"Gundle Sheet HD"

-High Density Polyethylene sheet-

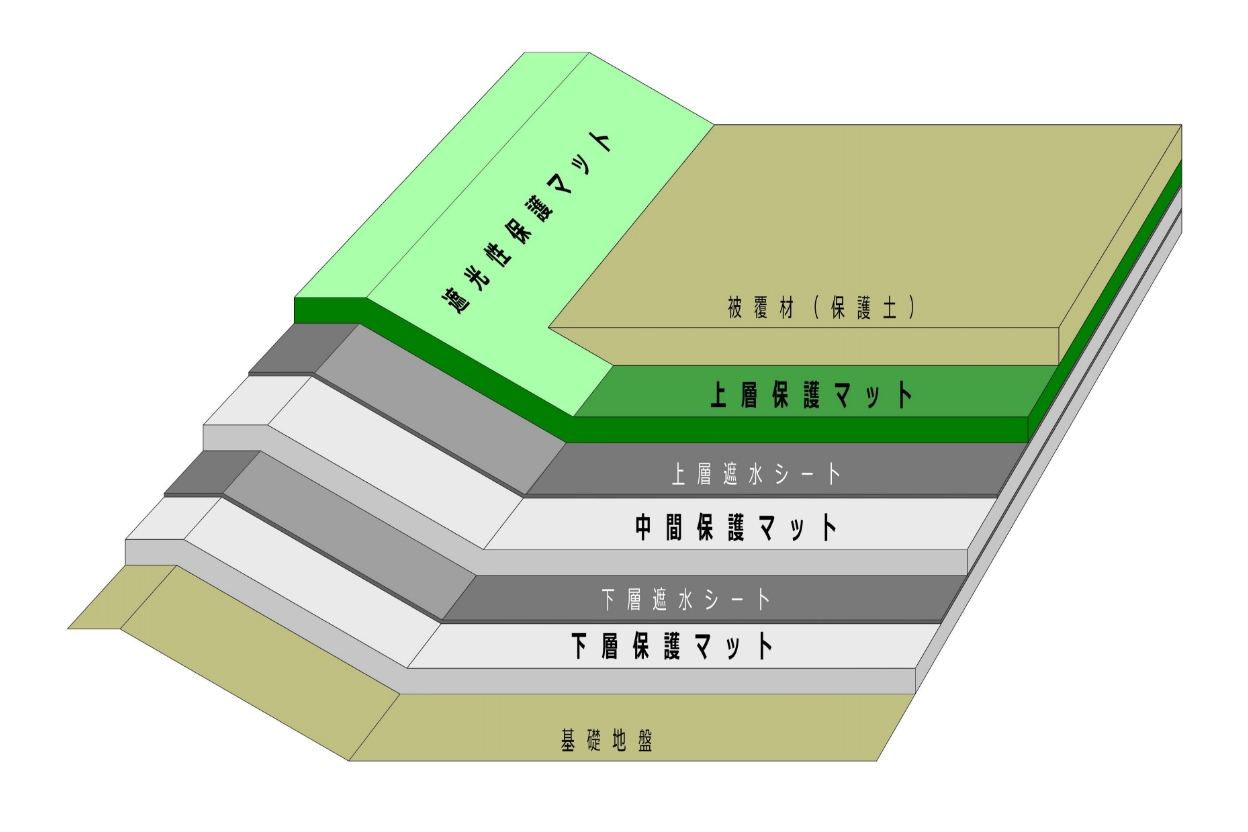

Standard for final disposal sites

High-density polyethylene sheet

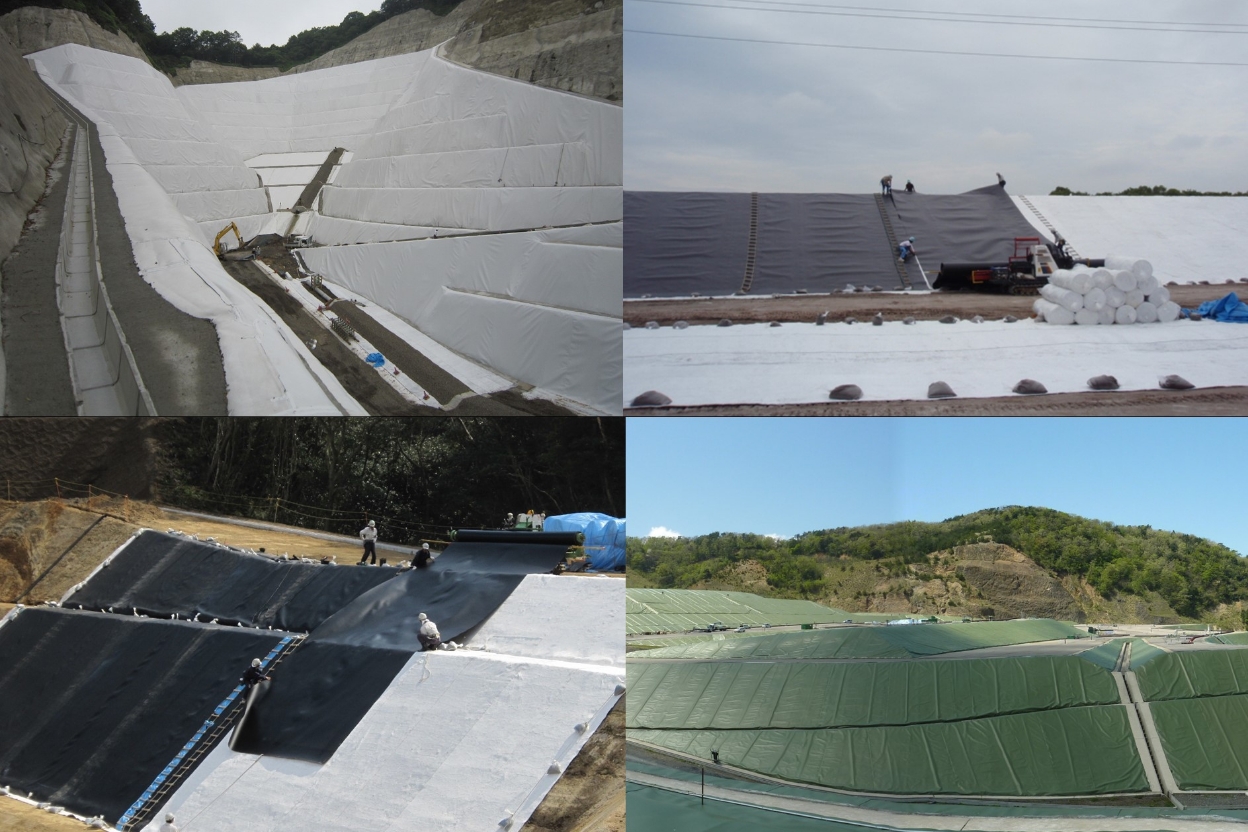

A global standard impervious sheet that has been installed in 50 countries around the world for a variety of applications including final waste disposal sites, reservoirs, and detention ponds, with excellent physical properties such as tensile strength and chemical resistance. It is classified as a high elasticity type by the Japan Lining Systems and Technologies Association.

Related Achievements

Product & Service

Product Lineup

Gundle Sheet HD

This is the most standard high-density polyethylene (HDPE) sheet. HDPE has excellent tensile strength and chemical resistance, and is highly elastic (spring-like in its ability to return to its original shape when force is applied). Its wide width reduces on-site joints, contributing to quality and construction time.

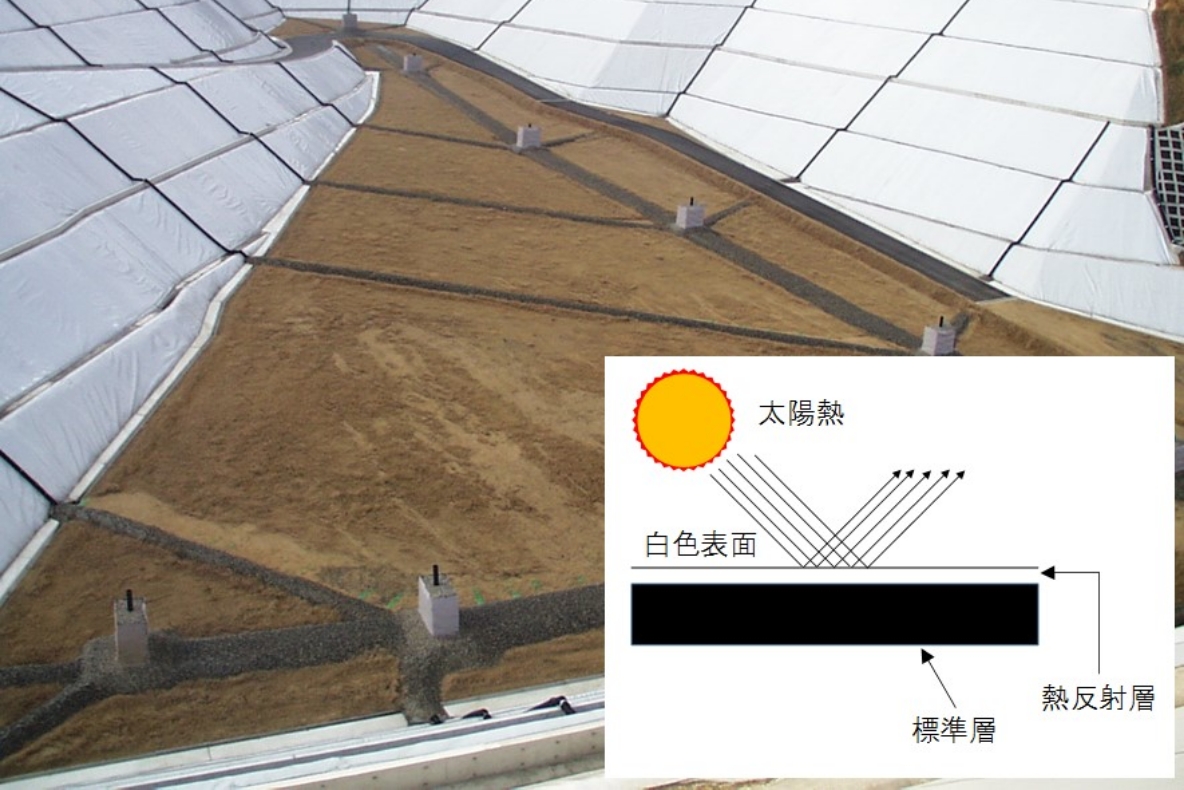

Gundle Sheet HDW

This is a high-density polyethylene (HDPE) sheet with a white layer on the surface. The white layer reflects sunlight and prevents the sheet from rising in temperature, thereby reducing expansion and contraction of the sheet due to temperature changes. The white layer also makes it easier to see minor damage.

Gundle Sheet HDCW

The most important factor in constructing a leak-free impervious sheet is a reliable watertightness inspection. The Gundel Sheet HDC Series has a conductive layer on the reverse side, which enables damage to be checked by a spark inspection machine. It is possible to electrically inspect for damage in areas where watertightness inspections have been difficult in the past.

Gundle Sheet HDF

This is a “high-friction (rough surface) sheet” with polyethylene particles dispersed on the surface of the high-density polyethylene sheet to create a “rough” surface. In areas where overburden loads are generated, if the interlayer frictional resistance of the impervious layer is low, tension is generated in the impervious sheet. In such locations, the use of “high friction type (rough surface) sheets” can reduce the stress on the impervious sheets by increasing the frictional resistance between the impervious layers.

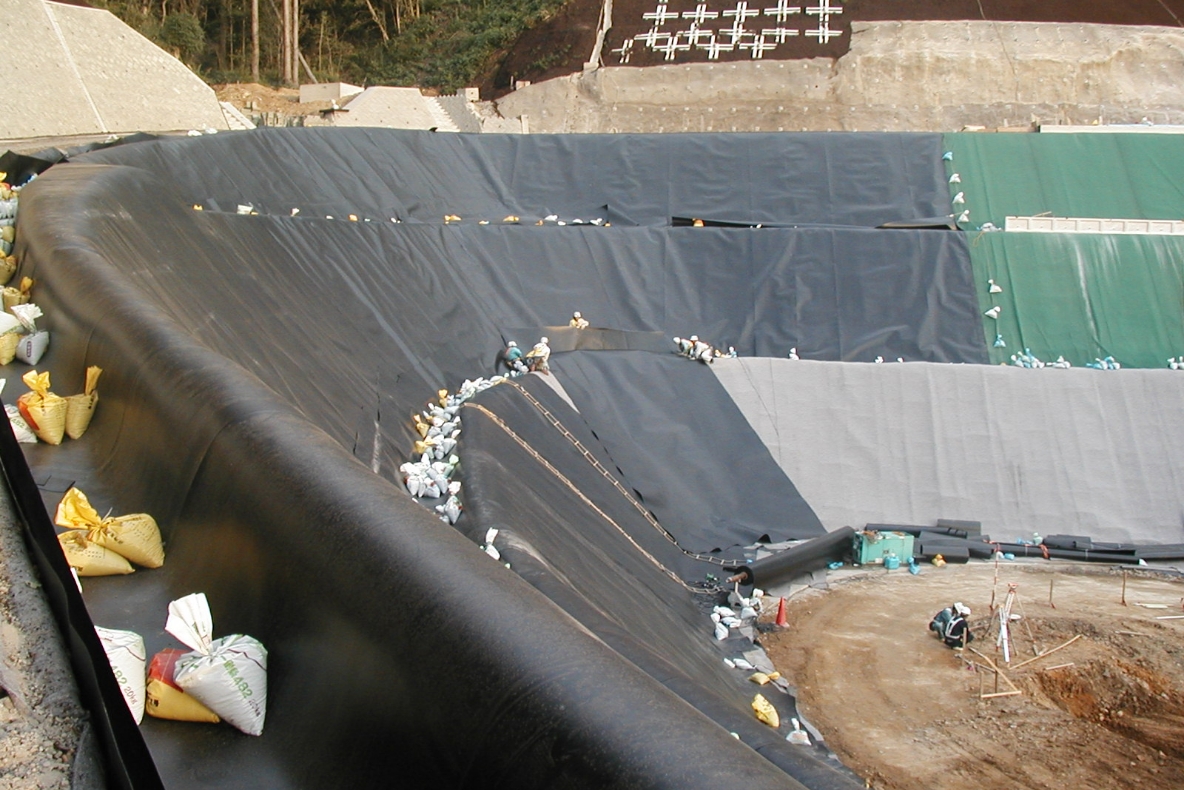

Method of joining impervious sheets

Self-propelled welding situation

Self-propelled fusion bonding machines are mainly used to fuse impervious sheets. Pressure is applied while the sheets are heated by a hot plate or hot air to unify overlapping sheets.

Pressure test status

The watertightness of the joint is inspected by applying pressure to a predetermined value through the inspection hole in the center of two rows of joints (double seam method) and measuring the amount of pressure reduction.

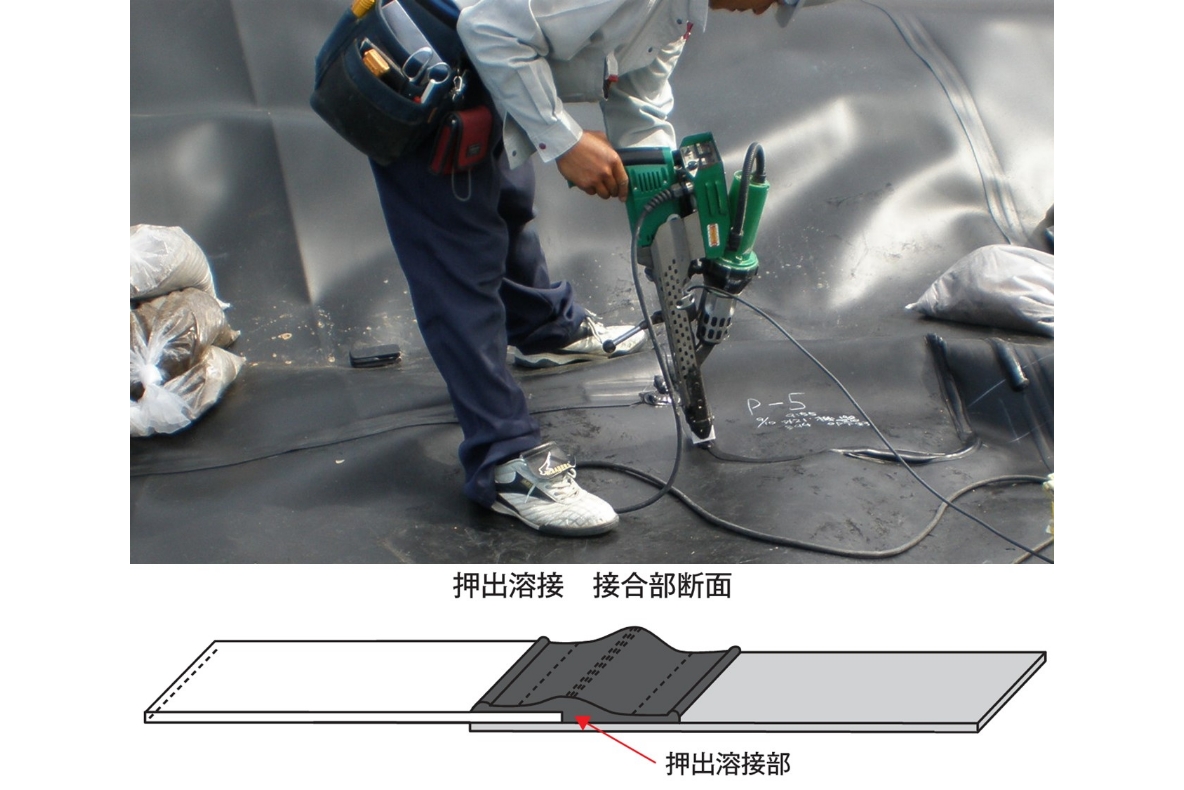

Extrusion welding status

Extrusion welding is used for joints that are difficult to install with a self-propelled fusion splicer. Using a dedicated welding machine, cuttings of the same material as the impervious sheet are melted and integrated with the sheet.

standard value

| item | Low elasticity type | Medium elastic type | High elasticity type | Test procedure | |

|---|---|---|---|---|---|

| Thickness (mm) | 1.5 | 1.5 | 1.5 | JIS K 6250 compliant | |

| Tensile performance | Tensile strength (N/cm or more) | 120 | 140 | 350 | JIS K 6251 compliant |

| Growth rate (% or more) | 280 | 400 | 560 | ||

| Tear performance | Tearing strength (N min.) | 40 | 70 | 140 | JIS K 6252 compliant |

| Joint Strength Performance | Tear performance | 60 | 80 | 160 | JIS K 6008 compliant |

Usage

- Landfill

- Closed final disposal site

- Contaminated soil containment

- Capping