Concrete Canvas

A thin, highly durable, watertight, and fire-resistant concrete surface can be created simply by applying water.

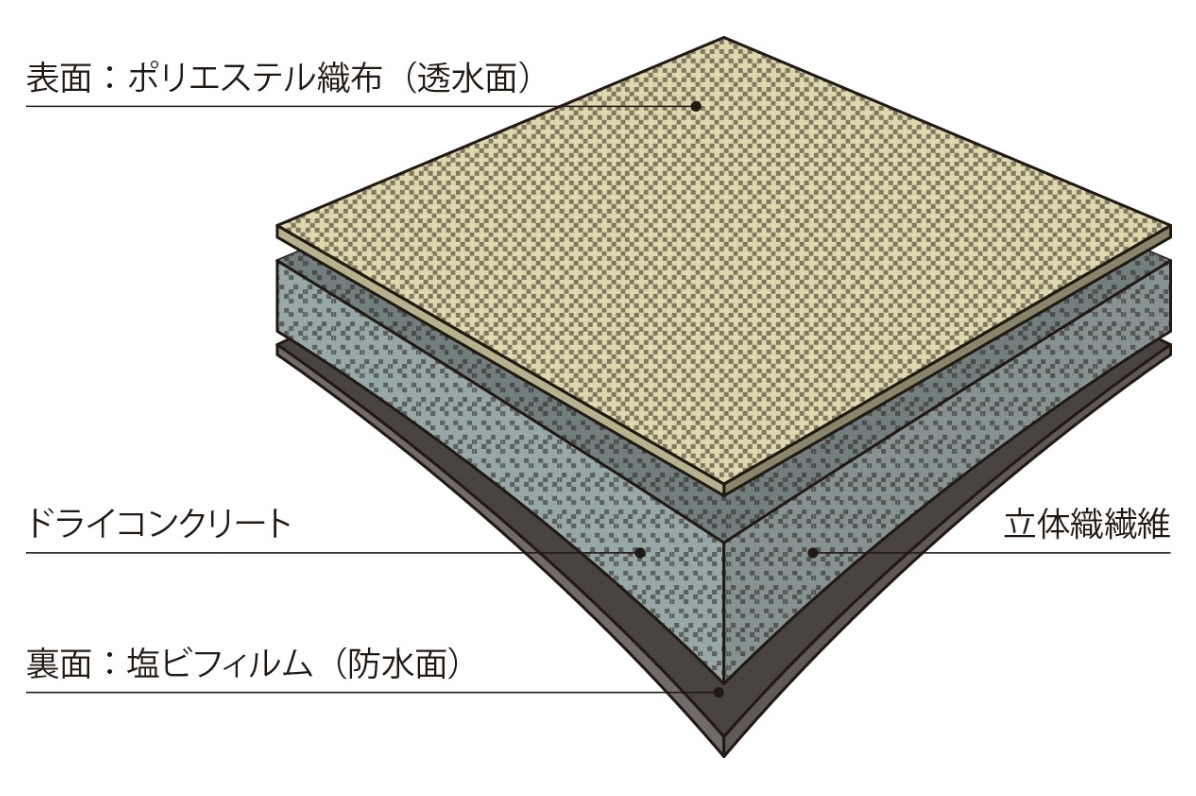

The structure consists of specially formulated dry concrete sandwiched between a three-dimensional canvas (woven fiber matrix) and PVC sheeting. After laying, the dry concrete begins to cure by sprinkling water or immersing it in water. A thin, highly durable, fire-resistant concrete surface can be constructed.

New Technology Information System “NETIS Registration” : Concrete Canvas Method

Registration No. CG-220009-A

Related Achievements

Product & Service

Feature

High workability

The only materials needed to construct the concrete surface are concrete canvas and water.

No heavy equipment or special skills are required for on-site casting. There is no need for measuring or mixing, and there is no excess water. Underwater installation and hydration with seawater are also possible.

You can choose between “batch rolls,” which can be transported by hand, and “bulk rolls,” which can be installed at high speed on a large scale using heavy machinery. High strength and low elongation.

Excellent ground followability

Flexible before curing and conforms to complex shapes (fine-tuning is possible for 1-2 hours after hydration starts)

Easy installation by ordinary workers

No special tools or special workers are required, and the only heavy equipment needed is heavy equipment for unloading.

Can be installed underwater and in the rain

Hydrates and cures in both freshwater and seawater, and can be installed underwater or in the rain

Storage is also available

Can be stored for up to 2 years from the date of manufacture by controlling humidity.

Durability

It is chemically and weather resistant and does not deteriorate due to ultraviolet rays.

Environmentality

The greatest feature is the limited amount of free alkali and low abrasion, which minimizes the impact on the local ecosystem. Otherwise, Concrete Canvas is an environmentally friendly product.

Reduction of CO2

Concrete canvas is the only method of laying a thin layer of concrete from a roll of ready-made material. When used as a thin surface material, such as for weed control, it can replace as little as 4.5 to 8 mm of cast-in-place concrete, compared to 50 to 150 mm required by conventional methods. As a result, material savings of up to 95% can be achieved for a typical construction project. This directly reduces the CO2 emissions of the construction operation, not only through material savings, but also in terms of road transport and time spent on site.

Low free alkali

Concrete Canvas uses a special fast-strength concrete with a limited amount of free alkali. Unlike most concrete, this product is not classified as an irritant and is not harmful to the environment.

EA Approval (UK)

The use of concrete canvas was approved by the Environmental Authority (EA) Biodiversity Team for the Church Village Bypass project in 2010. The advantages of the canvas include “a rougher surface that adds diversity to the channel morphology” and the ability to introduce “curvature to the channel flow path. Since then, several projects have been approved on a case-by-case basis, with the most recent being a direct purchase by the EA for use within the EA as weed control.

Fire resistance

Concrete canvas is fire retardant, which means that flames do not spread to the surface, keeping smoke production low and the emission of toxic gases to a minimum.

Depending on the application, it can be used as a fire protection layer and has achieved Euro Class B according to BS EN 13501 flame reaction tests.

The concrete canvas has also been approved by the U.S. Mine Safety and Health Administration (MSHA) as meeting 30 CFR Part 7, Section B, Section 7.24.

Main components and installation procedures

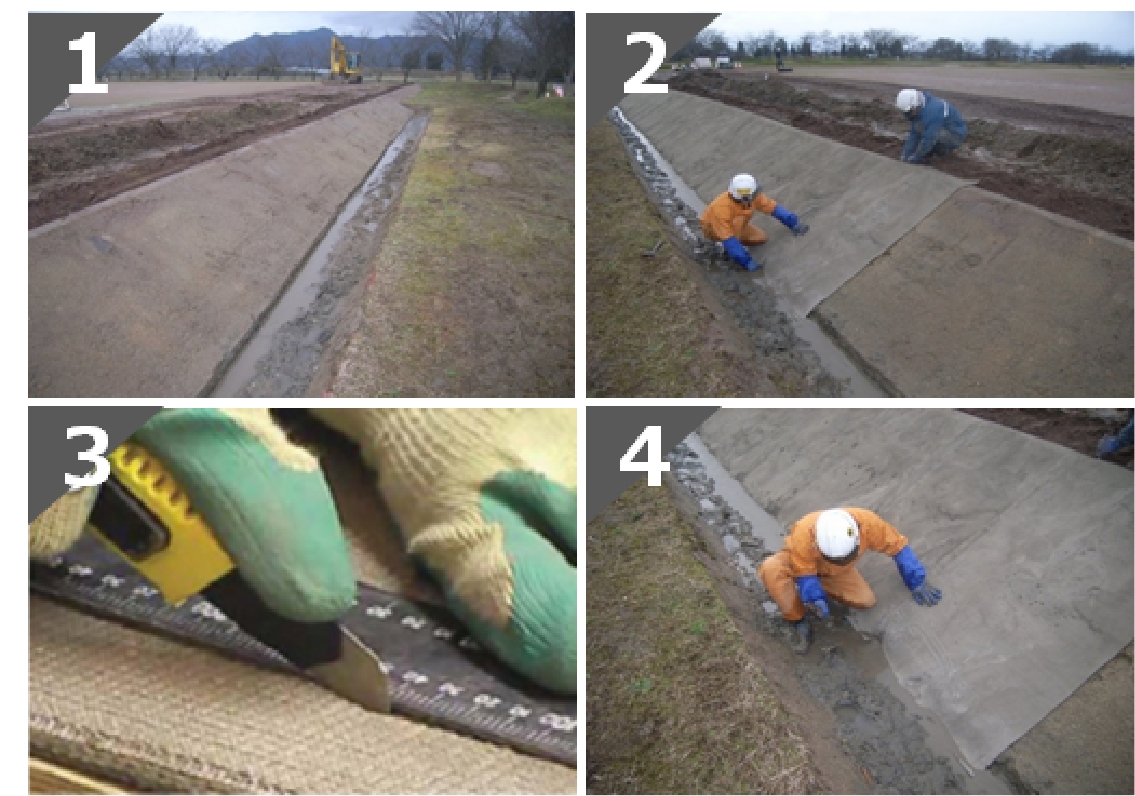

Establishment

1. rocks, stumps, and other protrusions that could cause damage should be removed in advance. Concrete canvas blends well with the ground shape. Ground shaping is essential for a beautiful finish.

2. Spread the concrete canvas in place with the PVC sheet on the underside. When laying continuously, allow at least 100 mm overlap allowance. Also, if there is a water flow, all joints should be in the direction of the flow.

3. cut and process the concrete canvas as needed. If it is before hardening, it can be cut by ordinary cutters or disc cutters.

4. anchor pins, etc., to secure the concrete canvas. The type and pitch of pins are determined according to the ground conditions and slope.

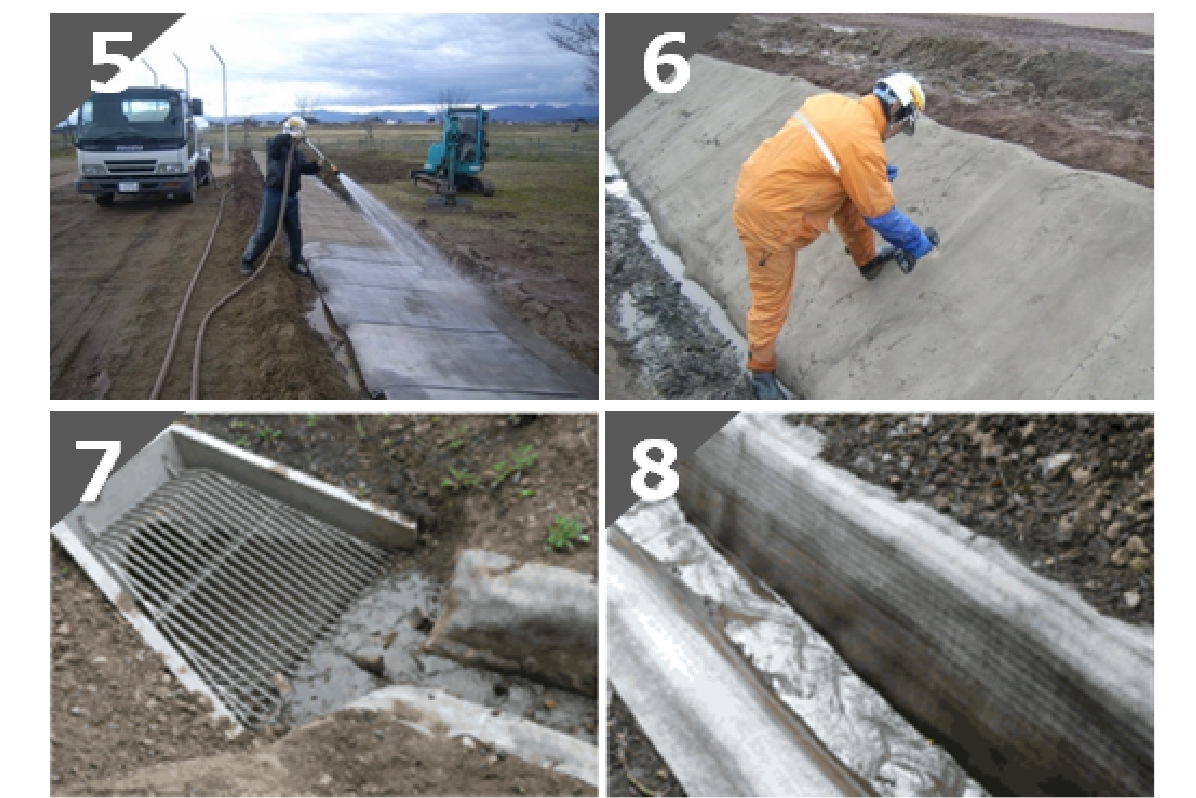

Hydration

After installation is complete, hydrate the concrete canvas by sprinkling water or other means (seawater is acceptable). (Seawater is also acceptable.) Depending on the situation, watering may be performed again after one hour.

6. bond the overlapped concrete canvases with wood screws, etc. Adhesive sealant is also used depending on the application.

7. the CC before curing is very flexible and can easily be connected to the square and the end points can be easily processed.

8. Concrete canvas does not begin to harden for approximately 2 hours once the hydration reaction has begun, allowing for adjustment (tends to be shorter in tropical regions). Concrete canvas cures quickly, increasing strength to 80% of its 10-day strength in 24 hours.

Standard dimensions

Concrete Canvas (CC) Standard Dimensions

| stock number | Thickness (mm) | Length | Width (m) | Weight when not cured (kg/m2) | |

|---|---|---|---|---|---|

| batch-roll | bulk roll | ||||

| CCT1 | 4.5(-0.0/+1.0) | 9.5(-0.0/+1.0) | — | 1.0(-0.02/+0.07) | 7.0 or higher |

| CCT2 | 7.0(-0.0/+2.0) | 4.3(-0.0/+0.5) | — | 1.1(-0.03/+0.03) | 10.5 or higher |

| CCT3 | 10.0(-0.0/+3.5) | — | 72(-0.0/+2.0) | 1.1(-0.03/+0.03) | 18.5 or higher |

Only batch rolls of CCT1/2 are in stock in Japan. Others will be imported from the U.K. after receiving an order.

| Compressive strength | Bending strength | Coefficient of roughness | Friction resistance | ||

|---|---|---|---|---|---|

| 80 MPa or higher | 4.0 MPa or higher | 0.011 | 0.15mm/1000cycles | ||

Passed various performance tests such as fire resistance and freeze damage resistance in accordance with British Standards. *Compressive strength indicates 28 days of lumber age, and bending strength indicates 1 day of lumber age.

*The above figures are not guaranteed values.

Usage

Concrete canvas is used in a variety of locations for its unique performance.

Disaster recovery (sandbag covering)

Erosion prevention (surface protection)

Waterway maintenance and expansion

Irrigation channel construction

Weed prevention

| use | CCT1 (CC5) | CCT2 (CC8) | CCT3 | Filter type |

|---|---|---|---|---|

| Waterway Lining | 〇 | ◎ | 〇 | CCT2 (CC8) is recommended if any of the following conditions are not met Use CCT1 (CC5) for surface repair protection of existing concrete channel works and rock or other hard substrates, or for temporary works. Use CCT3 when flow velocities exceed 8.6 m/s, on ground with vehicular traffic, or on particularly unstable or steep slopes. |

| Slope protection | ◎ | 〇 | – | CCT1 (CC5) is recommended. CCT2 (CC8) can be used for unstable ground or high flow rates. |

| Weir lining | ◎ | 〇 | 〇 | CCT1 (CC5) is recommended. CCT2 (CC8) or CCT3 can be used in high traffic areas. |

| Concrete Repair | ◎ | 〇 | 〇 | CCT1 (CC5) is recommended. For larger cavities or applications with high flow rates or turbulence, CCT2 (CC8) or CCT3 can be used. |

| Culvert lining | 〇 | ◎ | 〇 | CCT2 (CC8) is recommended. CCT3 can be used where there is a lot of earth and rocks or in conditions with high flow velocities. CCT1 (CC5) can be used in conditions of low flow velocity or low soil and rock. |

| Weed prevention | ◎ | 〇 | – | CCT1 (CC5) is recommended. CCT2 (CC8) is recommended when walking on concrete canvas for maintenance, etc. |

| Outlet/residual water discharge | – | ◎ | 〇 | CCT2 (CC8) is recommended. Use CCT3 for earth and rock laden drop-offs and high flow rates. |

| Basket protection/ large sandbag protection |

◎ | ◎ | 〇 | CCT1 (CC5) or CCT2 (CC8) is recommended. CCT3 can be used where flow velocities are high or where there is exposure to shock. |

| Ventilation Tunnel Wall/Protective Wall | ◎ | ◎ | 〇 | CCT1 (CC5) is recommended for the ventilation tunnel wall. For protective walls, CCT2 (CC8) is recommended depending on the pressure applied. |