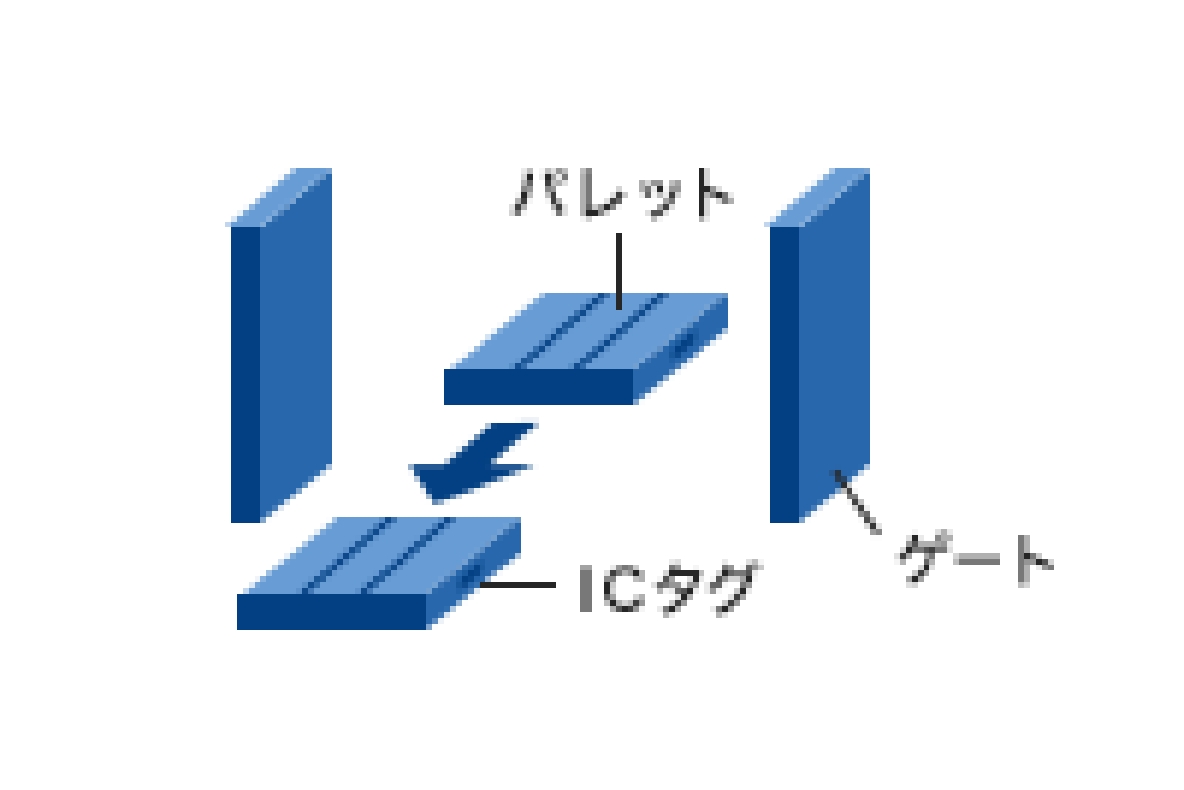

Individual RFID management

RFID (micro wireless IC chip) is used to obtain information on each pallet, enabling individual pallet management.

Prevents pallets from being lost or misplaced

By attaching ID tags with individual IDs, it is possible to manage when and where each pallet is rented out.

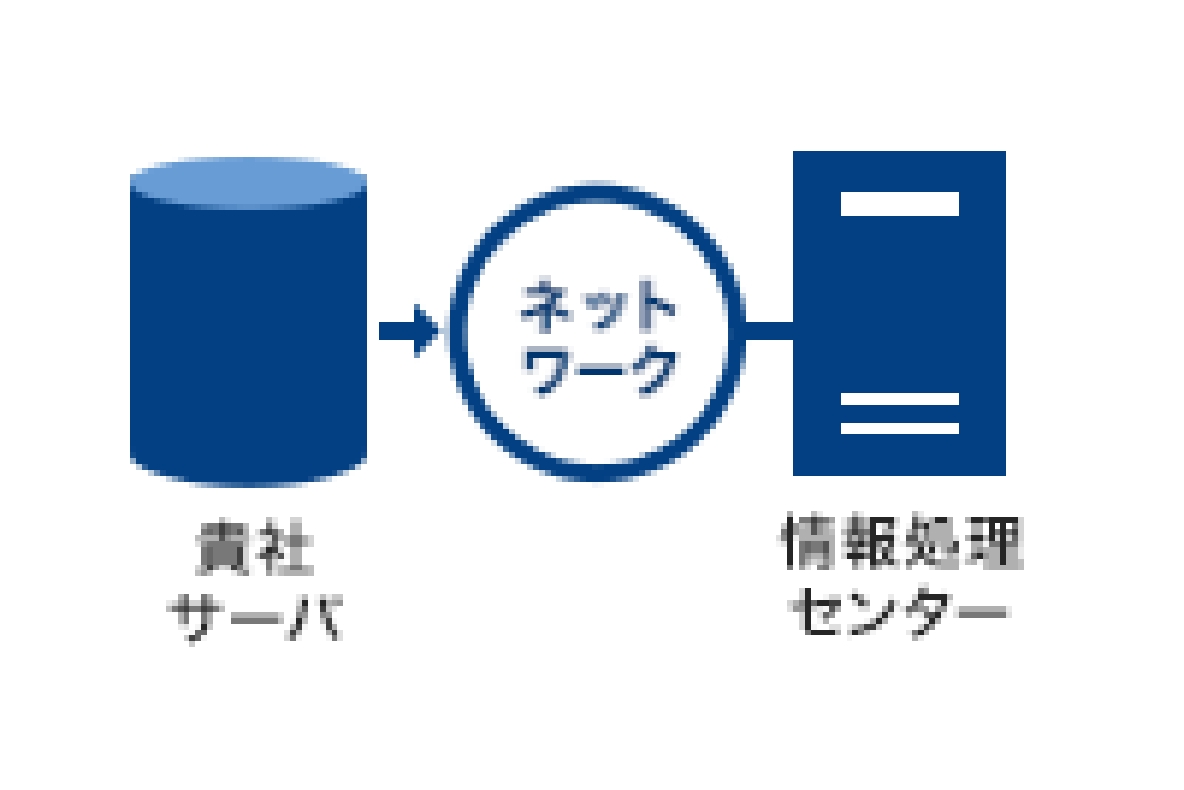

TDS Information Processing Center provides meticulous pallet management.

What is RFID (Radio Frequency Identification)?

This technology uses IC tags to exchange information via wireless communication. By attaching the tags to pallets, it is possible to obtain individual information on each pallet.

Pallet management system flow

STEP1 Information reading

By passing through the gate, the information on the IC tag attached to the pallet is read. Unlike barcodes, multiple pallets can be read simultaneously.

STEP2 Data transfer and storage

The read information is once stored on a server. The information is automatically transferred to the database of the information processing center through the network.

STEP3 Web browsing and output

Information stored in the database is processed into various forms. The processed forms can be viewed and output from the customer’s PC via the Internet.