"Max Drain"

-Mesh flexible culvert drainage pipe-

This culvert drainage pipe has a number of features, including ideal culvert drainage pipe and resistance to clogging.

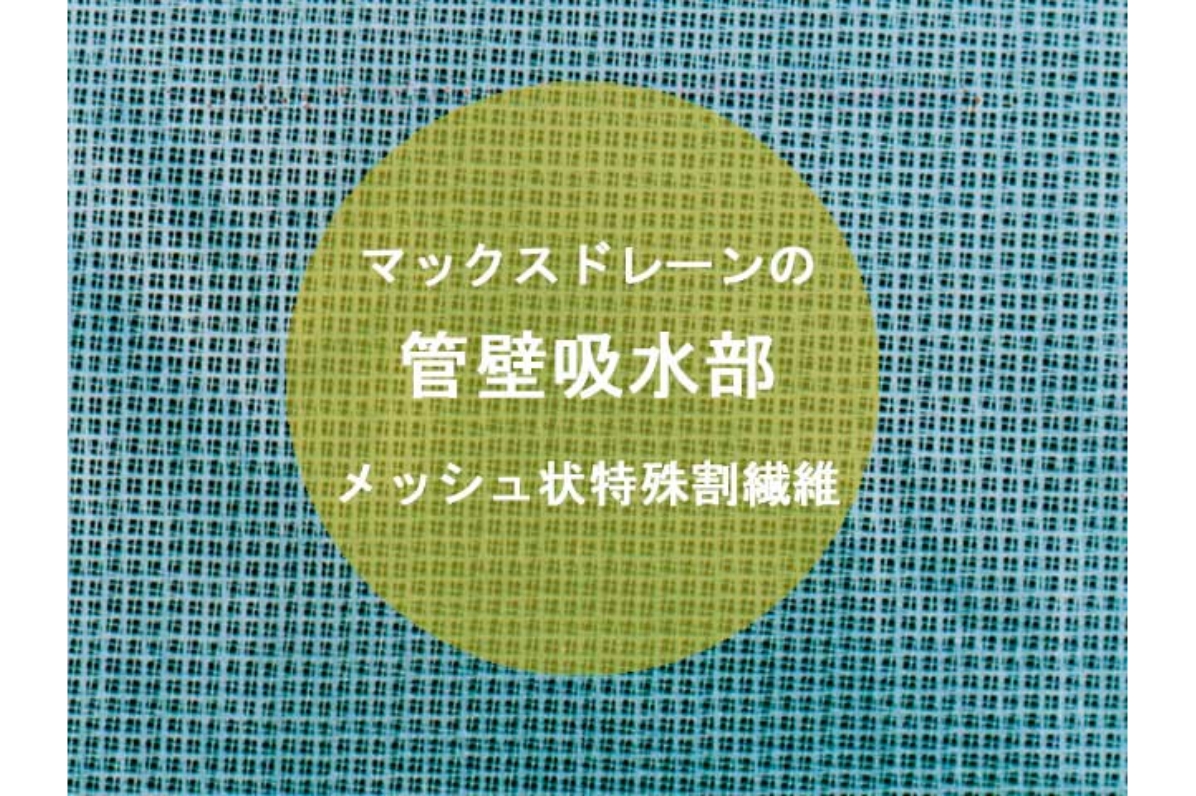

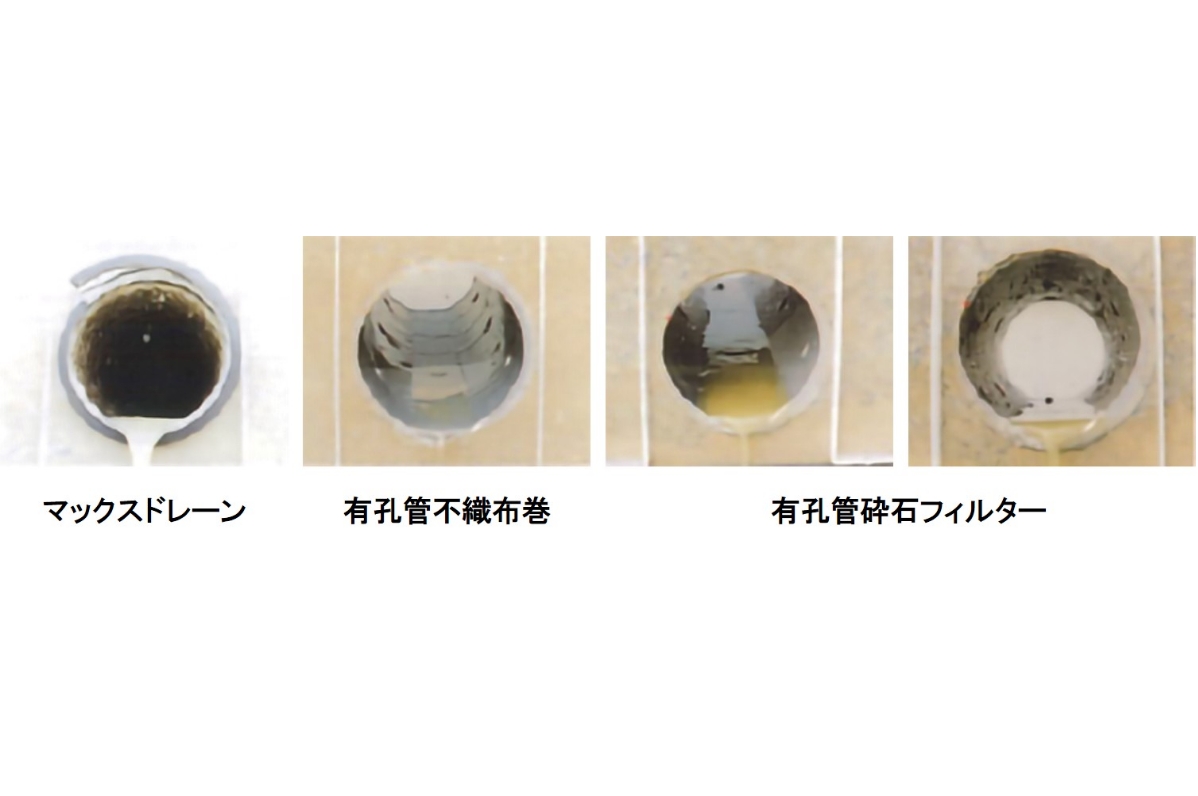

Two layers of special mesh-like split fibers prevent the inflow of sand, and the silt that can flow out with the seepage water can flow out without being stopped by the pipe wall, thus preventing clogging due to the formation of an impervious layer.

*For sale only in the Japanese market.

Related Achievements

Product & Service

Feature

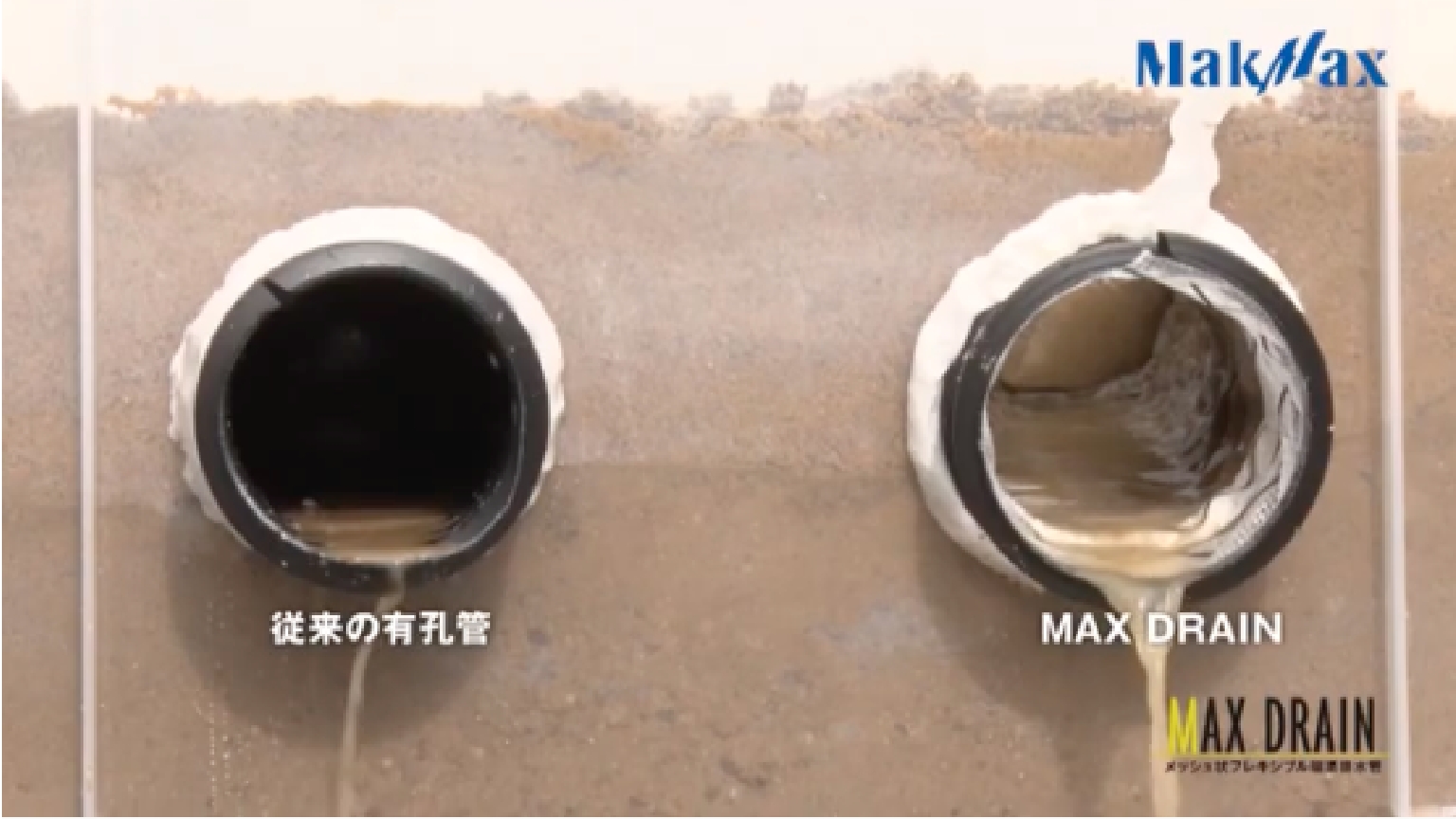

Resistant to clogging

Since each water absorption hole is of moderate size (around 0.2 mm), there is no withdrawal of fine sediment, and silt content does not adhere to the pipe wall but flows out with seepage water, preventing clogging caused by the formation of an impervious layer.

Large water supply capacity

The water collection pore area per unit area is extremely large at around 22%, and the most important individual pore diameter is not too small at around 0.2 mm, so the high water absorption capacity is sustained.

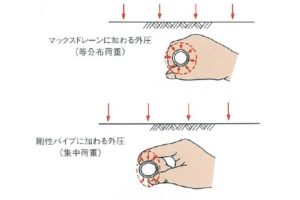

High external pressure strength

The flexible and tamper-resistant pipe is not subjected to concentrated loads in the soil, and the load is equally distributed, resulting in a strong external pressure resistance.

Good workability

TM-100 One (20m) piece weighs only about 9 kg, making it easy to transport and lay, and economical to install.

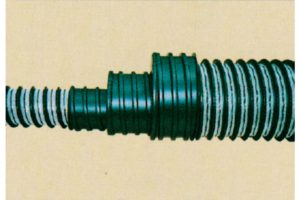

Flexible and long

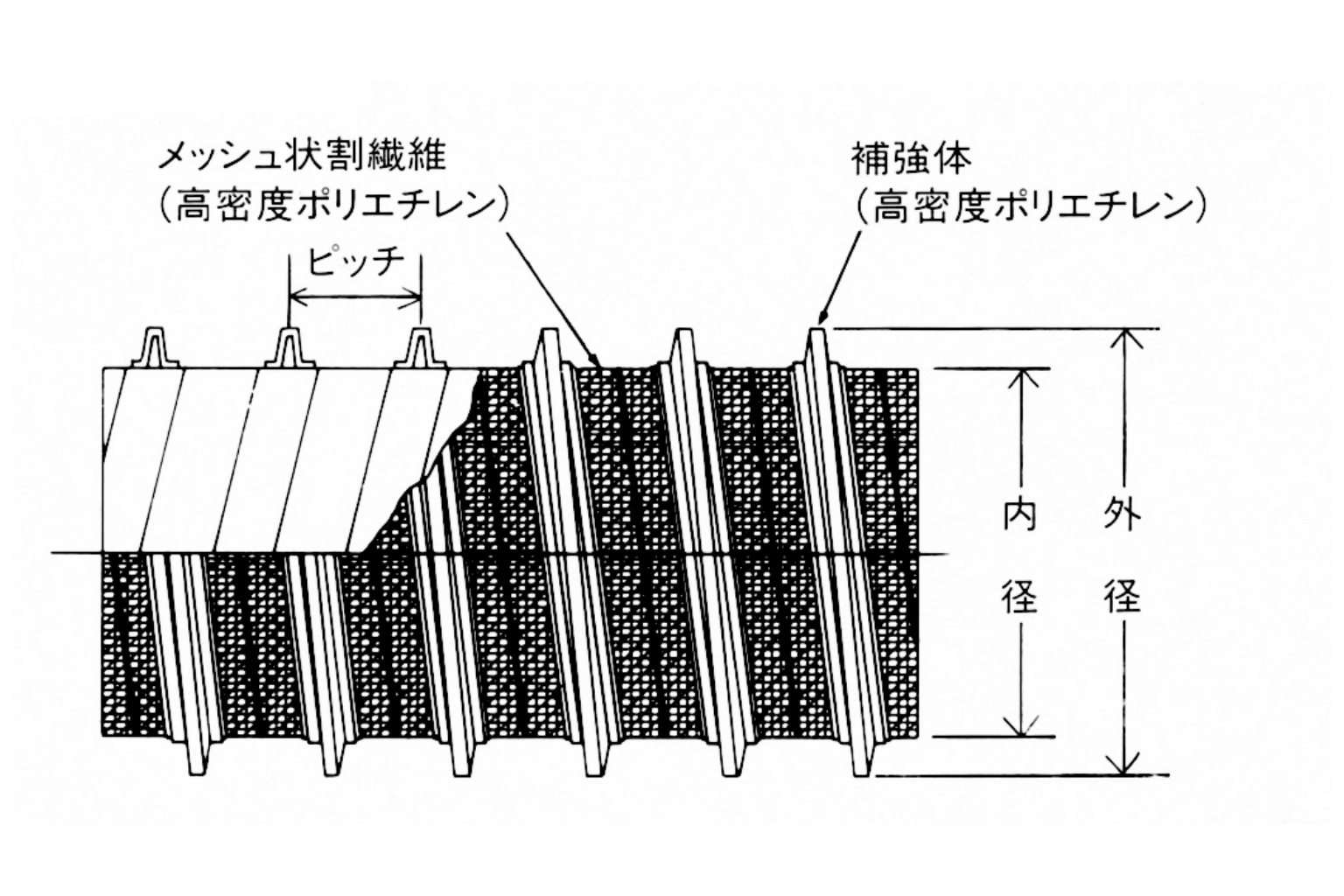

A flexible, long seepage pipe with a special split-fiber tubular body and lacen-like reinforcement fused to it, which can be easily installed in curves and can follow unequal settlements.

High external pressure strength

Design example Allowable deformation rate [Design conditions] Protrusion-type inverted protrusion pipe burial (refers to the case where the pipe is laid in a shallow excavation trench and the fill is placed over it) Track load: 25t, unit volume weight of soil: 18kN/m3 (1. 8tf/3 ), soil cover: 0.2 to 50m, backfill material: No. 3 to 5 crushed stone, compacted soil: normal condition E ‘=13. 72×103kN/m2(140kg/cm2 )8% or less)

| designation | ||||||

|---|---|---|---|---|---|---|

| Soil cover (m) | TM-50 | TM-75 | TM-100 | TM-150 | TM-200 | TM-300 |

| 0.2 | 5.4 | 5.4 | 5.6 | 5.8 | 5.9 | 5.9 |

| 0.3 | 4.1 | 4.1 | 4.3 | 4.4 | 4.5 | 4.5 |

| 0.6 | 2.3 | 2.3 | 2.5 | 2.6 | 2.6 | 2.6 |

| 0.8 | 1.8 | 1.8 | 1.9 | 2.0 | 2.0 | 2.1 |

| 1.0 | 1.5 | 1.5 | 1.5 | 1.6 | 1.7 | 1.7 |

| 2.0 | 1.2 | 1.2 | 1.2 | 1.3 | 1.4 | 1.5 |

| 4.0 | 1.3 | 1.3 | 1.4 | 1.5 | 1.6 | 1.7 |

| 6.0 | 0.9 | 0.9 | 0.9 | 1.0 | 1.0 | 1.1 |

| 8.0 | 1.1 | 1.1 | 1.1 | 1.2 | 1.2 | 1.3 |

| 10.0 | 1.3 | 1.3 | 1.4 | 1.4 | 1.4 | 1.5 |

| 20.0 | 2.5 | 2.5 | 2.6 | 2.6 | 2.7 | 2.7 |

| 30.0 | 3.7 | 3.7 | 3.8 | 3.9 | 3.9 | 4.0 |

| 40.0 | 4.9 | 4.8 | 5.0 | 5.1 | 5.1 | 5.2 |

| 50.0 | 6.0 | 6.0 | 6.2 | 6.3 | 6.4 | 6.5 |

Main components and installation procedures

Straight pipe connection

After screwing a straight pipe fitting all the way into one end of the Max Drain, butt the other end to be connected, and connect by turning the straight pipe fitting backwards.

Odd-diameter straight pipe connection

Connect using a Reducer.

T-junction, cross pipe connection

The T-junction/cross-junction body can be connected to the Max Drain via a straight pipe or a regulator.

Connecting parts

T-shape/cross combination type

| designation | TM-50 | TM-75 | TM-100 | TM-150 | TM-200 | TM-300 |

|---|---|---|---|---|---|---|

| TM-50 | Fat. | Fat. | Fat. | Fat. | weak | weak |

| TM-75 | Fat. | Fat. | Fat. | Fat. | weak | weak |

| TM-100 | Fat. | Fat. | Fat. | Fat. | Fat. | Fat. |

| TM-150 | Fat. | Fat. | Fat. | Fat. | Fat. | Fat. |

| TM-200 | weak | weak | Fat. | Fat. | Fat. | Fat. |

| TM-300 | weak | weak | Fat. | Fat. | Fat. | Fat. |

Type/Standard

| type | Outer diameter (mm) | Inside diameter (mm) | Pitch (mm) | fixed length (e.g. block) |

|---|---|---|---|---|

| TM-50 | 64 | 52 | 30 | 20m per piece (with threaded straight-through coupling) |

| TM-75 | 91 | 75 | 35 | |

| TM-100 | 121 | 103 | 35 | |

| TM-150 | 169 | 150 | 35 | |

| TM-200 | 227 | 203 | 35 | |

| TM-300 | 330 | 298 | 35 | 1 piece, 5 m (with threaded straight-sugar joint) |