Membrane inspection scaffold

Contributing to the function of inspection scaffolds on bridges and to the aesthetic effect and longevity of bridges by wrapping them in membrane material.

Wrapping the bridge with the membrane gives it a clean appearance, while the soft texture of the membrane material provides a sense of security.

In addition, by attaching the membrane material between and on the sides of the main girders of the bridge, the membrane surface can be used as an inspection scaffold. (NETIS: KK-190030-A Membrane-type inspection scaffold) (Metropolitan Highway Technical Registration: Bridge exterior membrane construction method)

Related Achievements

Product & Service

Features

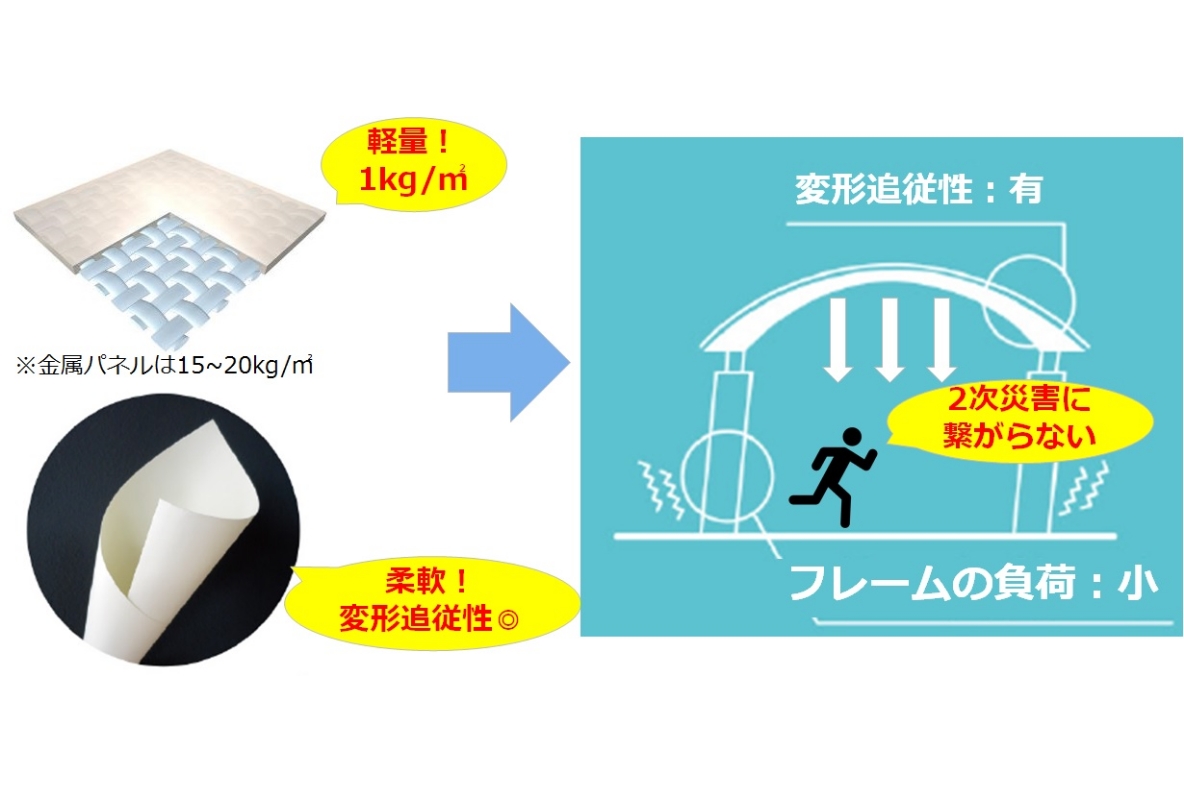

Safety and Security

Lightweight and flexible, membrane materials can significantly reduce the load burden on the bridge body compared to other materials. They also have excellent deformation-following properties and safety features that reduce the risk of secondary disasters such as falling members.

Long life

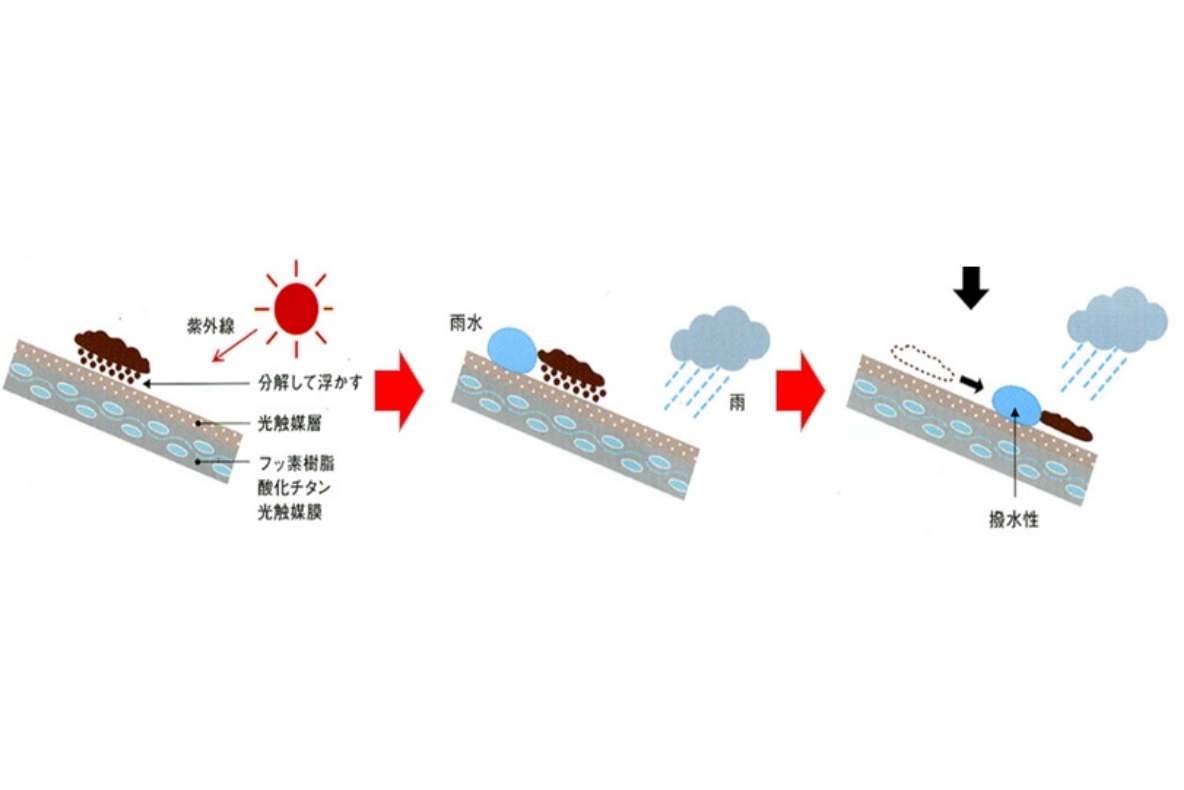

Membrane materials do not rust and do not require painting.

In addition, it is not only used as scaffolding, but also covers the main body of the bridge, preventing corrosion factors (chlorides, etc.) from adhering to it and contributing to the longevity of the structure. In addition, the titanium dioxide photocatalyst treated membrane material exhibits a “self-cleaning function” that uses sunlight (ultraviolet rays) and moisture in the air to decompose adhered dirt.

Light/brightness

The membrane is a very thin material that transmits light from outside to brighten the interior of the digit. (Illuminance is about 200 lx)

The membrane also reflects light (approximately 77% visible light reflection), brightening the entire space under the guard with a dim image.

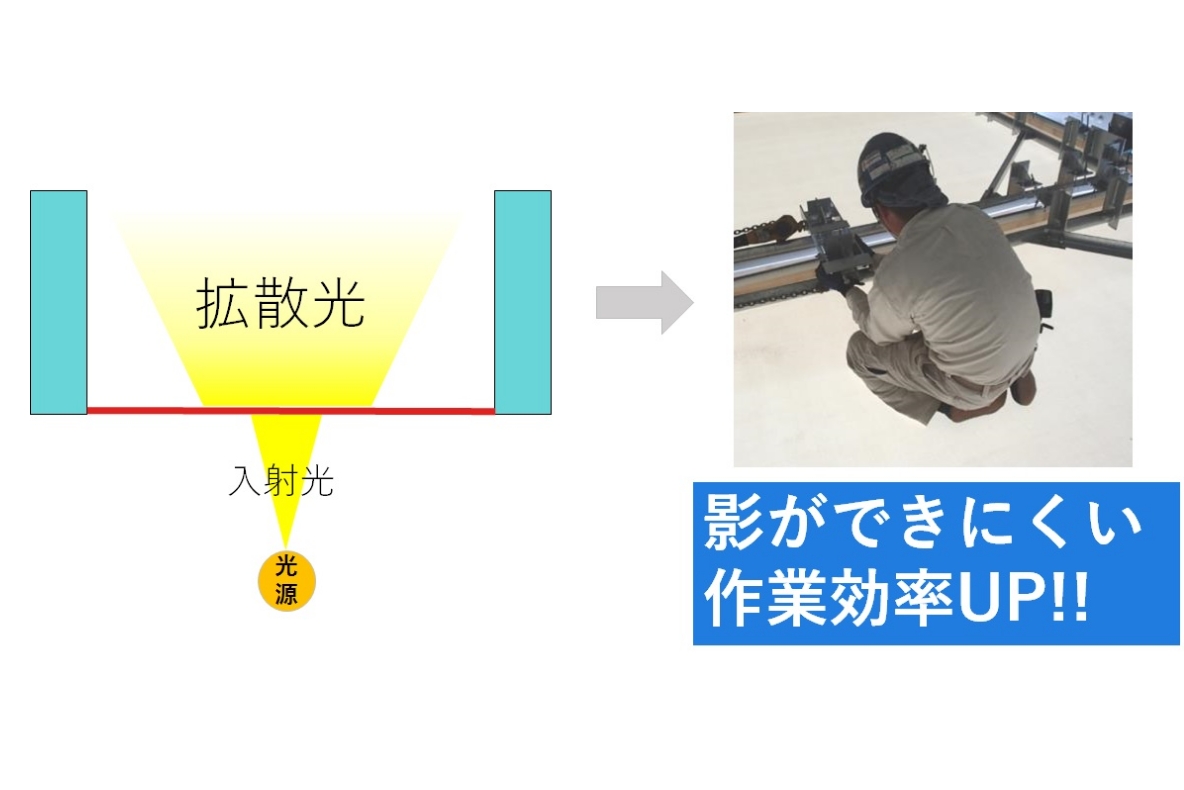

Improved efficiency of maintenance and management

The brighter interior of the girder prevents shading because the transmitted light is diffused, making it suitable for detailed work at hand and increasing work efficiency during inspections.

Others (light-up effects for even more beautiful scenery)

The light and images illuminated by the collaboration of membranes and lighting create shadows that cannot be expressed on a flat surface, and in turn, create a fantastic world. It is also possible to project advertisements and practical information.

Membrane Performance Chart

| Thickness (mm) | Weight (kg) | Visible light transmittance/reflectance (%) | Titanium dioxide photocatalytic film | Noncombustibility/flame retardant performance | variety | Other | |

|---|---|---|---|---|---|---|---|

| Fluoropolymer film agent | 0.8 | 1300 | 12.7/78.5 | symbol used as a placeholder (either because a number of other words could be used in that position or because of censorship) | non-inflammable material | white | Photocatalytic self-cleaning and NOx removal (air purification) performance. |

| PVC film agent | 0.55 | 785 | 12.0/76.7 | symbol used as a placeholder (either because a number of other words could be used in that position or because of censorship) | non-inflammable material | White (option: coloring/printing) | |

| ETFE Film | 0.33 | 577 | 92.3/7.6 | – | Acquired 1st class flameproof

Obtained DW certification |

Transparent (option: coloring/printing) | The material is transparent like glass, yet lightweight, soft, and safe. |

*Other membrane materials are available. Please consult us.