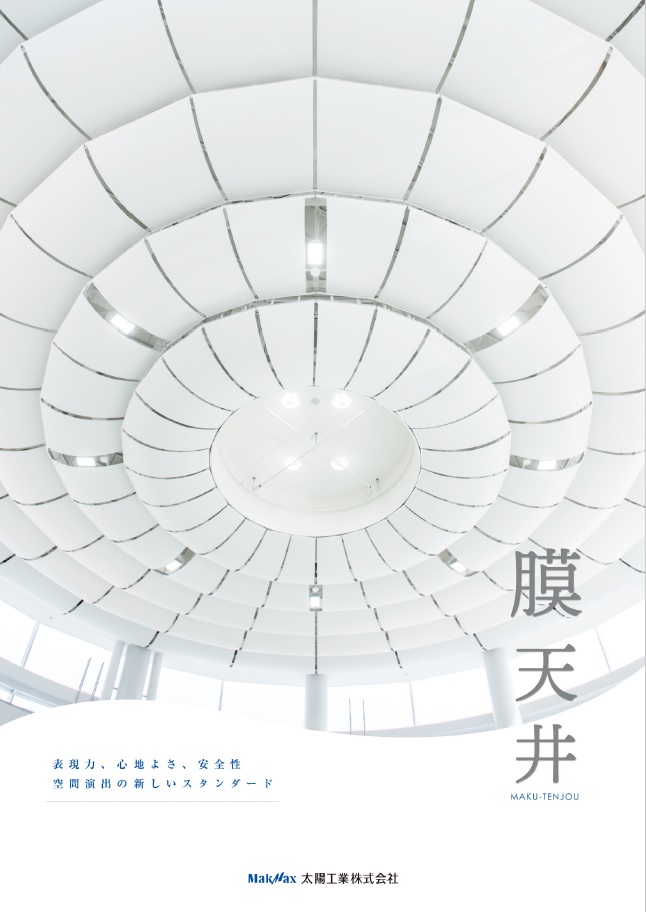

Membrane Ceiling

Safe and comfortable. Rich in design and environmentally friendly, this is the ceiling of the future.

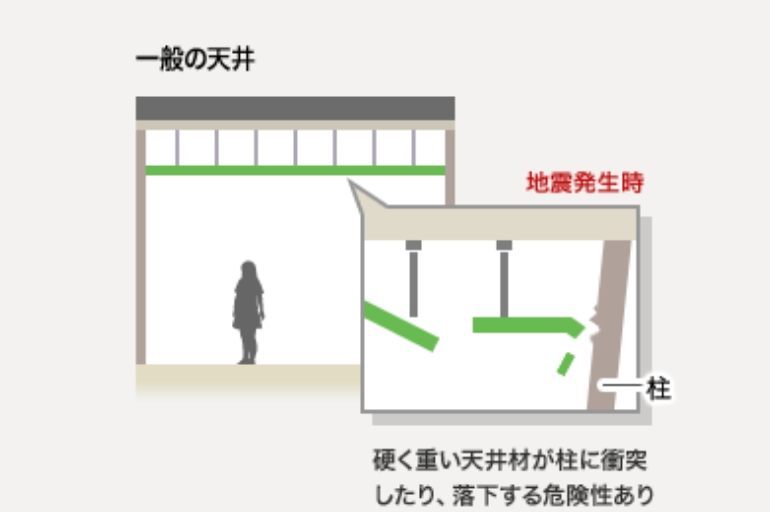

Ceilings are not only at risk of falling during major earthquakes. Ceilings falling due to aging and deteriorating base materials, daily delicate vibrations, wind and thermal contraction, and other such causes have been reported all over the world today.

Replacing heavy and hard conventional ceilings, a new concept of soft, lightweight, and strong membrane ceilings gently wrap people’s lives.

Related Keywords

- Public Architecture

- Architectural Business

- Private Architecture

- Global Business

- Facilities

- Transportation Facilities

- Educational / Cultural / Government Facilities

- Commercial Establishments

- Medical care / Welfare facilities

- Productive Facilities

- Government / Public Corporations

- Health and Social Care

- Schools / Education

catalog

Related Achievements

Product & Service

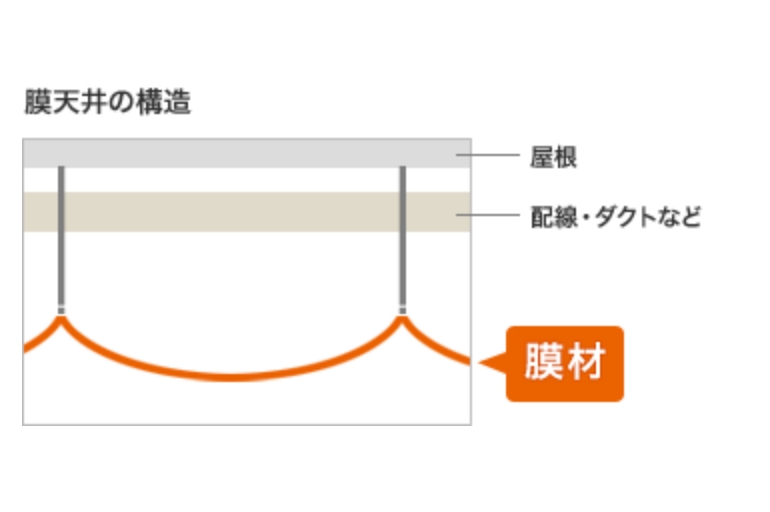

What is a Membrane Ceiling?

This ceiling construction method creates safe and comfortable spaces.

The danger of falling ceilings is not limited to major earthquakes. Aging and deterioration of the base material, daily delicate vibrations, cold and heat shrinkage. Ceiling falls due to these causes have been reported all over the world today.

Replacing heavy and hard conventional ceilings, a new concept of soft, lightweight, and strong membrane ceilings gently wrap people’s lives.

Feature

Light

Less damage in case of a fall

The mass of the membrane material is approximately 600 g/m². Compared to conventional ceiling materials, it is very lightweight, minimizing damage to people and objects in the room in the event of an unexpected fall.

Soft

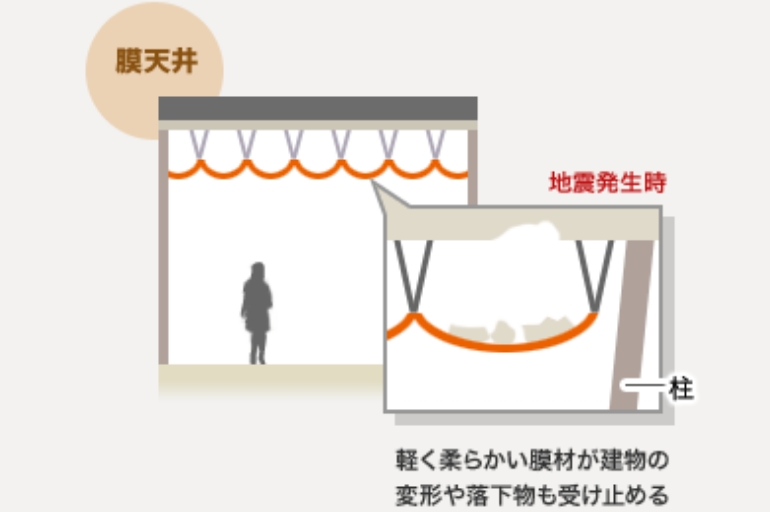

Resistant to deformation and collision, and resistant to swaying and falling

The thin and soft membrane material not only enhances the room’s design, but also makes the structure capable of following deformation even in the event of large seismic shaking, thus reducing the risk of ceiling fallout to an extremely low level.

Strong

Catching Falling Objects

In spite of its extremely thin material with a thickness of only 1 mm, it has been proven in in-house tests to be strong enough to catch falling objects.

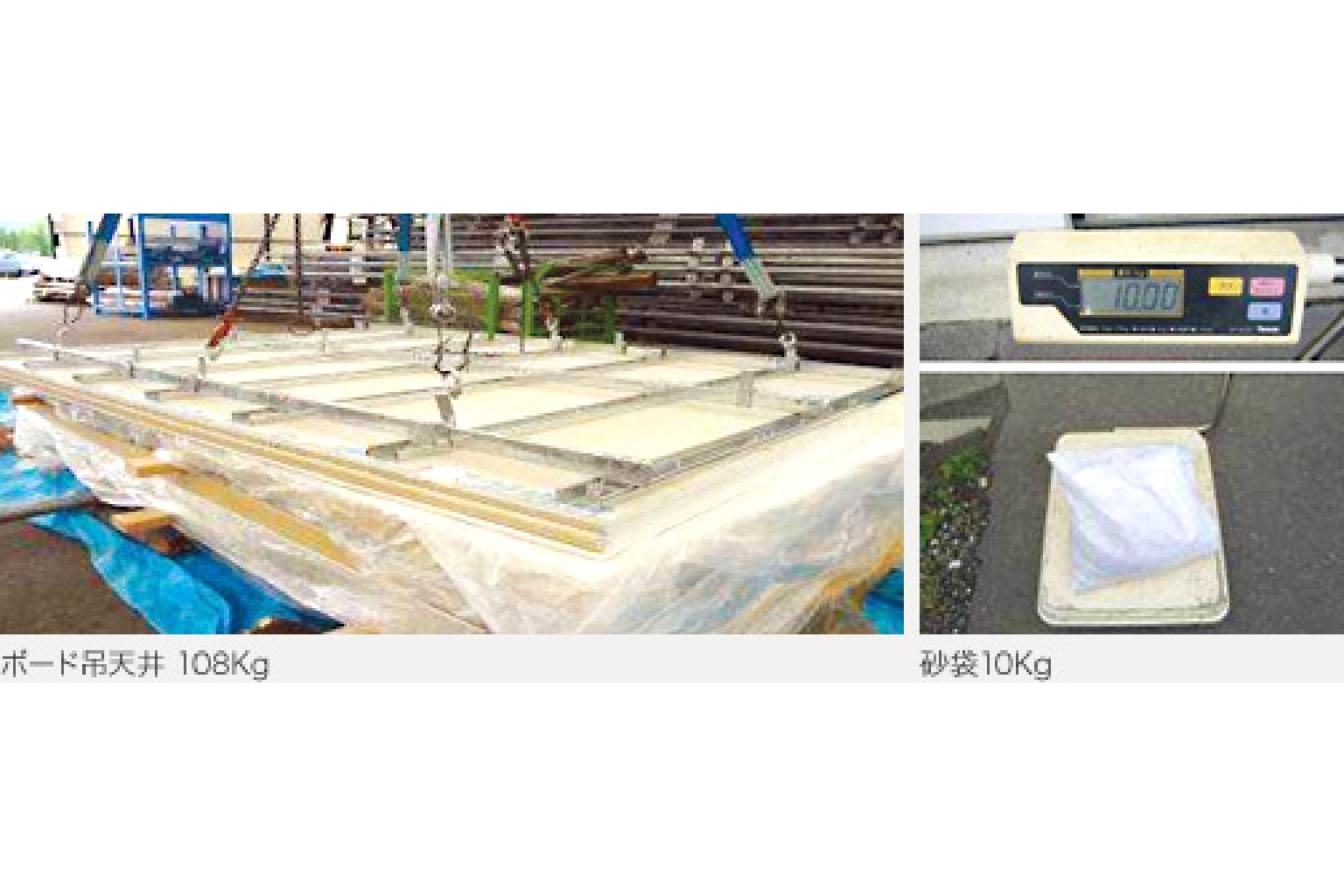

Drop Impact Testing of Membrane Ceilings - Membrane for Ceilings (BATYLINE)

Bright

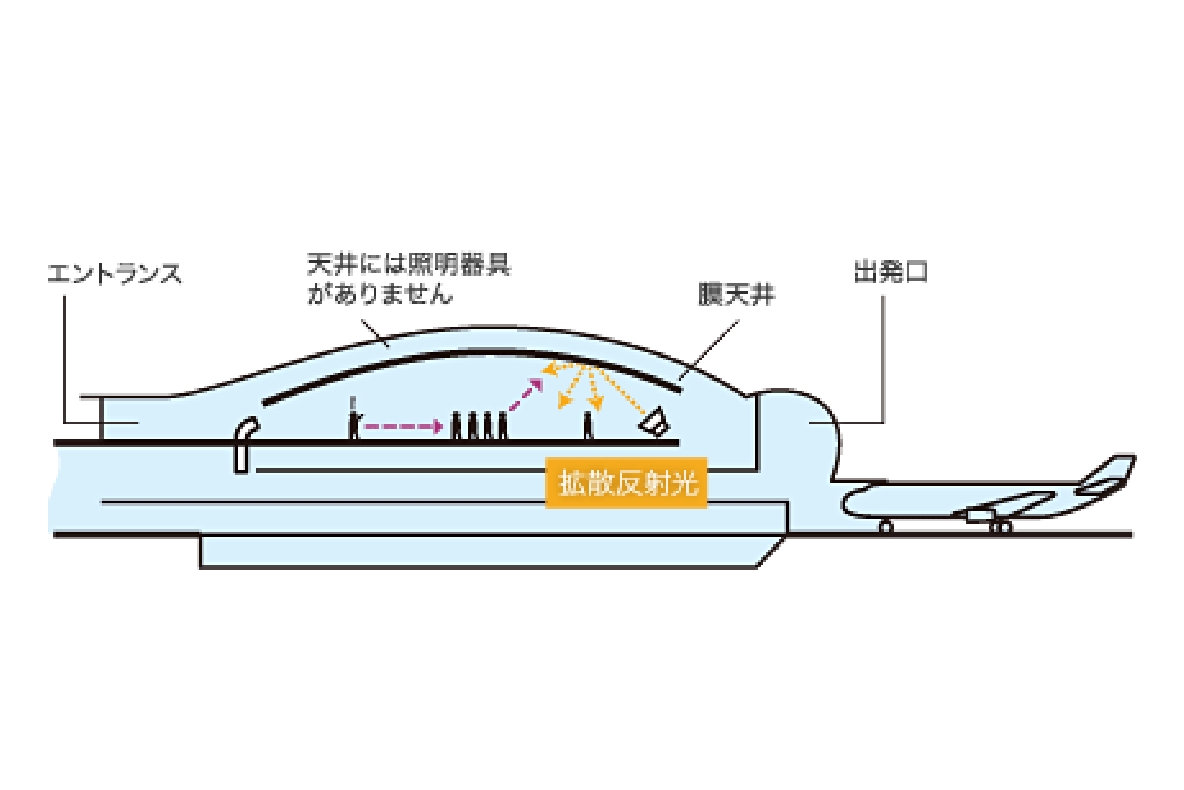

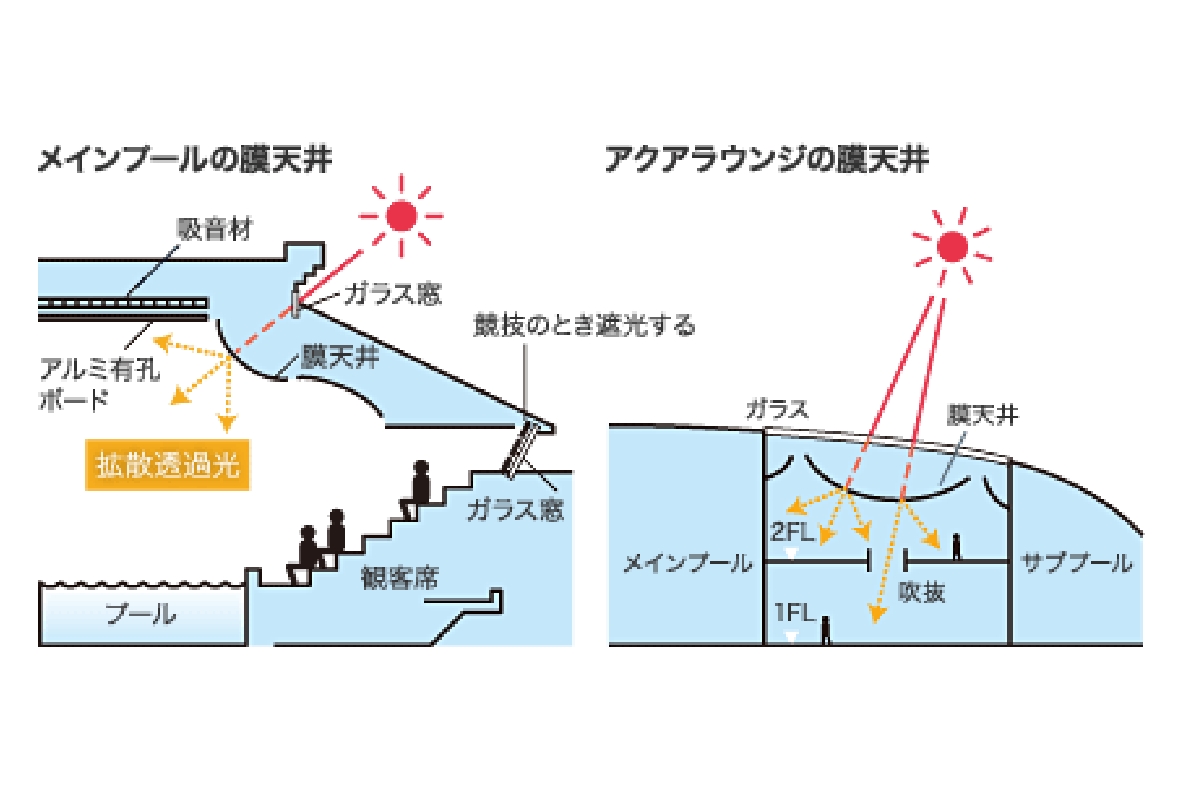

Space with high quality light environment

It creates a space with a high-quality light environment by reflecting natural lighting from windows or indirect lighting effects from light transmitted through the membrane material.

Example of indirect lighting effect

Kansai International Airport Passenger Terminal Building

Kansai International Airport Passenger Terminal Building

Chiba International Swimming Center

Chiba International Swimming Center

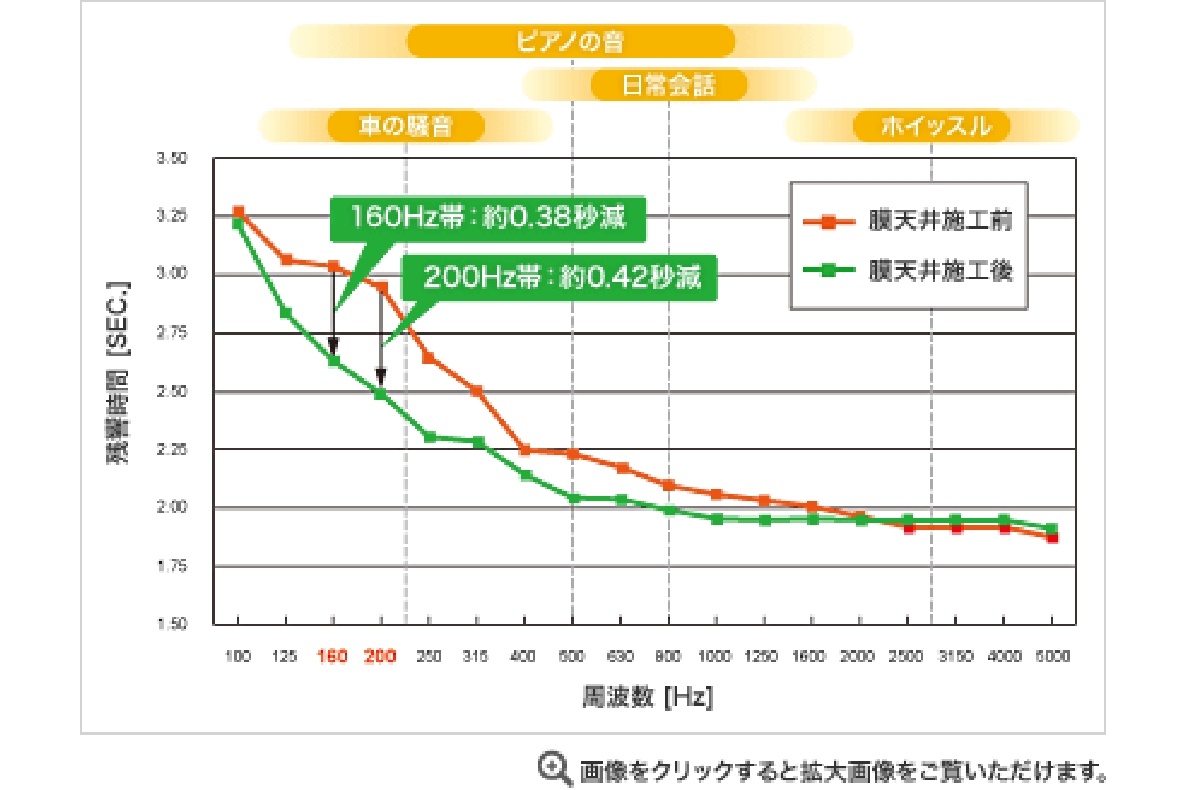

Sound absorption performance

Control room reverberation

Acoustic Measurement Tests

Membrane material: BATYLINE Aw

Facility name: Kurashiki City Indoor Swimming Center (indoor pool)

Room volume: approx. 9,000m² (25m x 36m x 10m)

| Date of measurement | Temperature | level of humidity | |

|---|---|---|---|

| Before installation of membrane ceiling wood, hair and magnesium plate (t=25) |

2012/3/27 | 31°C | 50%. |

| After installation of membrane ceiling BATYLINE Aw (t=0.7) |

2012/7/10 | 32°C | 74%. |

Kurashiki City Indoor Swimming Center

Before installation of membrane ceiling

Before installation of membrane ceiling

After installation of membrane ceiling

After installation of membrane ceiling

Comparison of reverberation time before and after installation of membrane ceiling (average value per frequency)

After the membrane ceiling was installed, we confirmed that the reverberation time was reduced, mainly in the 160-200 Hz band.

Air conditioning efficiency

Control airflow to increase air conditioning effectiveness

We cooperated with the Kawaguchi Laboratory of the University of Tokyo’s Institute of Industrial Science in thermal environment measurement experiments, and confirmed that installing a membrane ceiling can control airflow in a room and save energy.

Experimental measurement of humidity-thermal environment of retractable membrane ceilings

When the membrane ceiling is closed

When the membrane ceiling is closed

When the membrane ceiling is fully opened

When the membrane ceiling is fully opened

Objective

- Verify the effectiveness of the membrane ceiling in blocking airflow by comparing the vertical temperature distribution in both the upper and lower spaces of the membrane ceiling when the membrane ceiling is closed and when it is fully open during the heating operation period in the winter.

- To verify the energy saving effect of the membrane ceiling by considering the change in heating load due to the opening and closing of the membrane ceiling.

Membrane Ceiling Overview

| establishment | 2012/11/28 |

|---|---|

| membrane material | Polyester membrane material |

| closing time (library, museum, etc.) | About 1 minute at the switch |

| area | 16m2 |

Measurement Summary

| Location | Measured items | number of measurement points | Measuring instruments | measurement method |

|---|---|---|---|---|

| indoor | Indoor air temperature, Walls, floors, Surface temperature of glass, etc, Air conditioning inlet/outlet temperature and humidity, air velocity |

Total 42 items | thermocouple | Continuous measurement 10 min/times |

| outside a room | Outside air temperature and humidity | one point | temperature controller |

Actual measurement result by thermo camera

By contrast of closing and fully opening the membrane ceiling, the membrane ceiling showed a blocking effect of about 4°C to 6°C when the heating was set at 22°C. (Kawaguchi Laboratory, Institute of Industrial Science, The University of Tokyo)

*From “Status of Demonstration Experiment at COMMA House (Institute of Industrial Science, University of Tokyo) www.commahouse.iis.u-tokyo.ac.jp.

Free design

It is also excellent in design, as it can accommodate curved surfaces and other free-form shapes.

Hakodate Racecourse

Main construction methods

Full circumference fixing type

Framing and anchoring membrane materials with ropes or aluminum anchoring systems

Features of Construction Method

- The membrane is fixed at all perimeters, allowing for fine adjustment and flat stretching.

- The shape is highly flexible and can be easily adapted to various room shapes, and can be easily combined with equipment and other facilities.

- Compared to other systems, the fusing frame is the heaviest.

2-sided fixing type

Method of fixing only the two ends of the membrane and suspending it freely without hearing.

Features of Construction Method

- Fewer components are used, and the installation is simple.

- The membrane’s ability to follow deformation is extremely high, and the risk of breakage or falling is low.

- Since no tension is applied, the reaction force is small and the load on the frame can be reduced, but the membrane is prone to wrinkling.

- The softness, lightness, and curved surface unique to membranes can be expressed.

Point suspension type

Method of providing hearing by attaching hardware at points around the perimeter of the membrane.

Features of Construction Method

- The outer perimeter is anchored at a point for quick installation and simple delivery with no need for intermediate framing.

- The membrane has higher deformation-following capability and is less likely to break or fall.

- The corresponding tension is applied to the membrane, resulting in a reaction force on the frame.

- It can express the light design unique to suspension membranes.

Construction Procedure

1. Install scaffolding on the ceiling and attach the base frame.

2. Measure the dimensions and install the bracket.

3. Set the support members on the membrane ceiling.

4. Attach the support member to the bracket.

5. The membrane ceiling is completed.

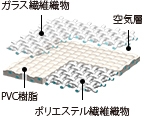

Membrane material type

| Membrane Material | Material Composition/Features | thickness [mm] weight [g/m²] Fabric width[mm] |

Visible light reflectance/ Transmittance [%] Transmittance |

Sound absorption coefficient [NRC値] note 1 |

Color variation | fire resistance performance | ||

|---|---|---|---|---|---|---|---|---|

| Sound absorbing membrane material | Flameproof Products | BATYLINE Aw |

Membrane material that is flexible, has high sound absorption performance, and is easy to install. |

0.7 JIS K 6404 600 JIS K 6404 2,700 |

White 91/7 Gray 64/2 Beige 53/2 Black 4/1 |

0.68 | Standard: White/Gray

Special order: beige/black

|

Flameproof products*3 Certification No. F-26117 (Japan Fire Retardant Association |

| non-inflammable material | VERVYFINE Aw |

A noncombustible material that is supple and highly sound absorbent. |

0.47 JIS K 6404 490 JIS K 6404 3,000 |

78/18 | 0.69 | white

|

Noncombustible materials*2 Certification No. NM-4223-1 Building Standard Law Article 2, Item 9 |

|

| GOTY Aw |

Washi-like noncombustible material specialized for 2-sided fixation type with high sound absorption |

0.60 JIS R 3420 460 JIS R 3420 2,000 |

64/28 | 0.70 | white

|

Noncombustible materials*2 Certification No. NM-4355 Building Standard Law Article 2, Item 9 |

||

| UNITYFINE Aw |

Membrane material with higher sound absorption performance through multi-layering. |

0.32 JIS K 6404 290 JIS K 6404 2,670 (excluding glass fiber fabrics) |

(Synthesis) White 65/7 Light gray 49/2 Anthracite 8/1 Quartz 65/6 Sandy Beige 48/3 |

0.74 | White / Light gray / Anthracite / Quartz / Sandy beige

|

Noncombustible materials*2 Certification No. NM-4071 Building Standard Law Article 2, Item 9 |

||

| Airtight membrane material | non-inflammable material | RESTYFINE |

Air-tight membrane material with excellent water resistance and versatility. |

0.37 JIS K 6404 502 JIS K 6404 2,000 |

91/4 | 0.10 | white

|

Noncombustible materials*2 Certification No. NM-4200 Building Standard Law Article 2, Item 9 |

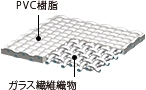

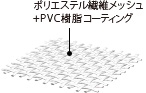

| Mesh membrane material | non-inflammable material | FT381 |

Mesh membrane material with high elasticity and an aperture rate of just under 28%. |

0.95 JIS K 6404 550 JIS K 6404 2,670 |

28%. (Aperture ratio) |

0.12 | Ash blonde / gray / beige / beaten metal / metallic

|

Flameproof products*3 Certification No. F-25272 (Japan Fire Retardant Association |

The above is a typical example. Other specifications are also available.

Product specifications are subject to change without notice.

The above values are based on measurements and are not guaranteed.

Color variations are for illustrative purposes only and may differ from actual products.

All membrane materials have been verified by a third-party organization to be equivalent to F☆☆☆☆. (Formaldehyde emission rate: less than 0.005mg/m²/h)

Caution should be exercised when using in swimming pools.

1 NRC value (Noise Reduction Coefficient) is the arithmetic mean of the sound absorption coefficient at each frequency of 250, 500, 1000 and 2000 Hz.

2 Noncombustible materials are building materials certified by the Minister of Land, Infrastructure, Transport and Tourism as having noncombustible performance as defined by the Building Standard Law.

3 Flameproof products are products certified by the Japan Fire Retardant Association based on flameproof performance standards, etc. established by the Flameproof Product Certification Committee.

Verification Video

BATYLINE Aw

Glass cloth noncombustible membrane material

FT-381

Verification of ball impact on membrane ceiling

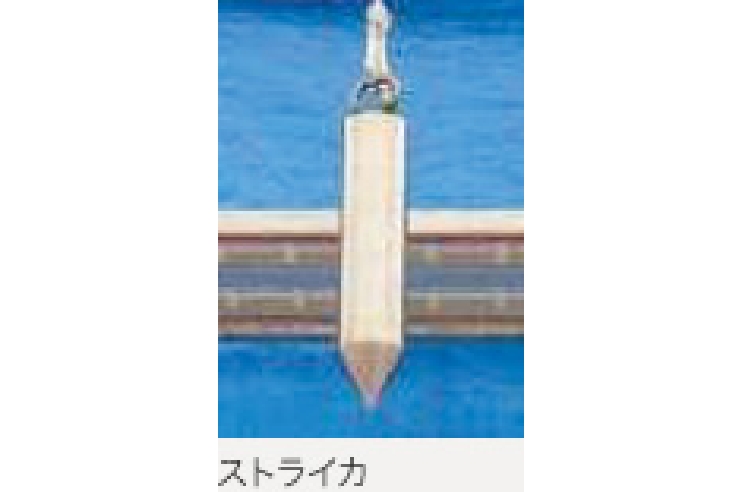

Test Contents

Penetration resistance test

A 3 kg striker (stake) was dropped from a height of 1 m onto the center portion and the edge of the membrane surface.

*This test conforms to the “Standard for Protective Caps” as stipulated in Article 42 of the Industrial Safety and Health Law by the Ministry of Health, Labor and Welfare.

Drop impact test

- A 10 kg sand bag was dropped from a height of 1 m onto the center portion and the edge of the membrane surface.

- A suspended ceiling with boards assumed to be the finishing material is dropped horizontally onto the membrane surface.

- The suspended ceiling, with the board assumed to be the finishing material, is dropped at an angle to the membrane surface.

*The weight of the suspended ceiling is 108 kg (44 kg/m²).