"Silt Protector"

-Pollution control membrane-

We propose the most suitable anti-pollution membrane based on our industry-leading track record.

Pollution control membrane is a structure installed to prevent the diffusion of pollution generated during dredging and reclamation works on public water surfaces, mainly in the ocean. In Japan, we have over 40 years of experience in the field of anti-pollution membranes, and the technology has matured through our experience in the field.

Sludge and silt polluted water spreading in port and other water area construction projects is a major obstacle to environmental preservation. The Silt Protector, developed to prevent such pollution, can be used in a wide range of installation conditions, from calm waters to rough seas.

*For sale only in the Japanese market

Related Achievements

Products & Services

Feature

The silt protector is an indispensable anti-pollution system in marine planning.

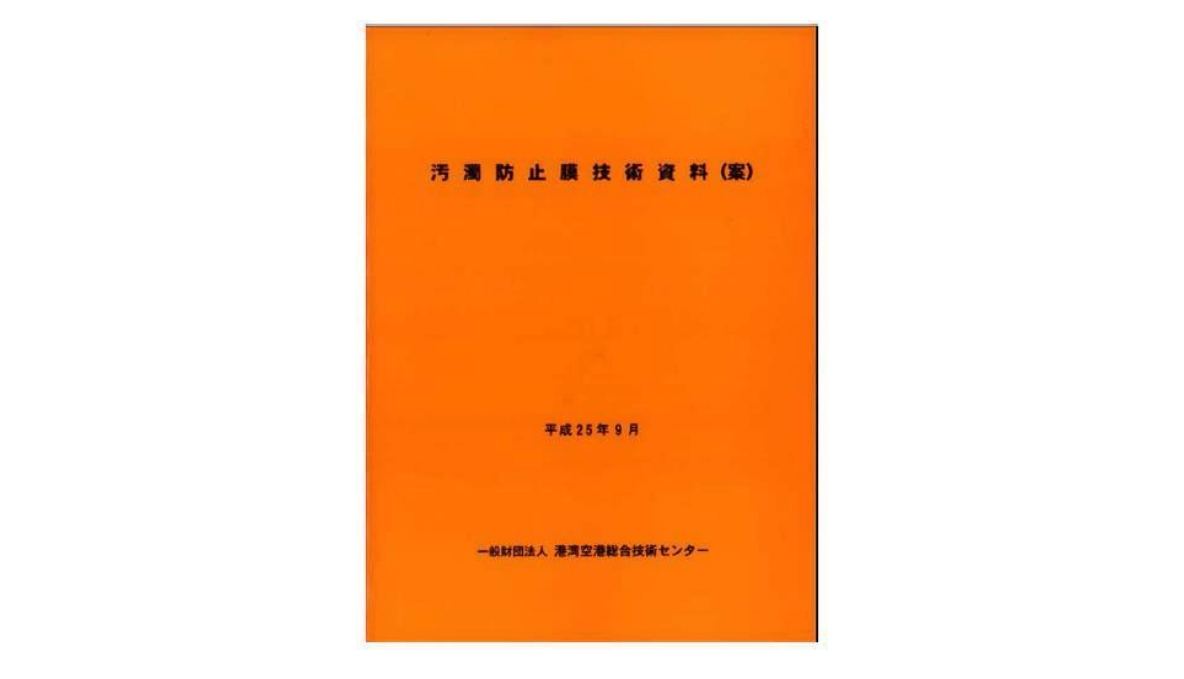

In response to the recent shift to performance-based technical standards, “Draft Technical Data on Pollution Control Membranes” was published in September 2013 and posted on the website of the Port and Airport Research and Development Center (PARC) to make it widely known to all those involved in offshore construction.

This draft technical document summarizes the standard approach to design, fabrication, quality control, installation, maintenance, removal and reuse of anti-pollution membranes. Particular attention is paid to performance verification, quality control, and maintenance. In recent years, the reuse of anti-pollution membranes is strongly recommended to reduce construction waste. The book also details performance verification, quality control, and maintenance management methods for reused anti-pollution membranes (rental products), which have not been clearly defined in the past.

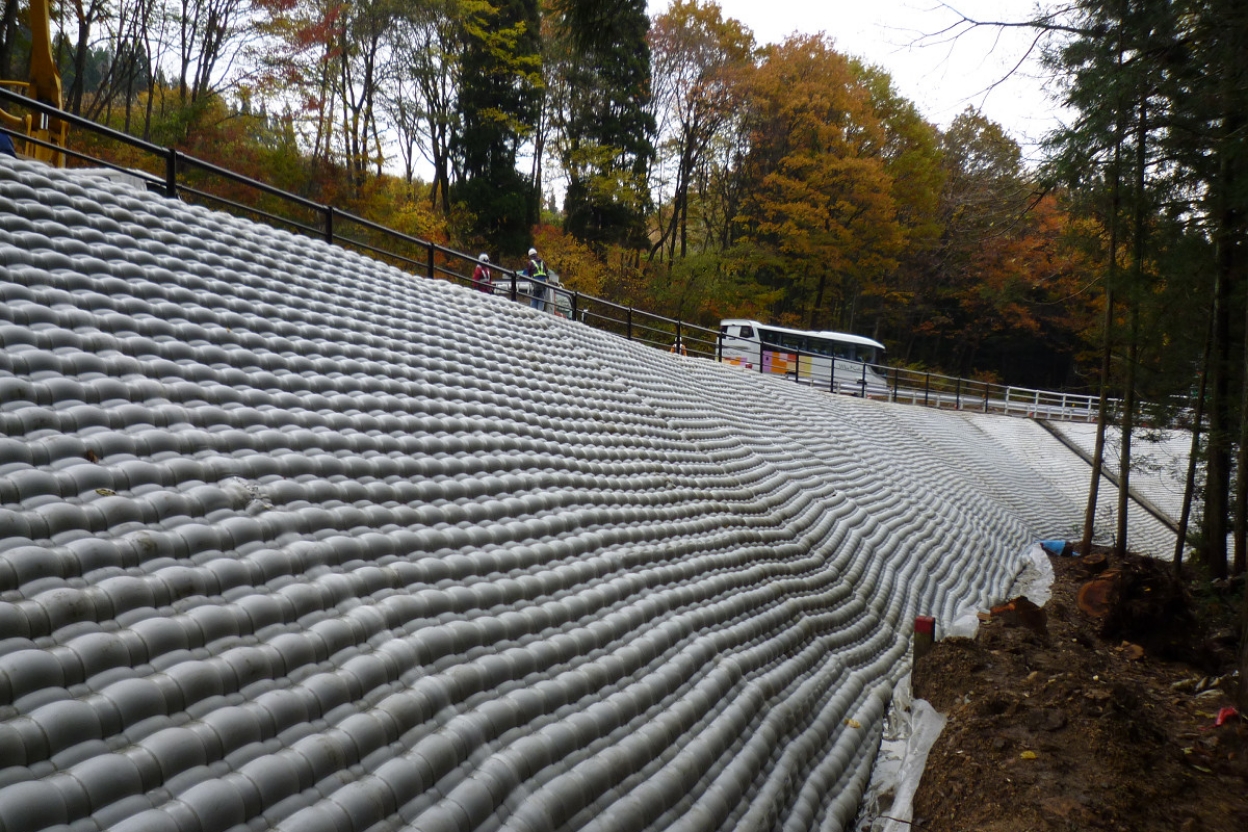

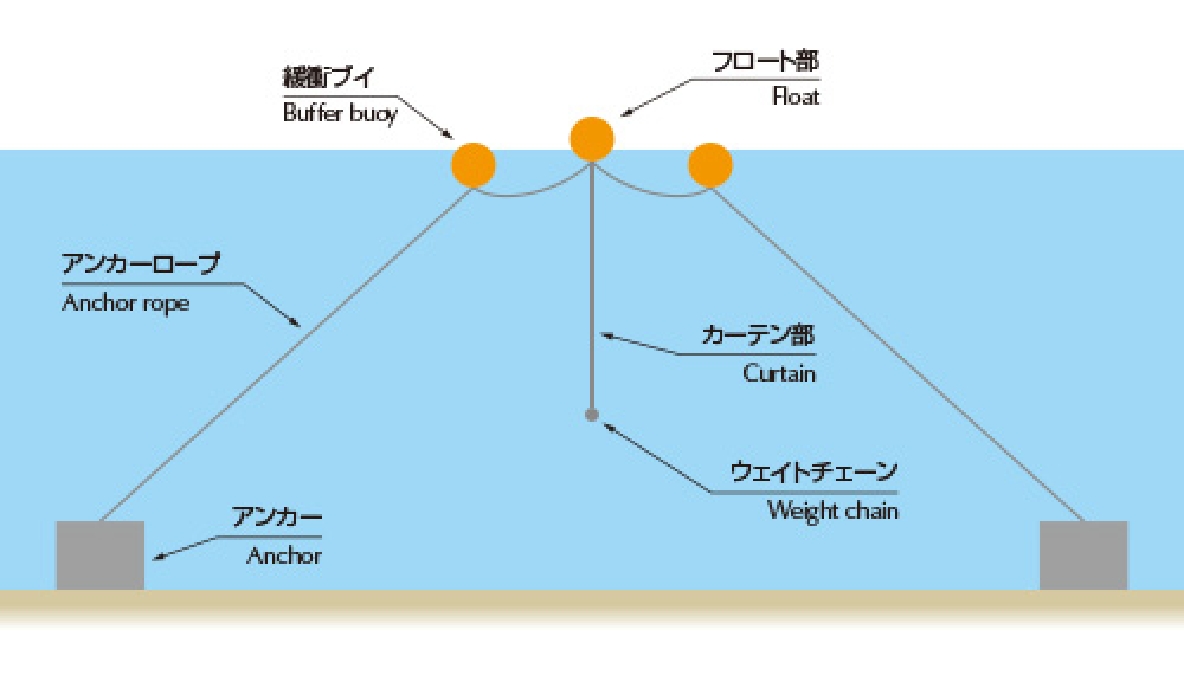

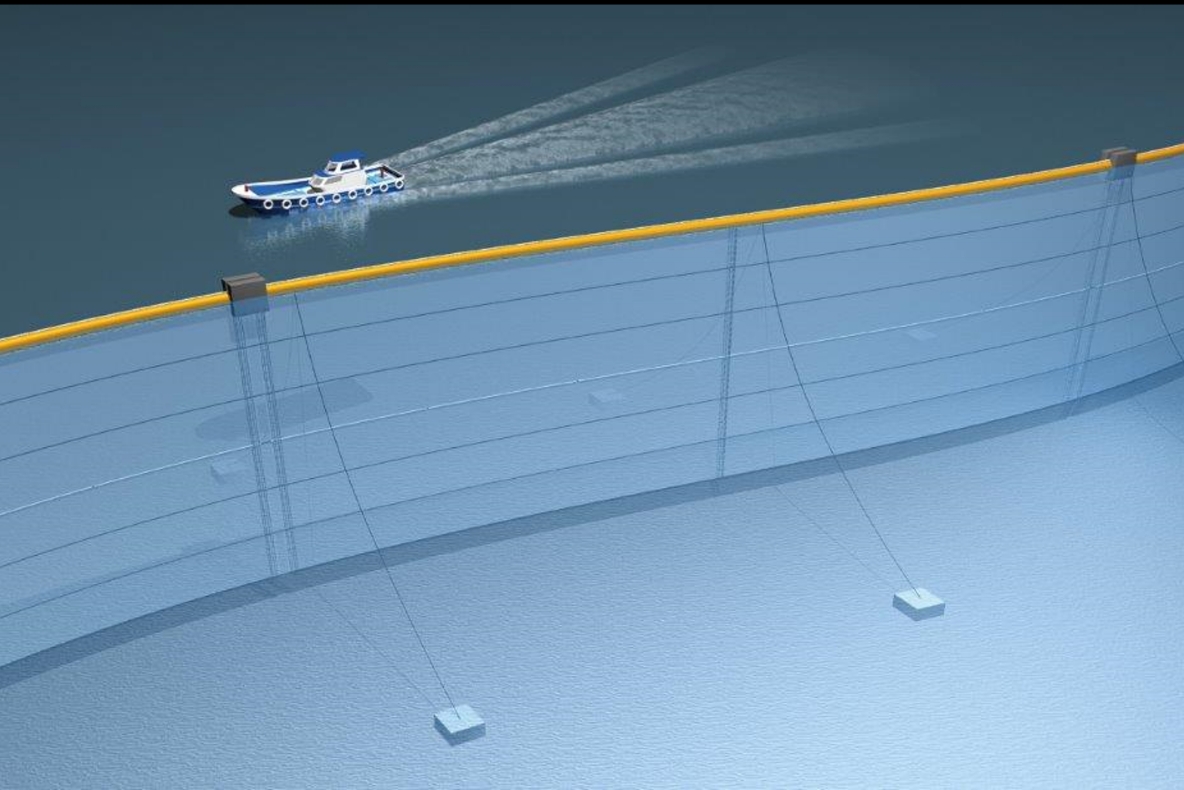

Fixed hanging type anti-pollution membrane

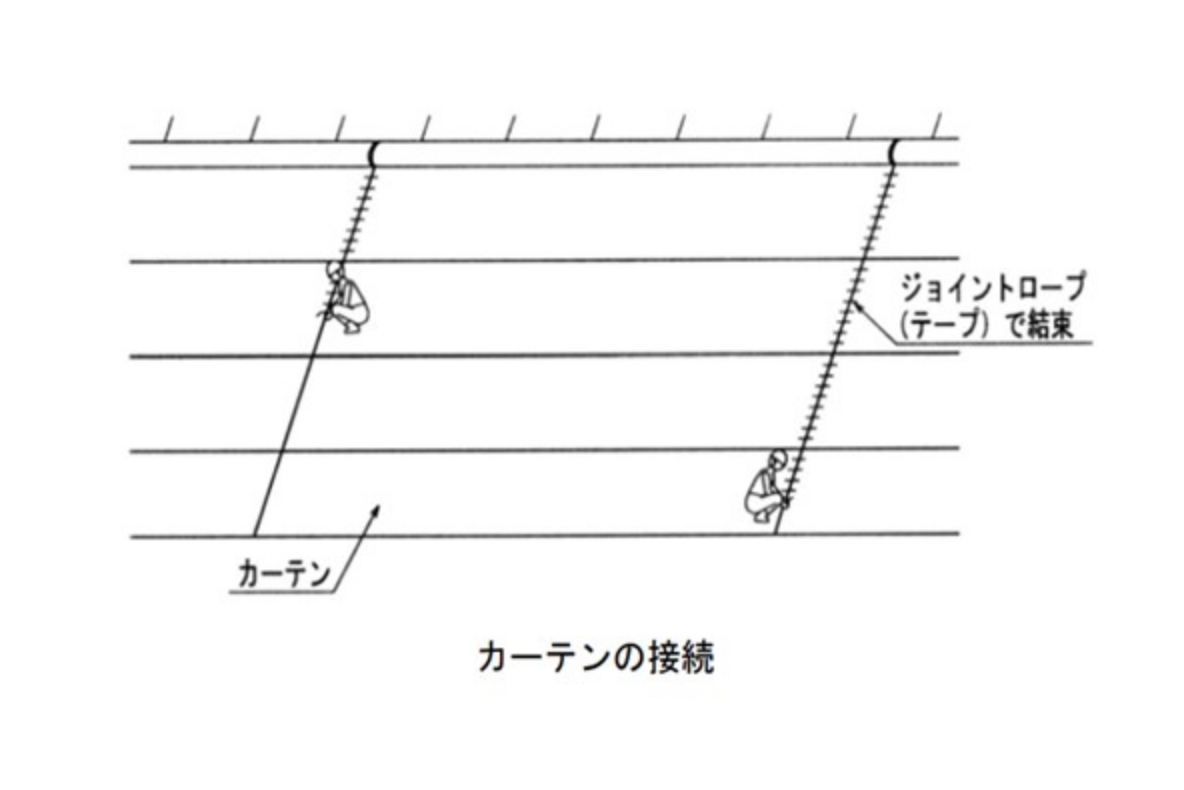

The fixed hanging type is the most commonly used type in which the curtain part is lowered into the water from the float part floating on the water surface.

The mooring section is used to stabilize the anti-pollution membrane horizontally by mooring force, and consists of an anchor rope to moor the membrane and an anchor to fix it to the seabed. Wire rope or synthetic fiber rope is used for the anchor rope. Anchors must also satisfy the required resistance force, and durability and corrosion resistance must also be considered.

Cushioning buoys are sometimes used to avoid contact between the curtain and the anchor rope, to reduce the weight of the anchor rope acting on the tension section, and to absorb shock when an impact pulling force is applied.

Standard Specifications of Products for Sale (Fixed Drooping Anti-Pollution Membrane)

| Type | Installation site conditions | Specification | |||

|---|---|---|---|---|---|

| Float diameter (mm) |

Float format | Curtain fabric (No. of hands) |

Weight chain mass (kg/m) |

||

| A | Significant wave height: 1.5 m or less, current velocity: 0.5 m/s or less (the waters outside the breakwater, shielded by natural terrain) |

600 | consecutive | 800-500 | 10 to 20 |

| B | Significant wave height: 1.0 m or less, current velocity: 0.2 m/s or less (large areas of water within the breakwaters, or in the depths of the bay, shielded by natural topography) |

400 | consecutive | 500-300 | 5 to 10 |

| C | Significant wave height: 0.8 m or less, current velocity: 0.1 m/s or less (a moderately extensive area within the breakwater) |

300 | consecutive | 500-300 | 5 to 10 |

| D | Significant wave height: 0.5 m or less, current velocity: 0.05 m/s or less (lakes, or sufficiently sheltered deep bay waters that are as quiet as lakes) |

300 | single | 300 | 3-5 |

1. In the continuous type, the buoyant elements are continuously arranged in the float section. The stand-alone type is one with discontinuous buoyant elements.

2. Special specifications are available for waters with significant wave heights exceeding 1.5 m.

3. In selecting the above specifications, the following values are typically used for wind speed, water depth, and curtain length.

Wind speed: 20 m/s, water depth: 20 m, curtain length: 10 m

Standard Specifications for Rental Products (Fixed hanging type anti-pollution membrane)

In September 2013, the rental quality regulations in the draft Pollution Control Membrane Technical Document were revised. It recommends the reuse of pollution control membranes and defines the strength of curtain articles to ensure quality. It also mentions strength certification by a third-party organization.

| Type | Float section specifications | ||

|---|---|---|---|

| Float diameter (mm) | Float format | ||

| Fixed type | Significant wave height: 1.5 m or less, current velocity: 0.5 m/s or less (the waters outside the breakwater, shielded by natural terrain) |

separate consideration | separate consideration |

| Significant wave height: 1.0 m or less, current velocity: 0.2 m/s or less (large areas of water within the breakwaters, or in the depths of the bay, shielded by natural topography) |

φ400 (buoyancy: 980 N/m) | Continuous (Styrofoam float) | |

| Significant wave height: 0.8 m or less, current velocity: 0.1 m/s or less (a moderately extensive area within the breakwater) |

φ300 (buoyancy 294N/m) | Continuous (Styrofoam float) | |

| Significant wave height: 0.5 m or less, current velocity: 0.05 m/s or less (lakes, or sufficiently sheltered deep bay waters that are as quiet as lakes) |

φ300 (buoyancy 294N/m) | Continuous (Styrofoam float) | |

| Floating-sediment type | outside a port or harbor (harbour) | φ600 (buoyancy 2532 N/m) | Continuous (air float) |

| For port and passage gate | φ400 (buoyancy: 980 N/m) | Continuous (air float) | |

In the continuous type, the buoyant elements are arranged continuously in the float section. The stand-alone type has discontinuous buoyant elements.

2. The above installation conditions are only a guide and will vary depending on wind speed, water depth, curtain length, etc.

*Curtain strength is calculated based on the “Pollution Control Curtain Tensile Strength Evaluation System”. Curtain strength is calculated based on the “Pollution Control Membrane Reuse Curtain Tensile Strength Evaluation System.

We have installed tensile testers in our rental shipping yards to check curtain residual strength through sampling. IC tags are attached to the curtains to enable us to check the installation history at all times. By managing rental products of anti-pollution membranes with sufficient technical know-how, we continue to maintain a reliable supply system in terms of quality and inventory.

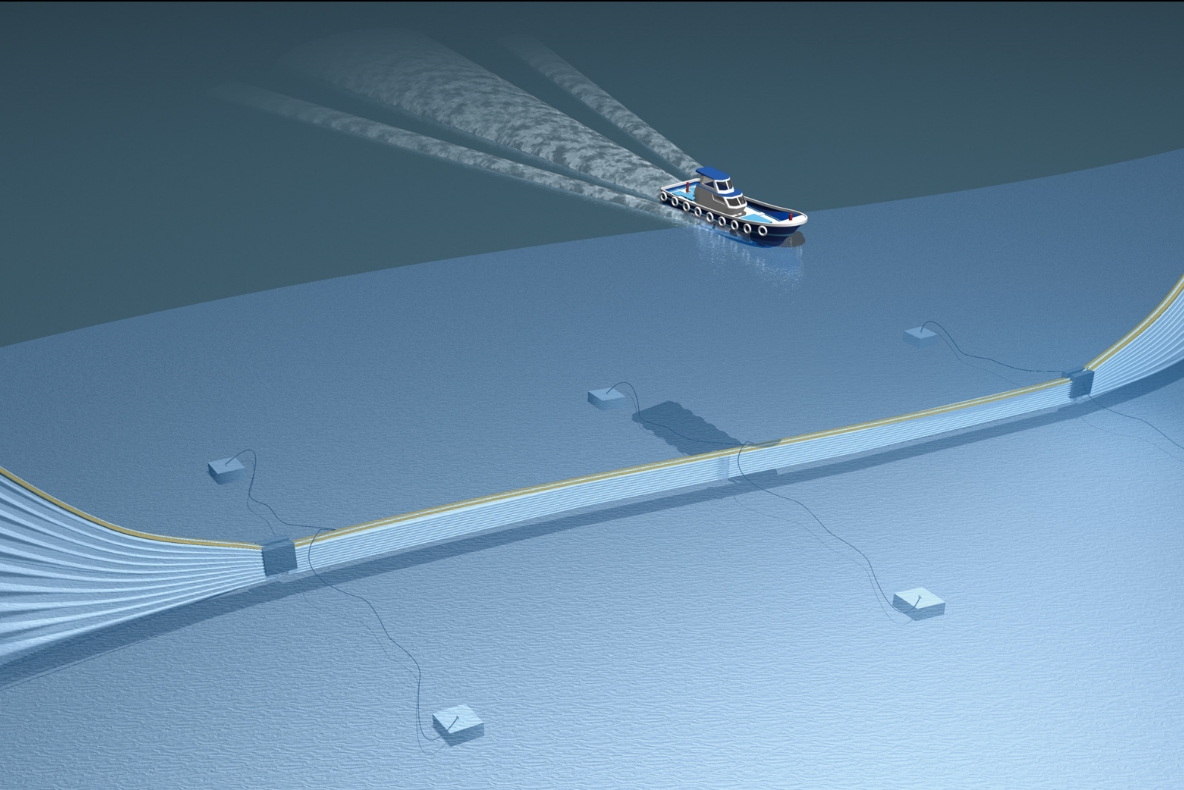

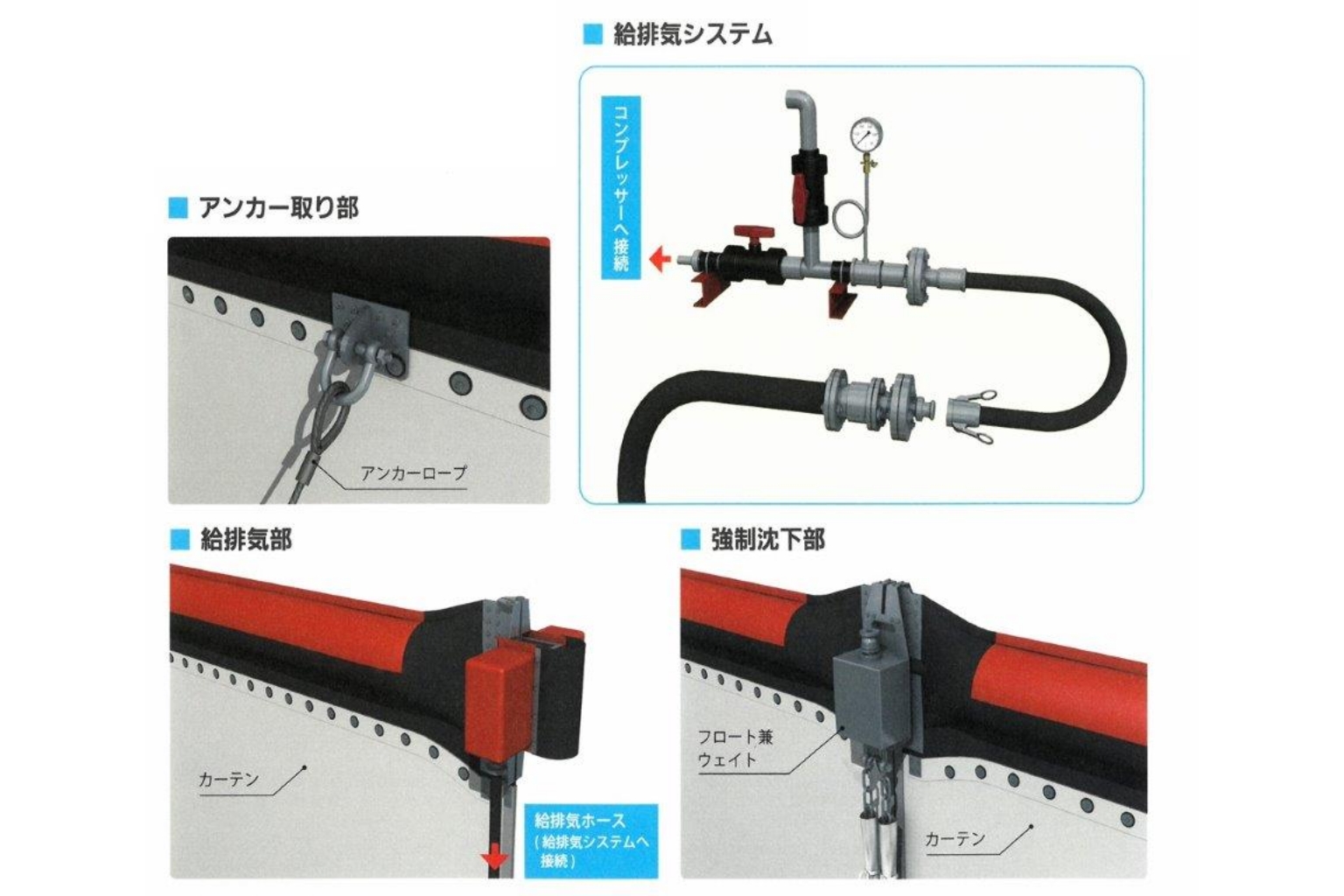

Floating type hanging form anti-pollution membrane

Floating type hanging form is a type of anti-pollution membrane that has a hanging curtain and a float section that can float or sink.

Moorings consist of anchor ropes and anchors, buffer buoys are often used, and concrete blocks are often used as anchors for moorings.

surfacing moment

during sinking

The float part is made of synthetic rubber and can be raised or lowered by inserting or removing air in the float. The cross-sectional structure of the floating type is the same as that of the fixed hanging type. For connection between floating and sinking type anti-pollution membranes, mounting fittings are used together with supply and exhaust piping.

The float of Taiyo Kogyo’s floating silt protector can be selected between a conventional one-chamber structure and a more reliable two-chamber structure. and durability.

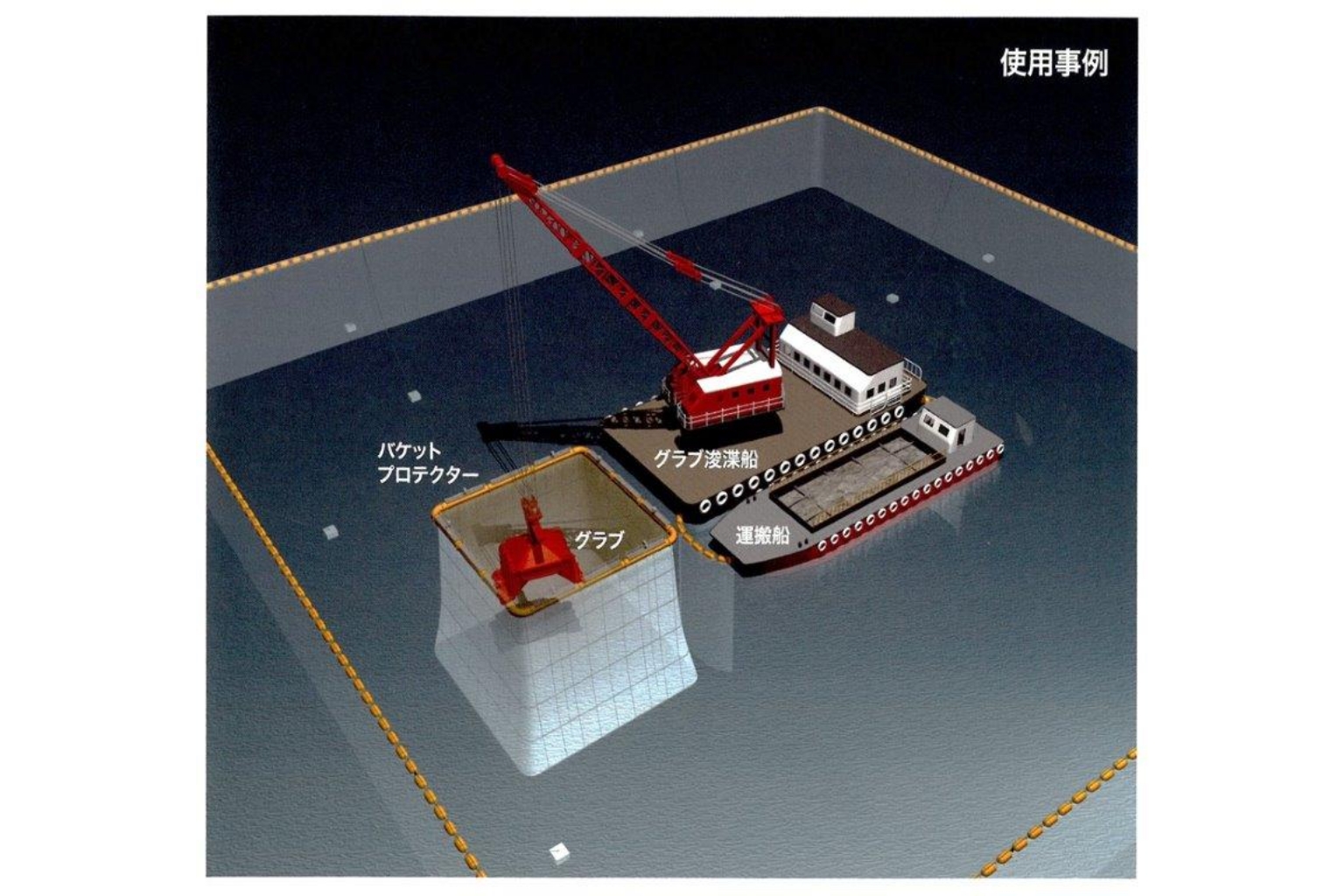

Bucket Protector” frame-type anti-pollution membrane (anti-pollution frame)

The frame type is a type of anti-pollution membrane with a curtain part hanging down from the bottom of a float part made of steel pipe, etc. It is used in dredging operations by grab dredgers, etc. to prevent partial pollution at dredging points. It is used for partial pollution prevention of dredging area in dredging operation by grab dredger.

The curtain section of a framed anti-pollution membrane must be sufficiently secure against the tension forces generated. In addition, performance verification must be performed for the actions that occur in the curtain section.

Construction Procedures and Structural Calculations

Construction

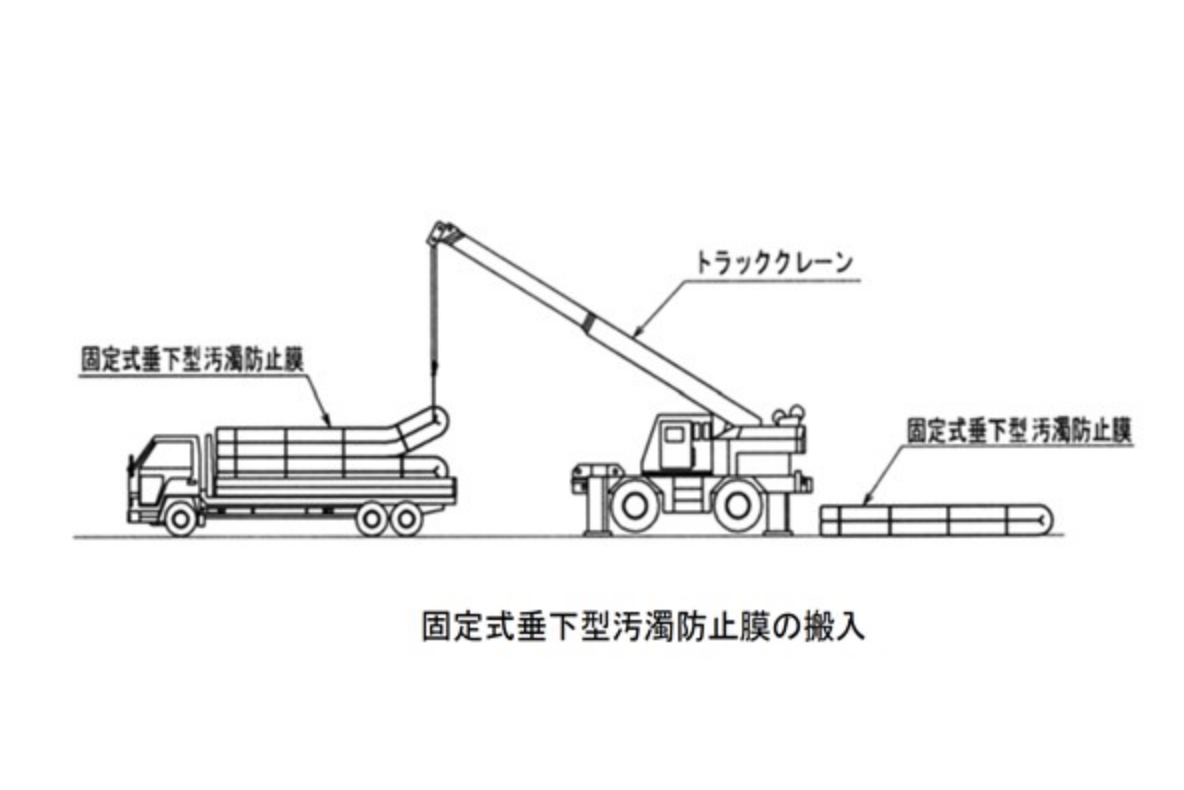

Preparatory operations

- clear work yard

- anchor block production

- delivery of materials

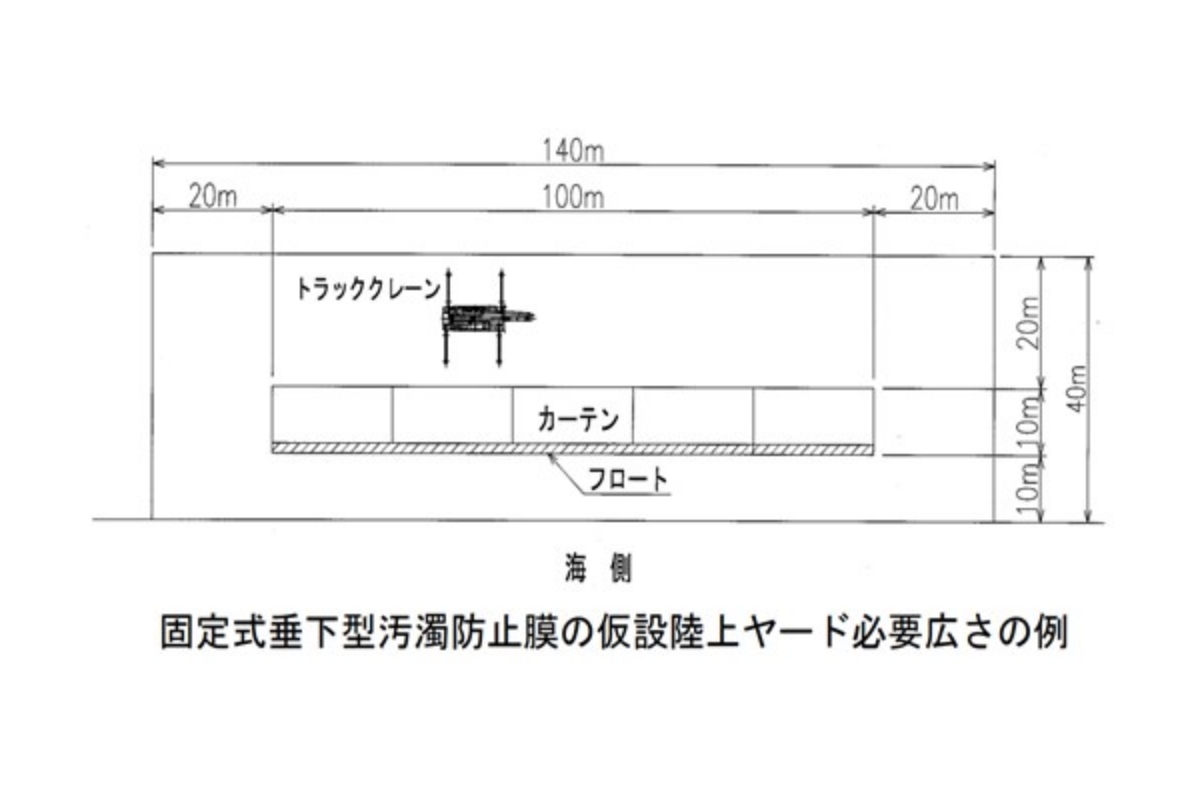

For the onshore work yard, a site of 120m to 140m X 40m is required for easy assembly and unloading.

Onshore assembly operations

- examination

- vertical joints between spans

- temporary fixing of curtains

Upon completion of all assembly and connection work in the hypothetical land yard, product and mooring inspections are conducted to ensure that there are no defects.

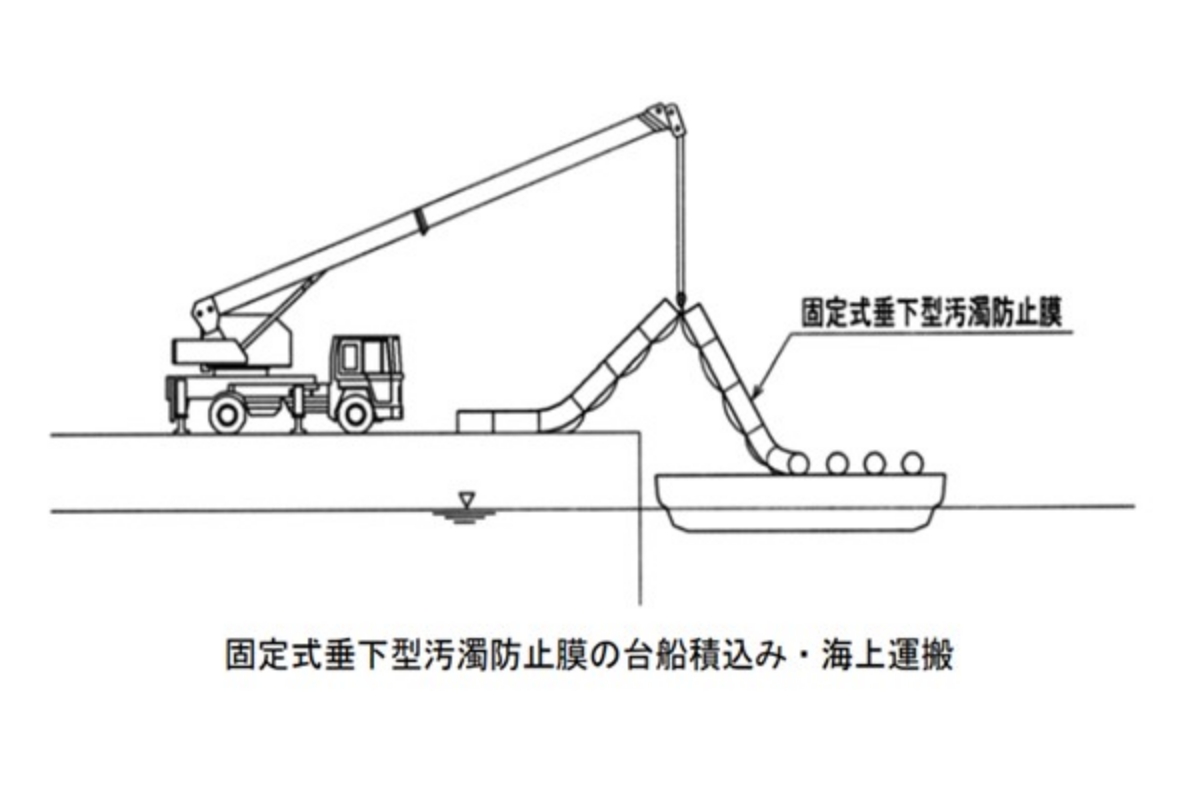

Offshore installation work

- barge loading

- towing (a ship)

- anchor block installation

- installation of anti-pollution membrane

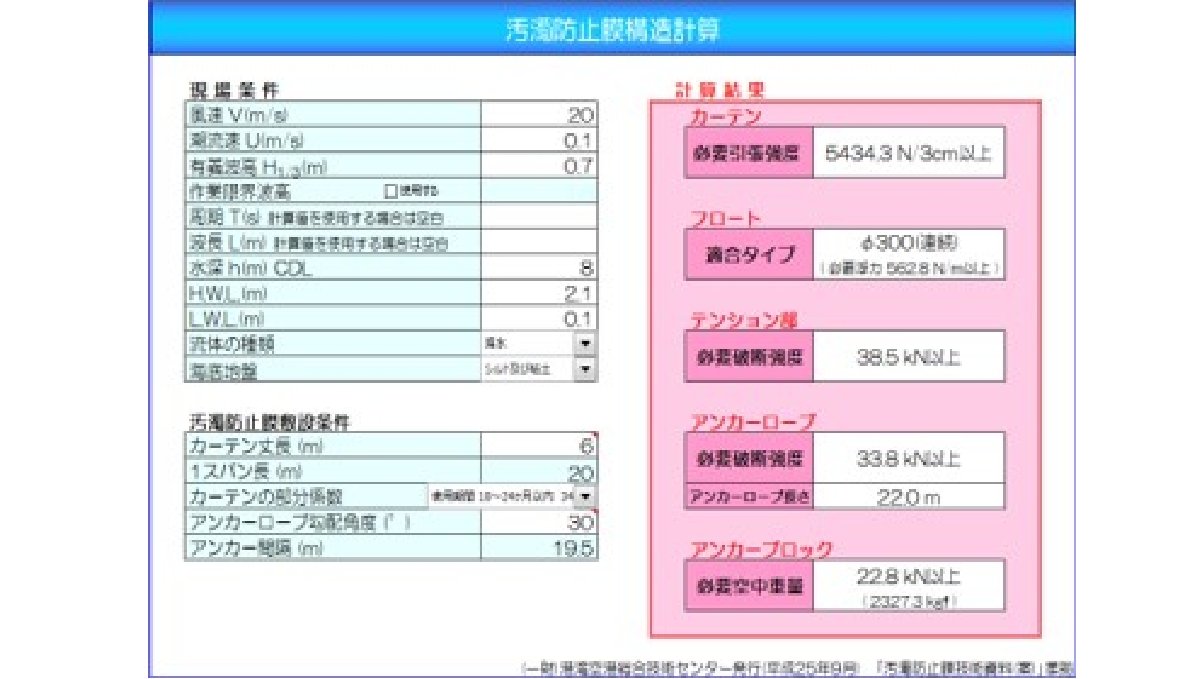

Structural calculations for anti-pollution membranes

After entering the site conditions such as wind speed, current speed, and water depth, the curtain strength will be output. The calculation sheet (Excel) can be downloaded from the link below.

Output contents

- curtain strength

- float required buoyancy

- required strength of tension section

- anchor block required weight

Structural Calculation of Pollution Control Membrane (Free Download)