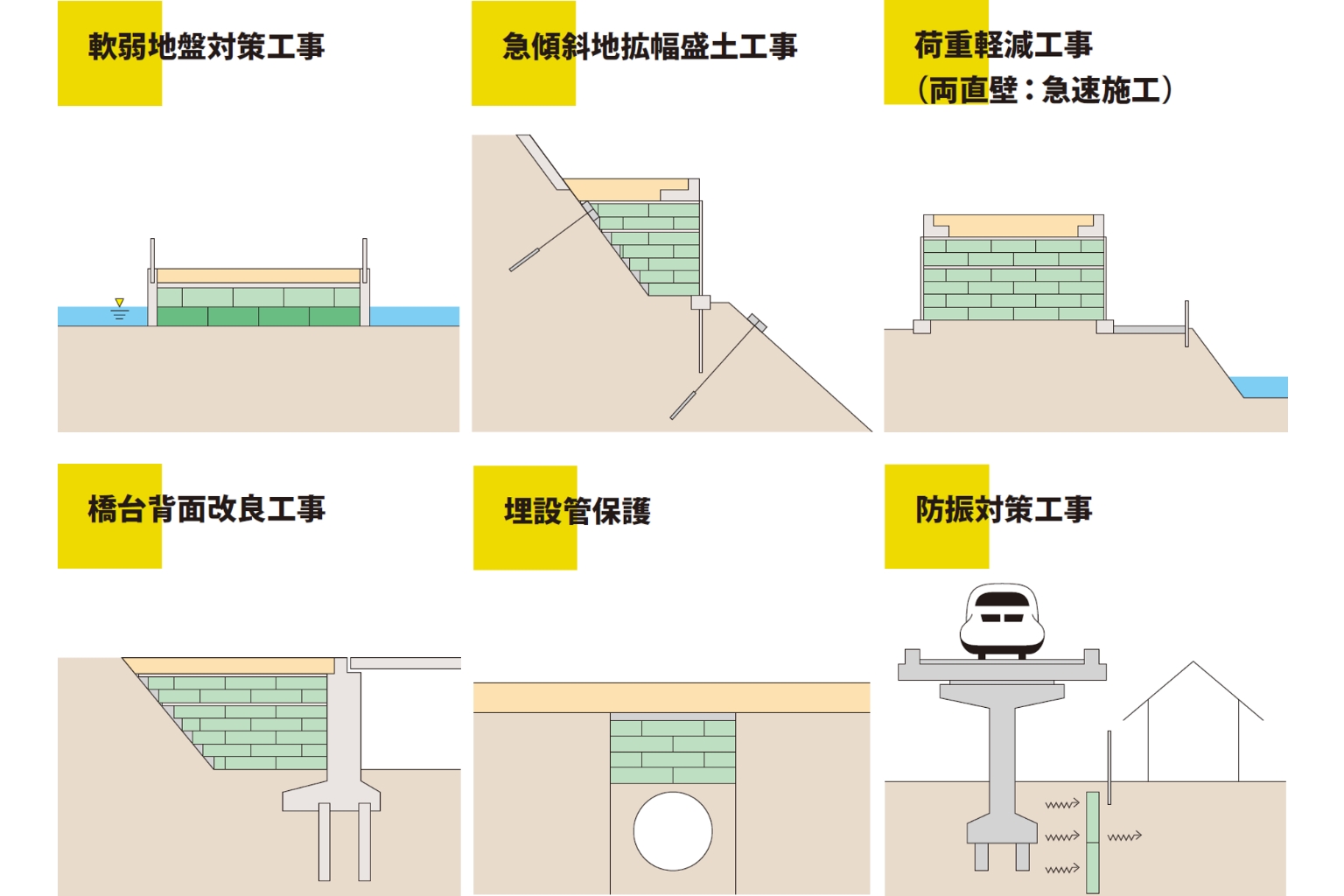

"EDO-EPS Method"

-Lightweight embankment method-

The EDO-EPS method is a lightweight embankment method that uses large Styrofoam blocks (product name: Tough Block) as the fill material.

This construction method utilizes the excellent features of Tough Block, such as its ultra-light weight, compression resistance, self-support, and earthquake resistance.

*For sale only in the Japanese market

Related Achievements

Product & Service

forte

Lightweight

Styrofoam is 1/100th the density of soil, sand, or concrete, and is 1/10 to 1/50th the weight of other lightweight materials, making it easy to transport by hand. It can also solve problems such as settlement and lack of support in soft ground.

Compressibility

The compressive strength of EDO-EPS blocks was tested in accordance with JIS K 7220 and confirmed to have an allowable compressive stress of 35-350 kN/m2 or higher, which is sufficient to meet the required strength as an embankment material.

Independence

Since Styrofoam blocks are self-supporting, the stacked structure can be used as a freestanding wall.

Earthquake-proof

Since it is lighter than earth and sand, it is highly safe even in large earthquakes.

Econmic

In addition to shortening the construction period, ground treatment and temporary construction can be simplified, and the land required for construction can be minimized, contributing greatly to the reduction of construction costs.

Workability

No need for large construction equipment, and easy to install by human labor. It enables rapid construction even on soft ground or steep slopes where it is difficult to use large construction equipment. In addition, blocks can be easily cut on site, allowing for easy processing according to the terrain.

Main components and installation procedures

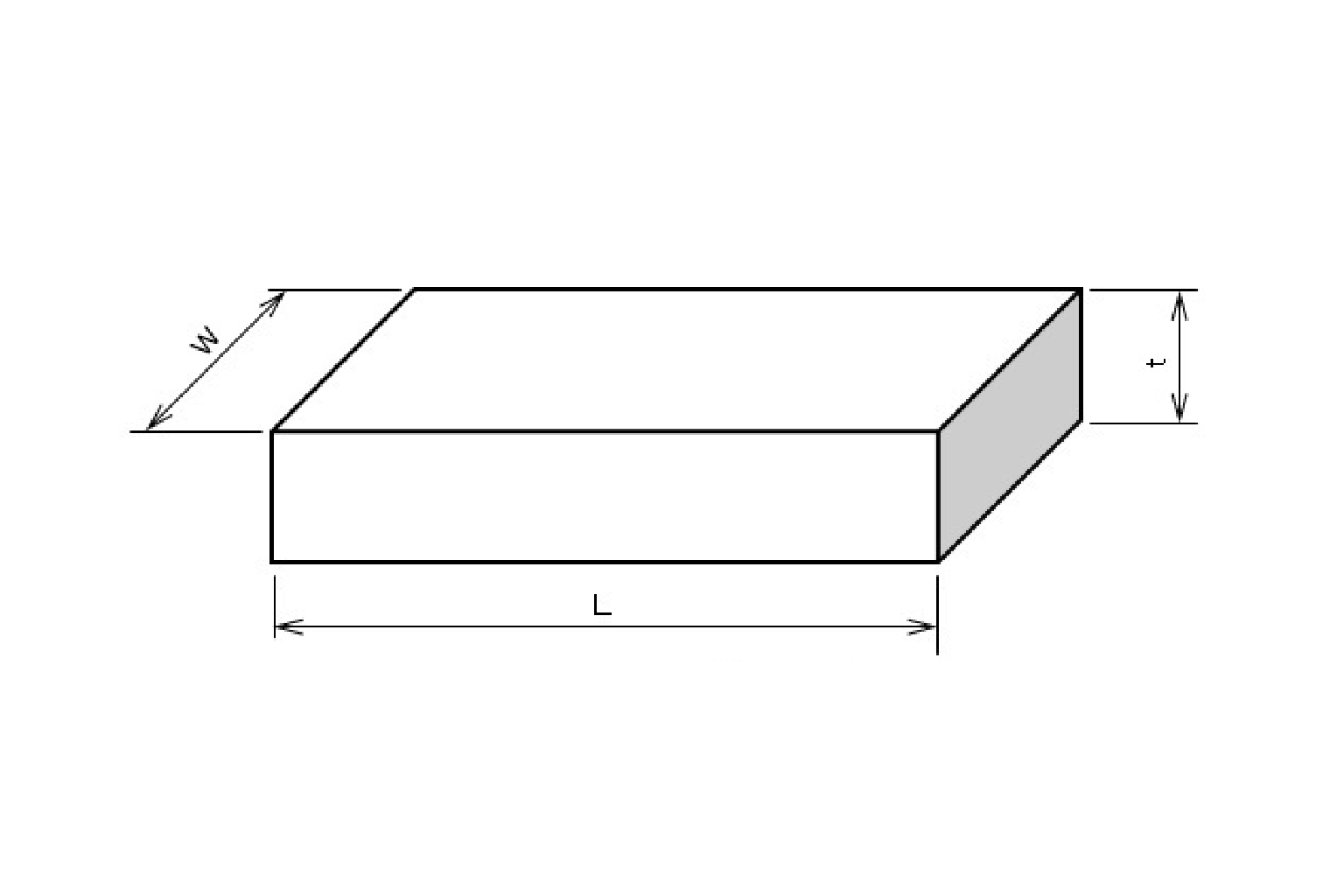

EDO-EPS block

Shape and Dimensions

1.0m(W)×2.0m(L)×0.5m(t)

Hydration

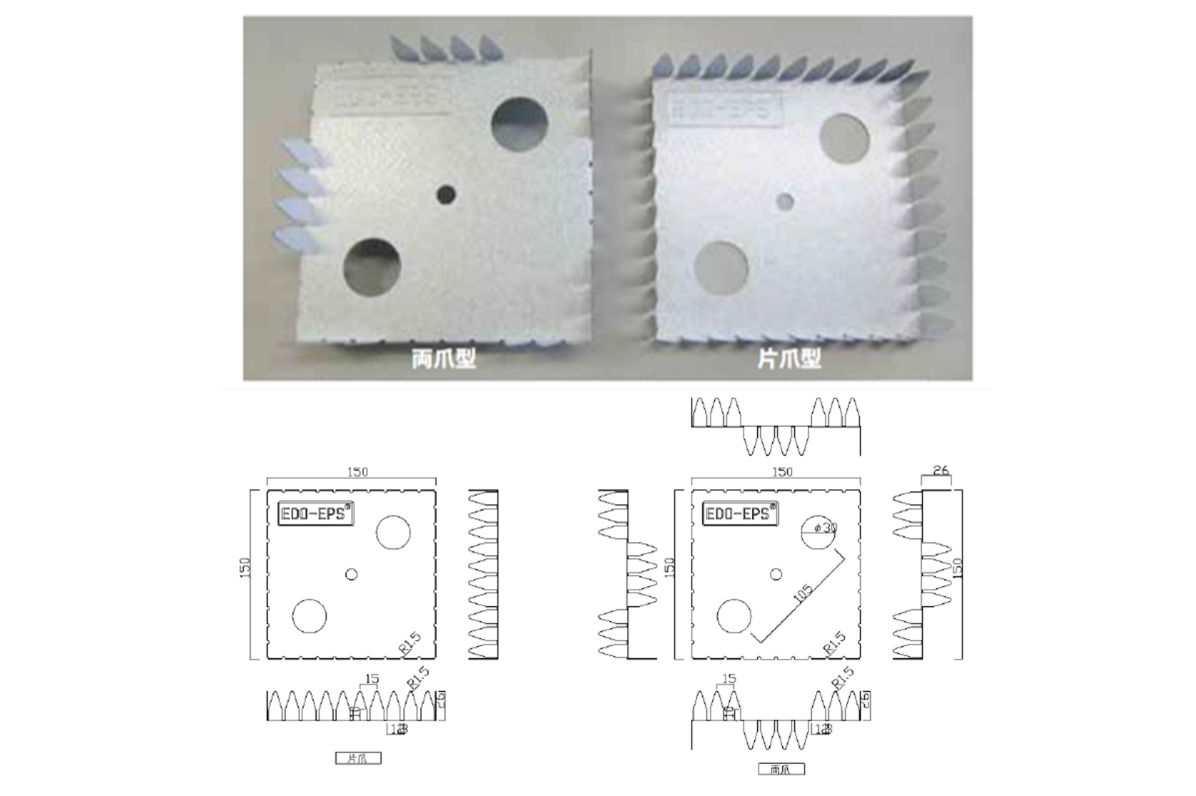

Tightening fittings connect stacked mutual tough blocks to prevent lateral misalignment and are important components to satisfy the effect of seismic resistance.

Tightening fittings are available in double-claw and single-claw types.

Double-jawed: Connecting points for tuff blocks in the vertical and horizontal directions (installed between each layer of tuff blocks)

Single jaw type: Where Tough Blocks are connected in the left and right directions only (concrete slab, structure, or other installation surface)

The imprint of “EDO-EPS” is stamped on the surface.

| item | unit | standard value | |||

|---|---|---|---|---|---|

| Dimensions | mm | length | range (e.g. of voice) | Claw Height | thickness |

| -1.0 150.00 +1.5 |

-1.0 150.00 +1.5 |

-1.0 26.00 +1.5 |

0.584 or more | ||

| Tension test | N/mm2 | Yield store 295 min., Tensile strength 400 min. | |||

| Material properties | – | Fused 55% aluminum-zinc alloy plated steel sheet (galvalume steel sheet) | |||

| Mass | g | 145.0±10 | |||

Concrete Canvas (CC) Standard Dimensions

| terms | EDO-EPS block size | quantity | |

|---|---|---|---|

| Level 2 earthquake motion is not considered | Consider level 2 earthquake motion | ||

| per m2 | – | 1 | 2 |

| per m3 | 2.0 x 1.0 x 0.5m | 2 | 4 |

Type/Standard

| item/type | unit | manufacturing method | remarks | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| In-mold foaming method | Extrusion foaming method | ||||||||||

| D-16 | D-20 | D-25 | D-30 | DX-24H | DX-29 | DX-35 | DX-45 | ||||

| Unit weight | kN/m2 | 0.16 | 0.20 | 0.25 | 0.30 | 0.24 | 0.29 | 0.35 | 0.45 | (JIS-K-7222) | |

| Allowable compressive stress | kN/m2 | 35 | 50 | 70 | 90 | 100 | 140 | 200 | 350 | Compression elasticity region | |

| Quality Control Compressive Stress | kN/m2 | More than 70 | 100 or more | 140 or more | 180 and above | More than 200 | 280 or more | More than 400 | More than 700 | At yield strain or 10% strain (JIS-K-7220) | |

| Dimensions | Length (L) | mm | 2000(±11) | 2000(±11) | – | ||||||

| Width (W) | mm | 1000(±7) | 750(±6) | ||||||||

| Thickness (t) | mm | 500(±4) | 100(±2) | ||||||||

| Usage | – | Sidewalks, etc. | Road embankment, etc. | – | |||||||

| Flammability | – | flame resistance | JIS-A-9521:2017 | ||||||||

Blocks of the extrusion foaming method can be bonded together with a special adhesive to change their thickness. 5 blocks can be bonded together to match the shape of the in-mold foaming method.

Note: The above values are standard values.

Usage