”Gundle Sheet LD Series”

-Low destiny polyethylene sheet-

Polyethylene sheet with both flexibility and strength

This is an impervious sheet made of low-density polyethylene material that combines the excellent physical properties and softness of polyethylene sheet. It falls under the medium elasticity type in the classification of the Japan Lining Systems and Technologies Association.

Related Achievements

Product & Service

Product Lineup

Gundle Sheet LDA

This low-density polyethylene sheet is highly flexible while retaining the excellent physical properties characteristic of polyethylene. The wide width of more than 6 m enables shortening of the construction period while ensuring the quality of construction.

Gundle Sheet LDM

This is a low-density polyethylene sheet polymerized using a metallocene catalyst. In addition to the features of polyethylene sheet, such as excellent chemical resistance, weather resistance, and tensile strength, it has a uniform molecular distribution, is extremely flexible, and has excellent melting properties.

Method of joining impervious sheets

Self-propelled welding situation

Self-propelled fusion bonding machines are mainly used to fuse impervious sheets. Pressure is applied while the sheets are heated by a hot plate or hot air to unify overlapping sheets.

Pressure test status

The watertightness of the joint is inspected by applying pressure to a predetermined value through the inspection hole in the center of two rows of joints (double seam method) and measuring the amount of pressure reduction.

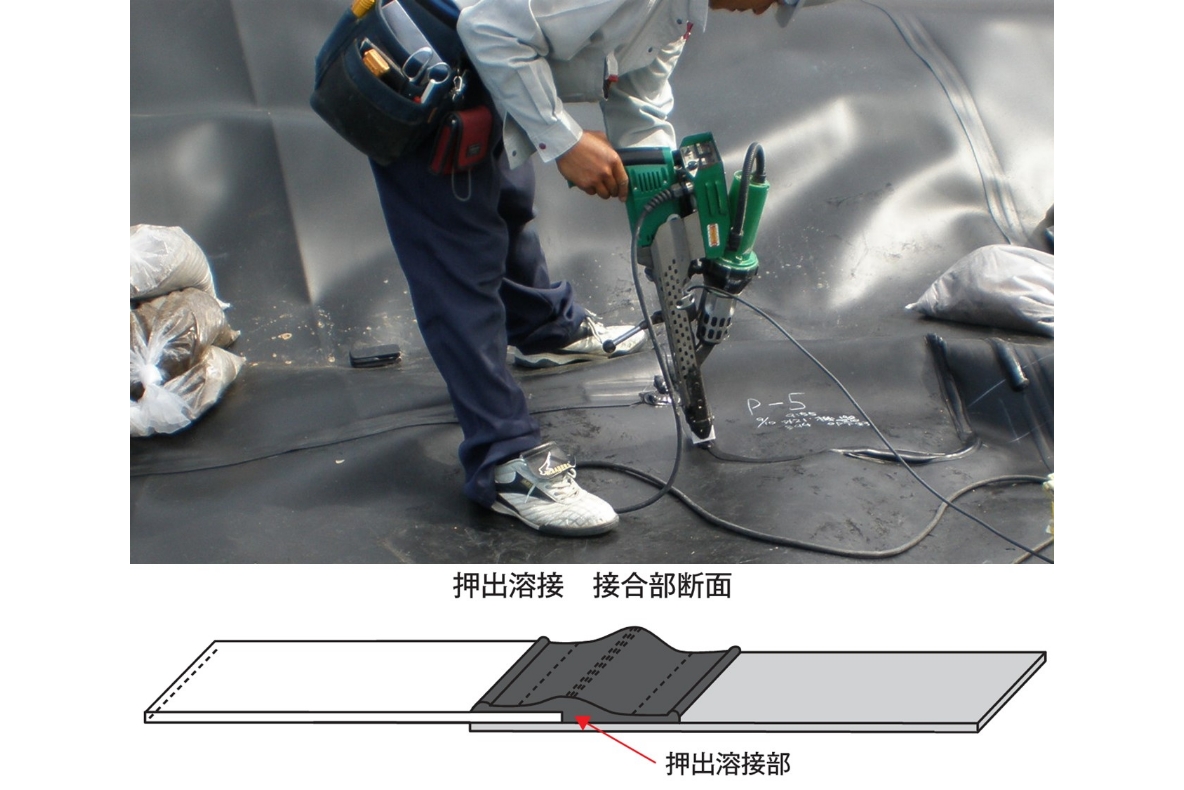

Extrusion welding status

Extrusion welding is used for joints that are difficult to install with a self-propelled fusion splicer. Using a dedicated welding machine, cuttings of the same material as the impervious sheet are melted and integrated with the sheet.

standard value

| item | Low elasticity type | Medium elastic type | High elasticity type | Test procedure | |

|---|---|---|---|---|---|

| Thickness (mm) | 1.5 | 1.5 | 1.5 | JIS K 6250 compliant | |

| Tensile performance | Tensile strength (N/cm or more) | 120 | 140 | 350 | JIS K 6251 compliant |

| Growth rate (% or more) | 280 | 400 | 560 | ||

| Tear performance | Tearing strength (N min.) | 40 | 70 | 140 | JIS K 6252 compliant |

| Joint Strength Performance | Tear performance | 60 | 80 | 160 | JIS K 6008 compliant |

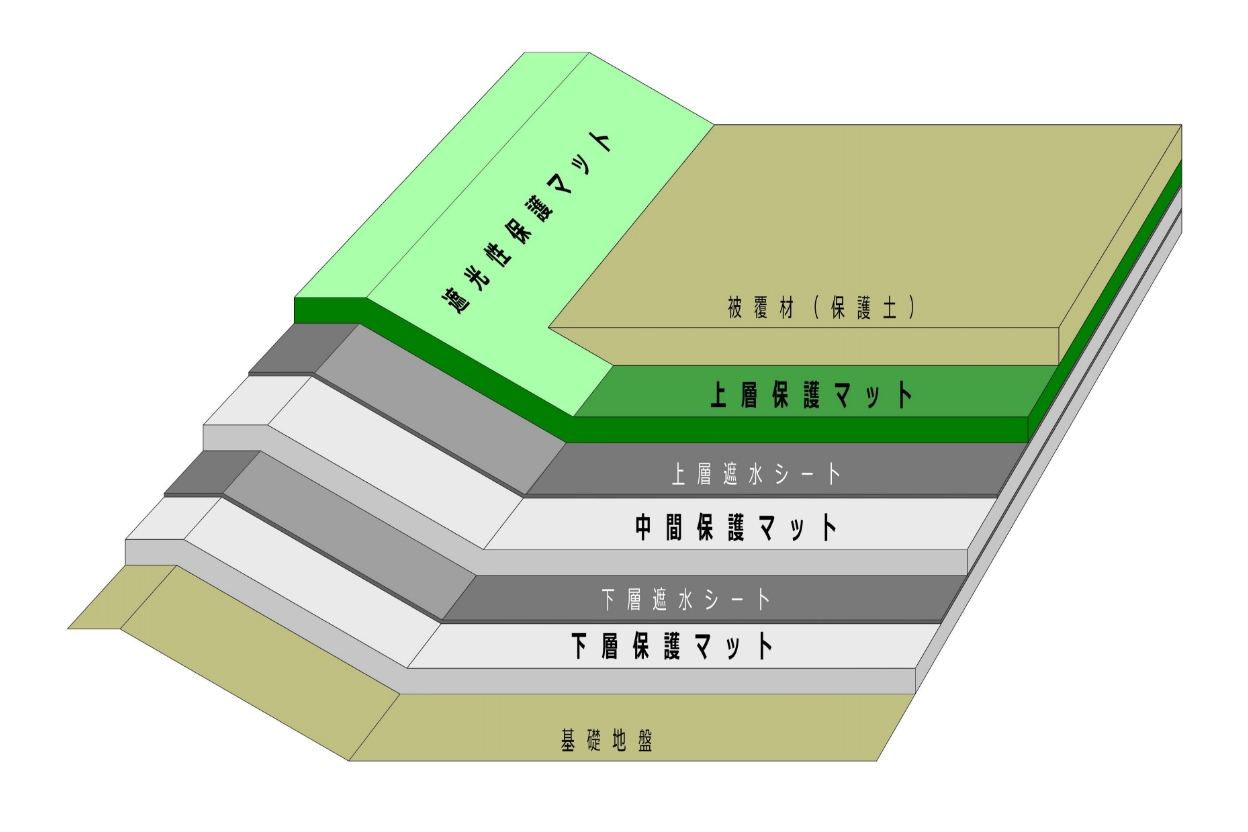

Usage

- Landfill

- Closed final disposal site

- Contaminated soil containment

- Capping