”BIG MQ" Large Air Shelter

This large air shelter is resistant to strong winds and can be set up quickly.

BIG MQ is a large air-beam type shelter that can be quickly set up and taken down by human workers without the use of heavy machinery. It can be used for various purposes such as evacuation shelters during disasters, temporary medical facilities, event venues, and work site sheds.

Safety is taken into consideration, with everything from design to manufacturing being done in Japan. We also provide complete maintenance support, including on-site parts replacement.

Related Achievements

Product & Service

Features

Unique dual-tube air beam joint structure

The air beam is of the inner bag type (double tube type) which is airtight and easy to maintain.

The main beam diameter is 70 cmφ and the sub-beam diameter is 50 cmφ, each of which can be disassembled. This structure allows for compact storage and on-site maintenance. It is also possible to change the dimensions of the design as needed.

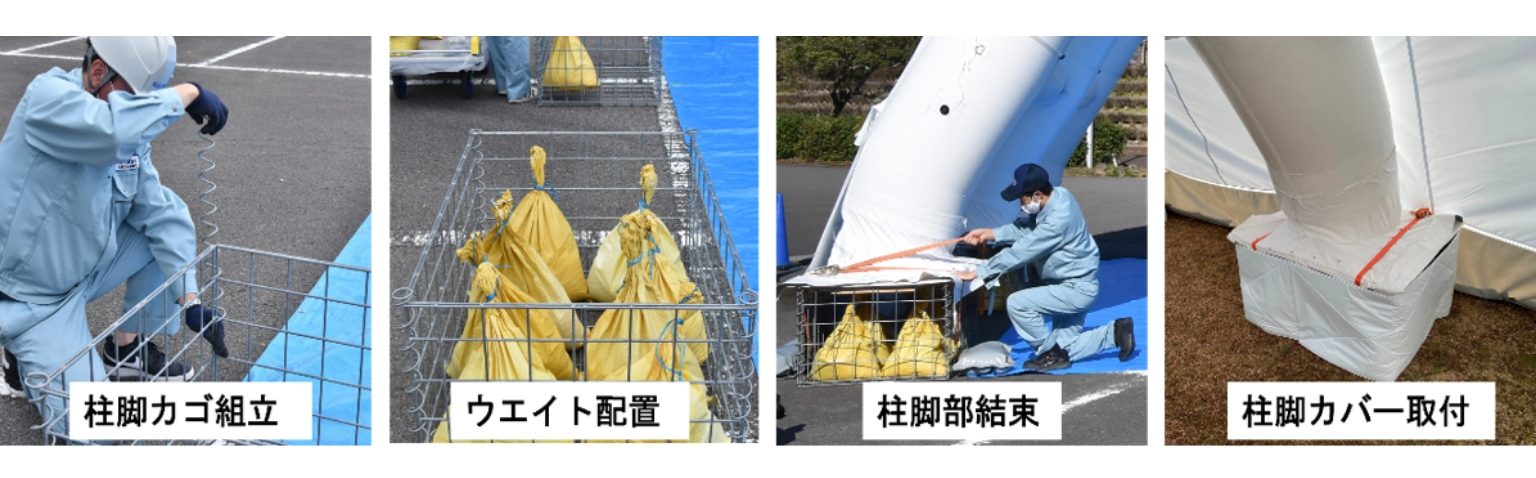

Setup Procedures

Each part is transported to the installation site by cart or other means. After positioning the column legs and unfolding the roof membrane, the beam and the column leg cage are tied together.

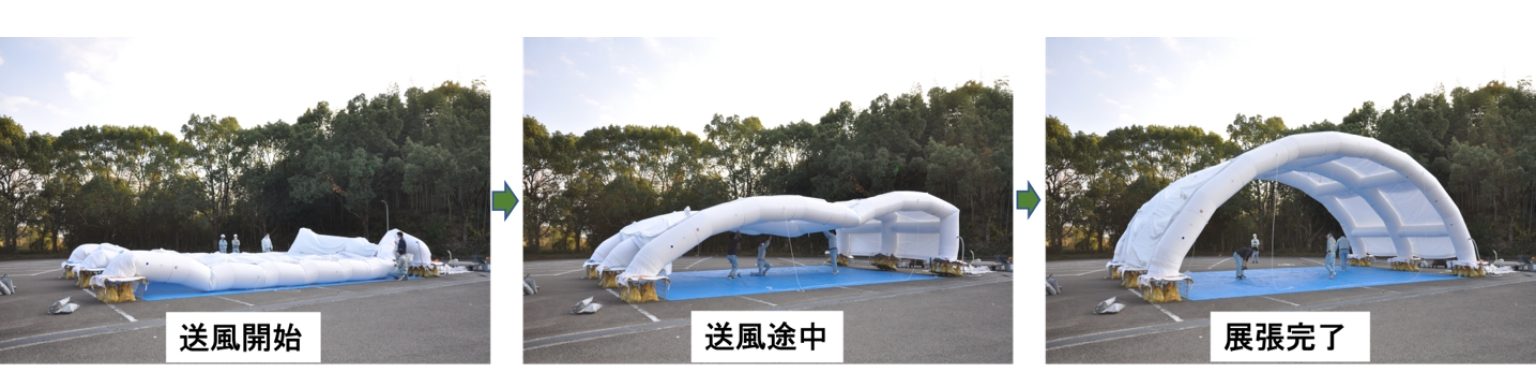

Air up (expansion)

The electric blower blows the air to stretch the sheets. (The stretching process is completed in about 10 minutes after the air blower starts.)

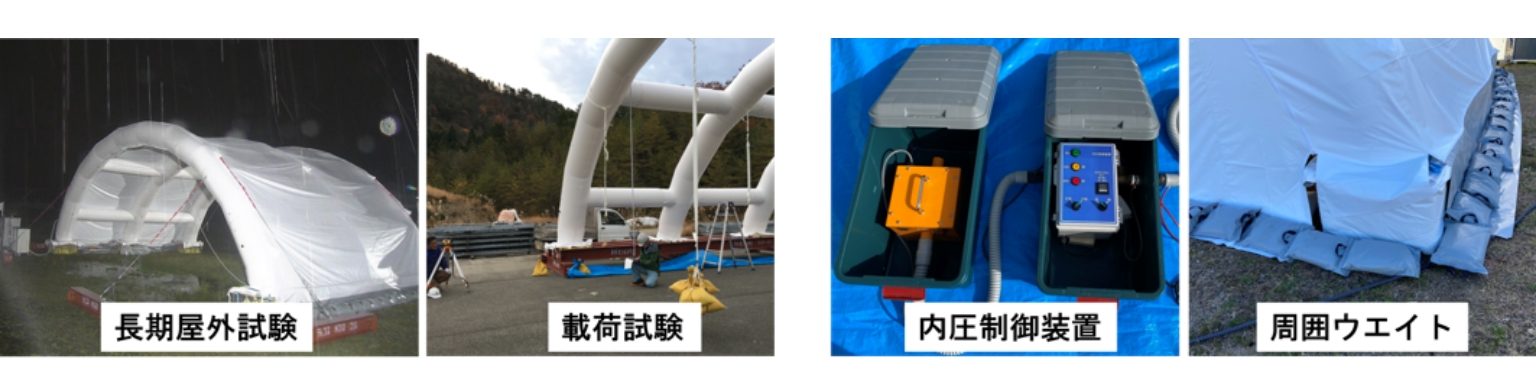

Reliable safety

Large products require greater safety, and the BIG MQ was designed using finite element analysis based on many years of experience with membrane structures, as well as a variety of demonstration tests.

Sufficient weights are placed on the column legs and tent perimeter, and an internal pressure controller is provided to maintain the required internal pressure for the air beam.

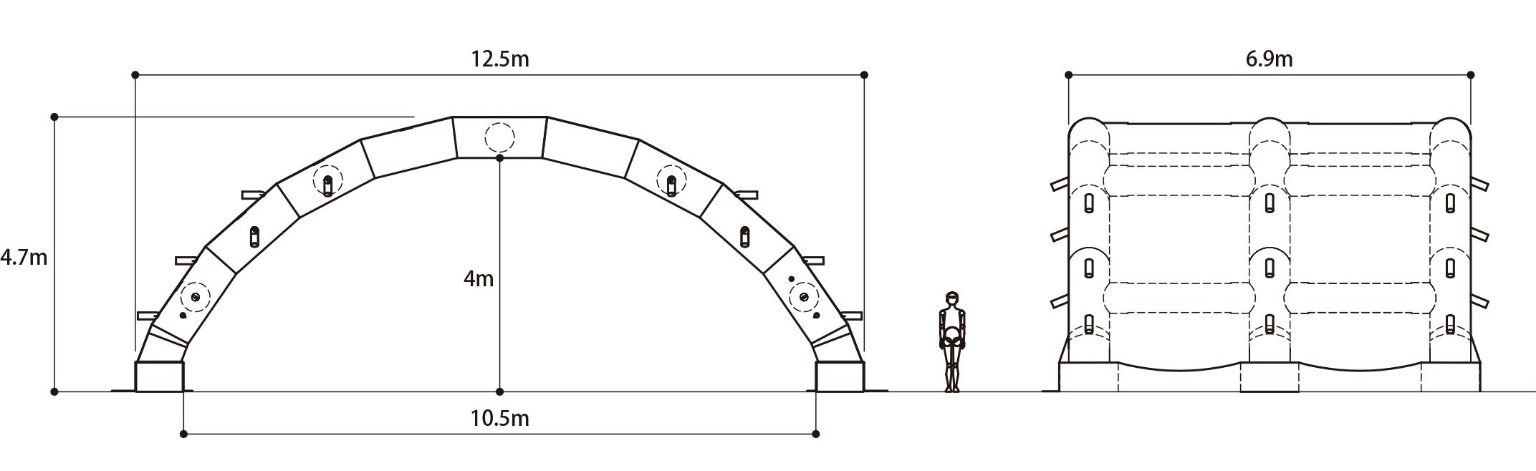

Standard dimensions

Standard dimensions

| technical specification | |

|---|---|

| Structure | Air-filled air tent (inner bag specification) |

| Beam Diameter | Main beam diameter φ70cm Sub-beam diameter φ50cm |

| Room size (in a store) | External dimensions: Width 12.5m x Depth 6.9m x Height 4.7m Internal dimensions: Width 10.5m x Depth 6.9m x Height 4.0m |

| Tent weight | Approx. 240 kg (roof membrane + air beam), not including column legs and weights |

| Membrane material | [AirBeam] Polyester fiber cloth + PVC resin coated membrane material [Inner bag] Polyurethane film (200µ) [Roof and floor membranes: Polyester fiber cloth + PVC resin coated membrane material |

| Ventilator | Two dedicated blowers are used for stretching After stretching, one unit is connected to the internal pressure controller |

| Air beam internal pressure | Standard internal pressure: 7 to 10 kPa |

| Design wind speed | Max. 15 m/s |

| Number of installation workers | 4 or more adults |

| Parts name | Size/Specifications/Quantity | Quantity | |

|---|---|---|---|

| air beam | Storage dimensions (cm): W100 x L120 x H80 | 1 unit | |

| membrane roof | Storage dimensions (cm): W100 x L120 x H80 | 1 unit | |

| Base Sheet | |||

| Air blowing unit | Blower: MQP-2500 with air hose | 2 sets | 1 unit |

| Internal pressure controller | With connection hose (with storage box) | 1 unit | |

| gauge sheet (gauges) | 7.2m x 11m, #2500 | one sheet | |

| Column leg fixing tape | lashing tape | 12 pcs. | |

| plank used to dry wet clothes or paper | φ8 x 10m | 15 pcs. | |

| peg | 12 mm dia. x 400 mm | 15 pcs. | |

| hammer | 1 lb. | one clique | |

| repair set | Repair sheet (adhesive sheet) | 1 formula | |

| Mesh basket for column legs | Assembly dimensions (cm): W100 x L80 x H50 | six sets | 1 unit |

| Base plate for column legs | Board dimensions (cm): 90 x 90 x t1.2 | six flat objects (e.g. tickets, pieces of cloth, pieces of cloth, etc.) | |

| Column leg weights | Sand bag 10kg/piece x 30 pieces | 1 unit | |

| weight | Sand bag 15kg/piece x 80 pieces | 4 units | |

| Wife membrane (optional) | Zipper detachable type | two sheets (pieces) (of paper) | 1 unit |