Frame Tent

This is a "domestic" high-strength, aluminum alloy frame tent that can be easily assembled by a small number of people.

Frame Tents are “domestically made” tents ideal for medium- to long-term use. They can be used for a variety of applications, including relief stations and response headquarters during disasters, negative pressure rooms for infectious disease control, and open-air hospital facilities.

Maintenance is assured because the entire process, from design to manufacturing, is done in Japan. We can also respond to customer requests.

Related Achievements

Features

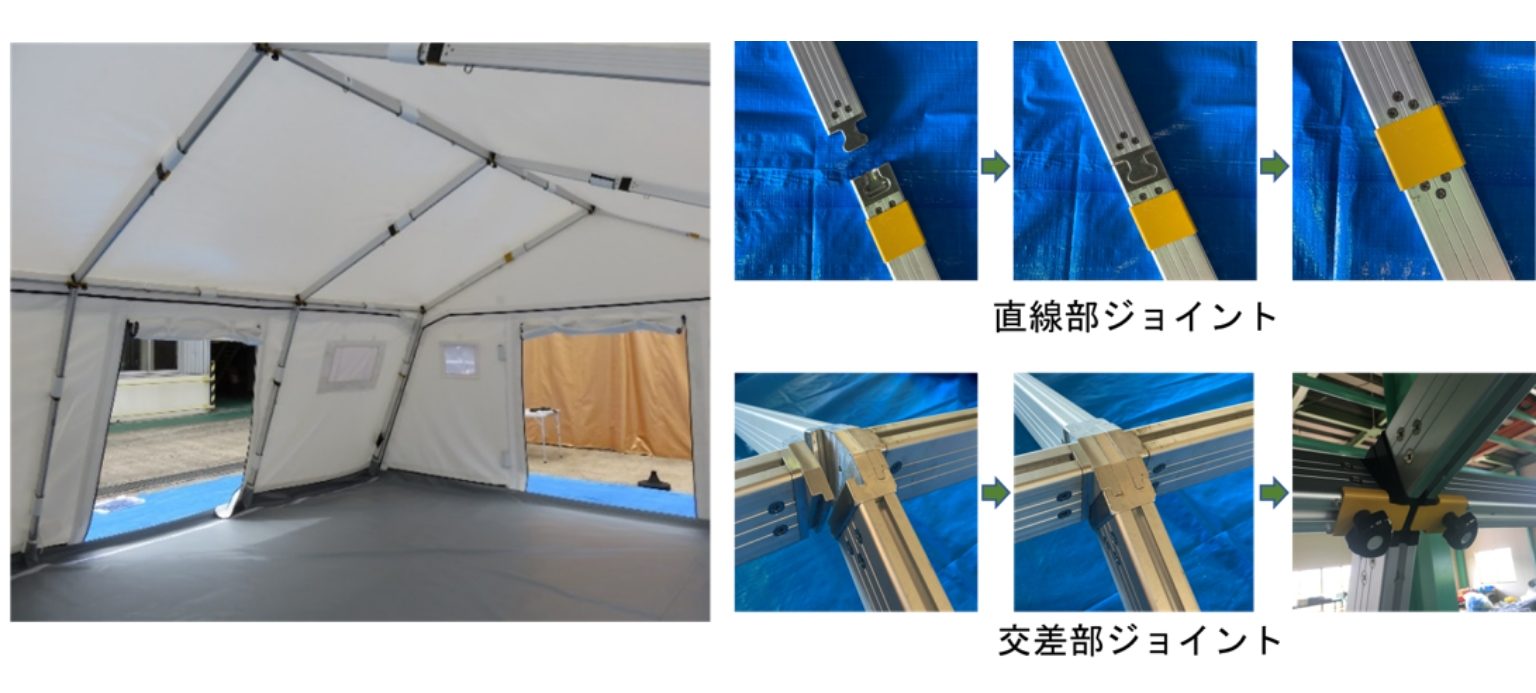

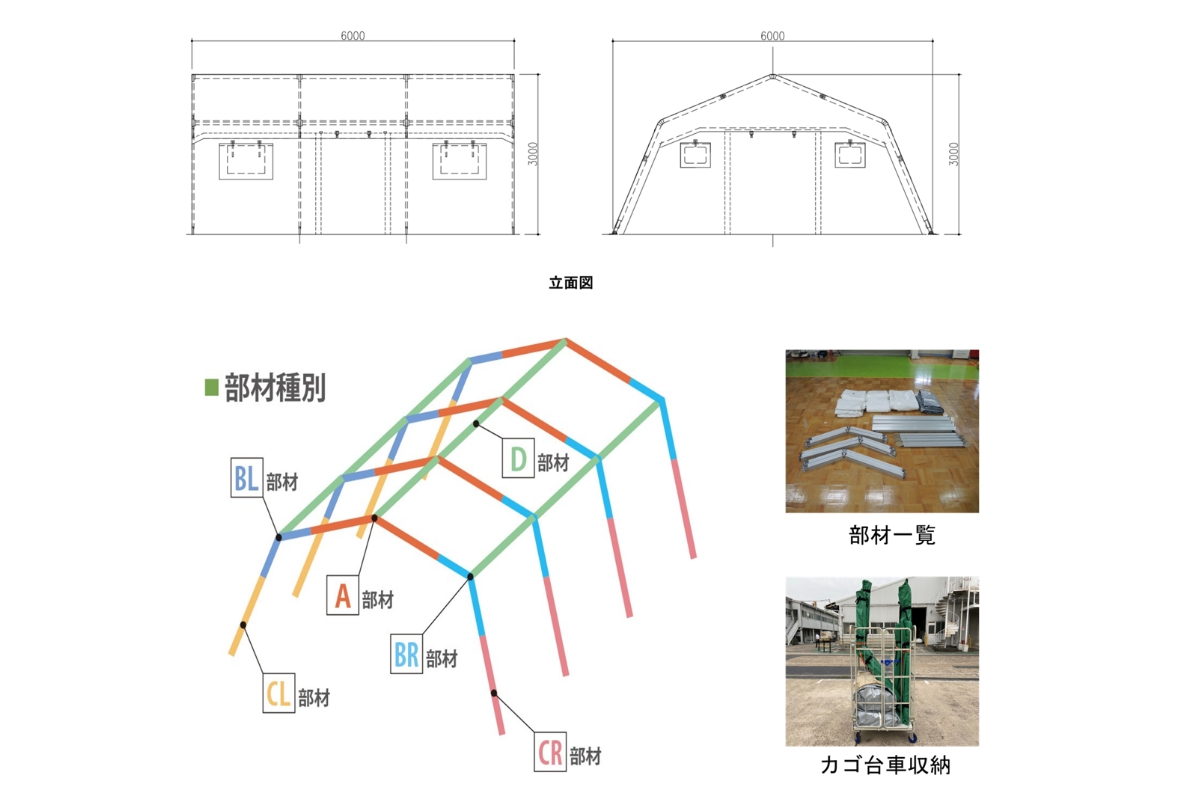

Simple frame structure and joint method

The frames are arranged to prevent problems such as damage caused by concentrated force on the members during setup and use. The joints of the frames are simple, so anyone can set up safely and easily.

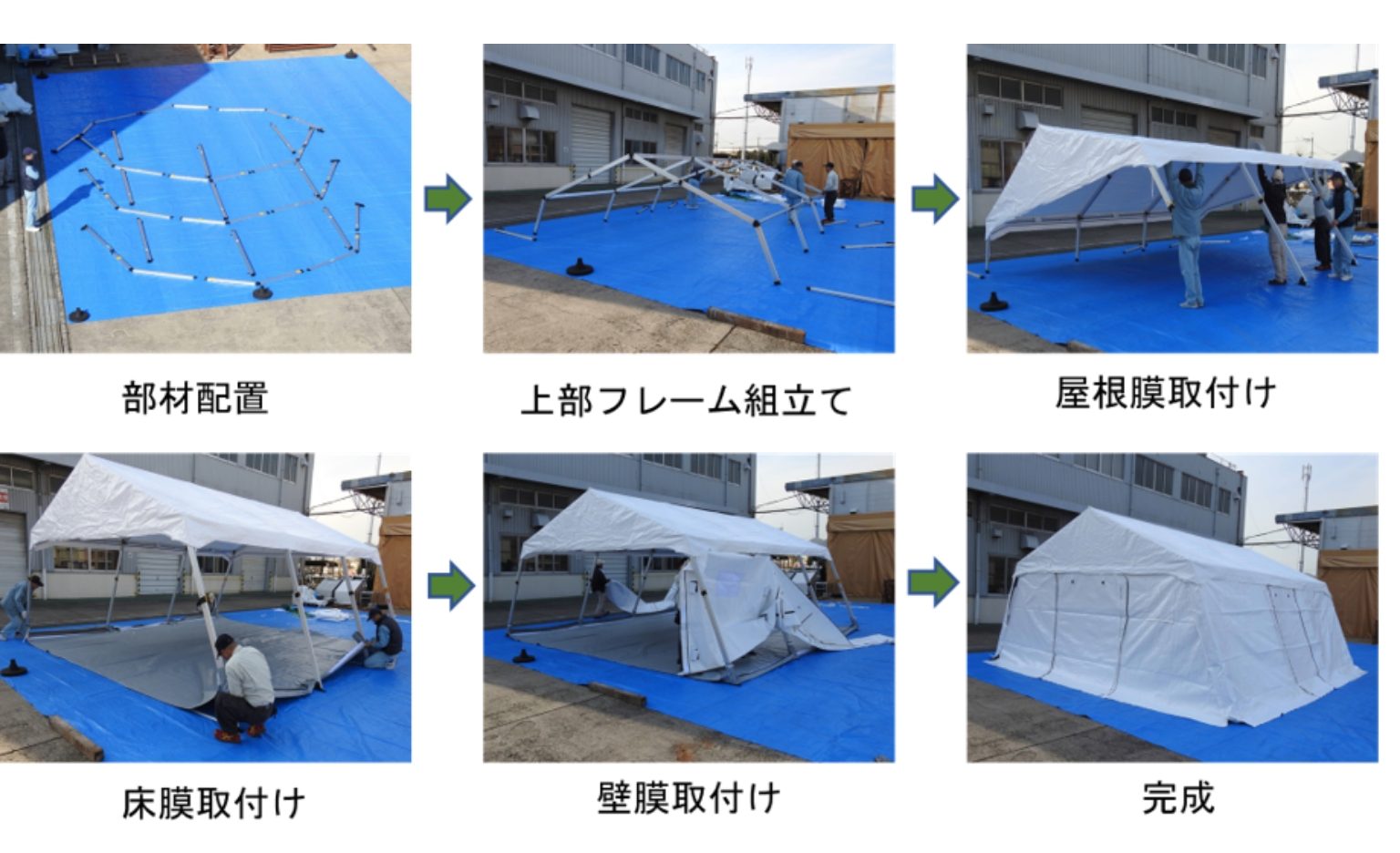

Setup procedures

The minimum number of people is 4, and setup can be done in about 20 minutes. No tools are required, and work can be done safely.

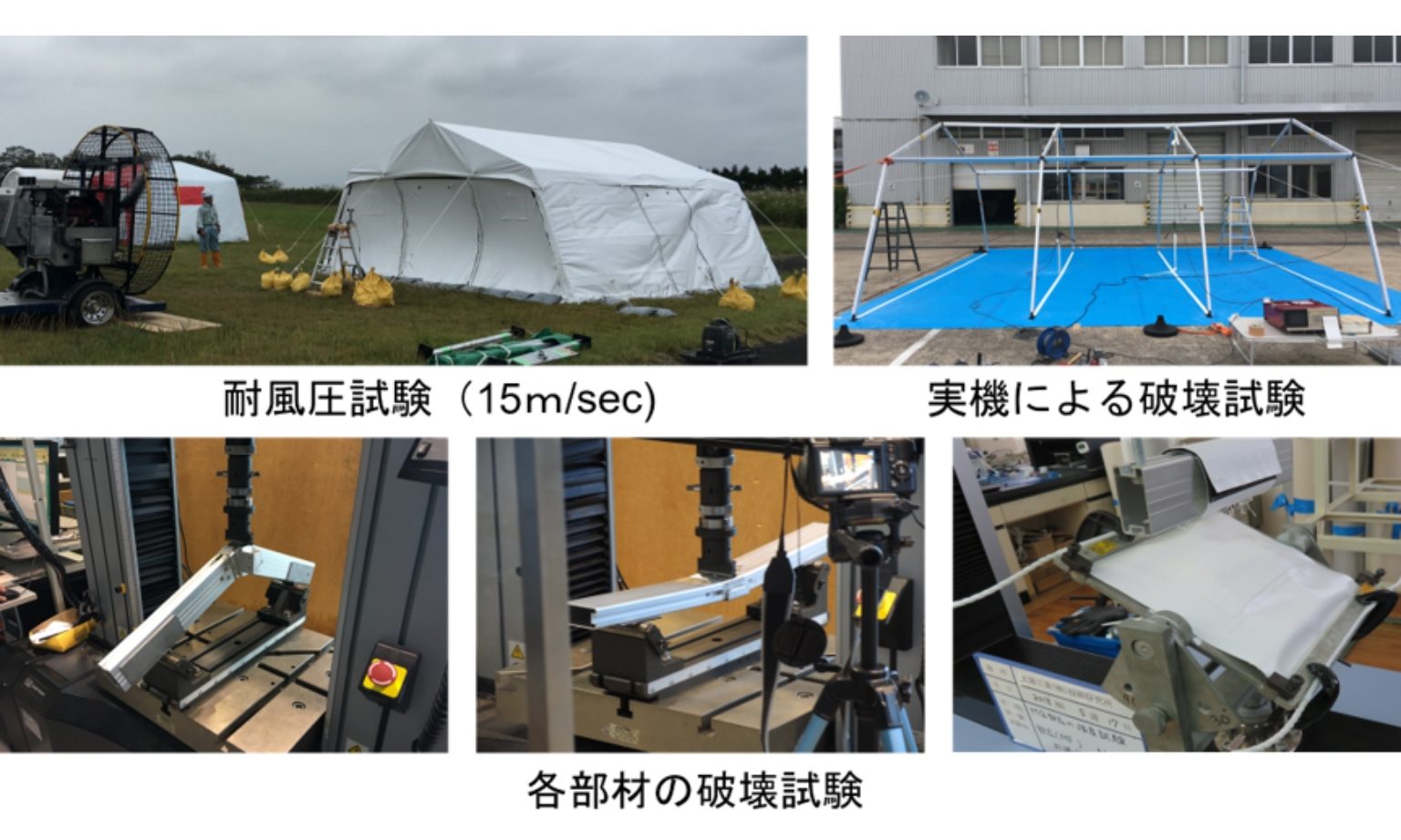

Confirmation of safety

Products that are expected to be used over the medium to long term require even higher levels of safety. Frame Tent is designed using applied analytical technology based on our many years of experience with membrane structures.

In addition, joint parts and other components are subjected to destructive testing, and the entire “frame tent” is subjected to wind pressure resistance testing using actual equipment to confirm safety. (Wind speed: 15 m/sec, snow accumulation: 10 cm)

Dimensions, material type

The following is a drawing of a “frame tent” and the types of components that make up the tent. Click on the image to view.

Standard specification

| parts | volume | packing quantity | dimensions of 1 package | weight | |

|---|---|---|---|---|---|

| frame | A Part | 4 | 1 | Width 0.6m x Length 2.0m x Height 0.2m | Approx. 20kg/package x 7 packages |

| BR Parts | 4 | 1 | Width 0.7m x Length 2.0m x Height 0.2m | ||

| BL Components | 4 | 1 | |||

| CR parts | 4 | 1 | Width 0.4m x Length 1.5m x Height 0.2m | ||

| CL Member | 4 | 1 | |||

| D Component | 9 | 2 | Width 0.5m x Length 2.2m x Height 0.2m | ||

| total amount | 29 pcs. | 7 packaging | Total 140kg | ||

| tent | roof membrane | one sheet | 1 | Width 1.0m x Length 1.0m x Height 0.6m | Approx. 40kg |

| gable membrane | two sheets | ||||

| wall membrane | two sheets | 1 | Width 1.0m x Length 1.0m x Height 0.7m | Approx. 50kg | |

| floor membrane | one sheet | ||||

| total amount | 6 sheets | 2 packages | Total approx. 90 kg | ||

| assembly time | Approx. 20 minutes (4 persons) | ||||

| accessory | Blue sheet, rope, hammer, pegs | ||||

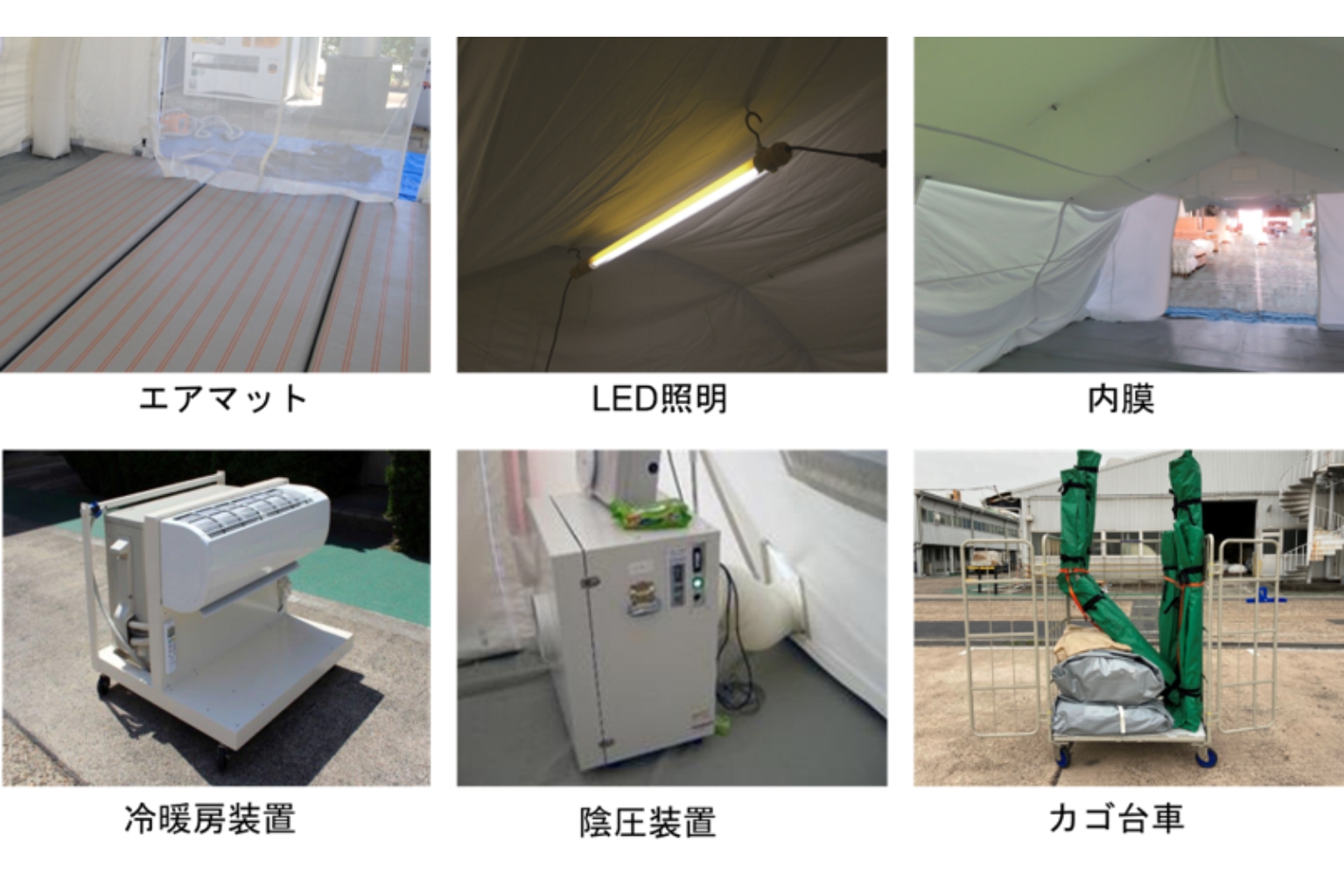

| option | Air mats, LED lighting, inner curtains, partition cloth, basket carts, air conditioning equipment, negative pressure equipment, positive pressure equipment, generators, floor pallets, connecting cloth | ||||

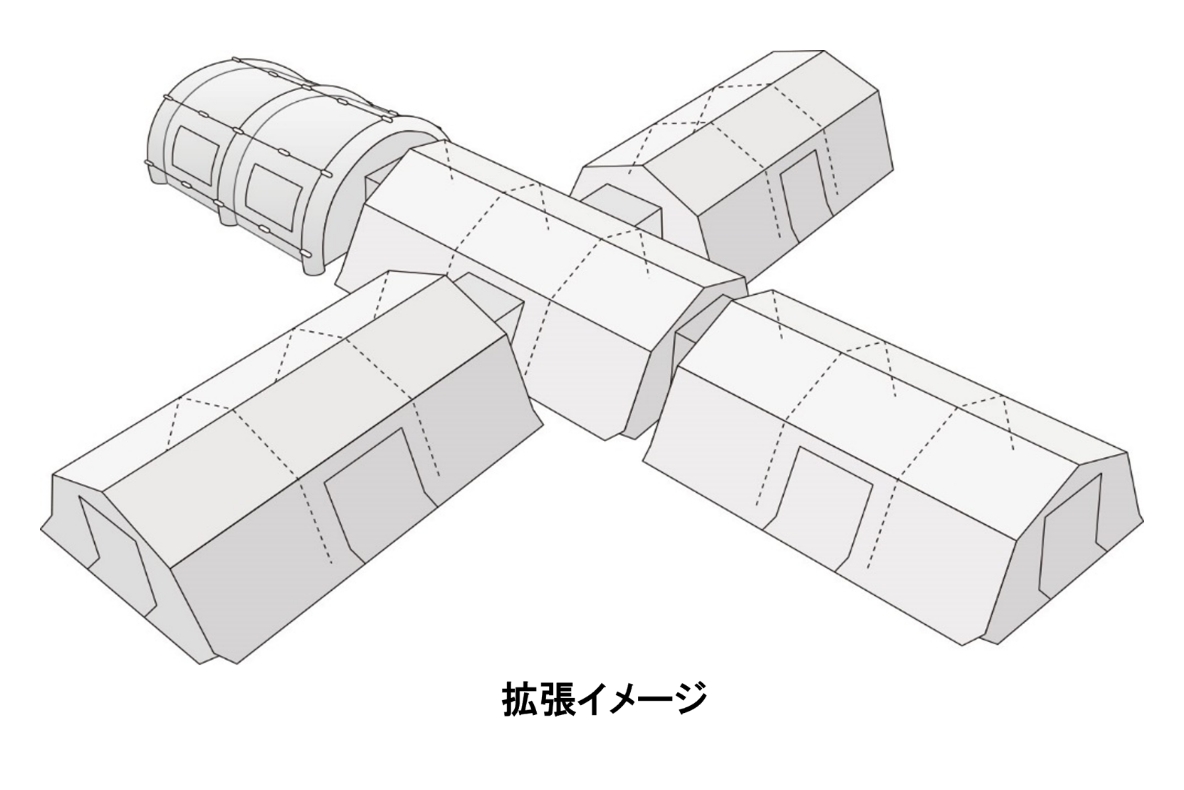

Scalability, applicability

Frame tents can be connected vertically or horizontally, allowing for a variety of designs and combinations. If the conditions are right, the frame and joint members can be modified in terms of frontage, length, and other dimensions while taking advantage of their unique characteristics.

Option

To make the Frame Tent even more useful, a variety of options are available.